The secondary air pump motor of vehicles is a device used to enhance emissions control and improve fuel economy. It usually connects with a car’s emissions system, adding extra air to the emissions to reduce pollution and promote chemical reactions in the catalytic.

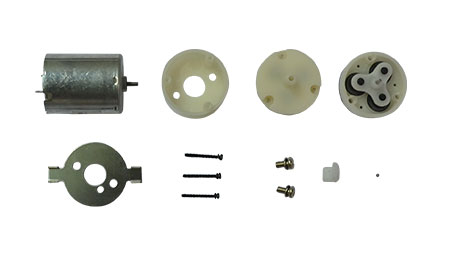

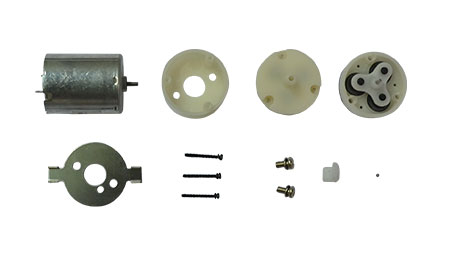

The components of the secondary air pump system

1. Air Filter: Filters incoming air to prevent dust and impurities from entering the system;

2. Secondary air pump: This component, driven by a motor, is responsible for compressing and transmitting air;

3. Engine Control Unit (ECU): The ECU manages the secondary air pump’s operation and adjusts the airflow according to the engine’s conditions to optimize performance and emissions control;

4. Secondary air control valve: It regulates the amount of air entering the exhaust system;

5. Secondary air mechanical valve: In some systems, used to further control the flow direction of air.

The working principle of the secondary air pump motor

The secondary air pump motor extracts fresh air from the atmosphere and delivers it into the exhaust system via a compact electric pump. In this process, the air is usually directed after the catalytic converter. This enhances the efficiency of the catalytic converter, particularly during cold starts. During a cold start, the exhaust gas produced by the engine is not hot enough to effectively activate the chemical reactions in the catalytic converter, so by injecting additional air, the “heating” process of the catalytic converter can be accelerated, allowing it to reach operating temperature faster.

The functions of the secondary air pump motor

1. Reduce exhaust emissions: The secondary air pump facilitates the oxidation of harmful substances, such as unburned hydrocarbons and carbon monoxide, converting them into less harmful carbon dioxide and water vapor;

2. Enhance catalytic converter efficiency: The secondary air pump maintains the catalytic converter’s optimal operating temperature, essential for efficiently converting pollutants into less harmful substances. It aids in quickly reaching the required temperature after engine start-up, thereby boosting efficiency.

3. Promote emission control during cold starts: During cold starts, the combustion efficiency of the engine is usually low, and the exhaust gas produced is not hot enough to activate the catalytic converter. The secondary air pump is particularly important at this time because it can begin to reduce harmful emissions before the catalytic converter reaches the ideal operating temperature;

4. Maintain air quality: The secondary air pump helps maintain better air quality by improving the combustion process and reducing incompletely burned fuel;

5. Support vehicles to pass emission tests: Since the secondary air pump helps reduce exhaust emissions, it also supports vehicles to pass strict emission tests;

6. Extended catalytic converter life: By ensuring that the catalytic converter operates at optimal temperatures, the secondary air pump helps reduce damage to the catalytic converter due to high temperatures, thereby extending its service life.

The application of secondary air pump motors in the automotive field is mainly concentrated in secondary air injection systems. It is a key component of the secondary air injection system. This system is designed to reduce automobile exhaust emissions and improve the efficiency of three-way catalytic converters.

Advantages of secondary air pump motors

1. High efficiency and quick response: The secondary air pump, driven by a brushless motor, is characterized by high speed and quick response, effectively delivering fresh air into the engine’s exhaust pipe to promote the further oxidation and combustion of harmful substances;

2. Environmental protection effect: By providing jet airflow, the secondary air pump helps the three-way catalytic converter reach the operating temperature as early as possible, thereby reducing the emission of harmful substances in the exhaust and playing an environmental protection role;

3. Reduce wear and maintenance needs: The design of the brushless motor eliminates the friction resistance of the brushes, reducing maintenance needs and wear problems, thereby extending the service life of the motor;

4. Improve engine performance: The secondary air pump can enable the engine to enter the air-fuel ratio closed-loop control process faster and improve the engine’s working performance;

5. Flexible control system: The brushless motor controller can use independent power control, or can use power control or a combination of control signals for collaborative control, providing more control strategy options.

Disadvantages of secondary air pump motors

1. Cost issue: The installation and replacement of the secondary air pump may increase the manufacturing cost of the car;

2. Increased complexity: Brushless motor control systems are relatively complex and require precise electronic control units and complex circuit designs, which may increase the difficulty of maintenance and diagnosis;

3. Noise and vibration issues: In some cases, the operation of the secondary air pump may produce additional noise and vibration.

Market development forecast in 2024 of secondary air pump motor

A. Market size growth

It is speculated that the market size of secondary air pump motors will continue to grow, driven by global demand to reduce vehicle exhaust emissions and provide fuel efficiency. With the increasingly stringent environmental regulations and the pursuit of clean energy and low-emission technologies, the market demand for secondary air pump motors, as a key component to improve vehicle emission efficiency, is expected to increase significantly.

B. Regional market dynamics

1. Asia-Pacific Market

The Asia-Pacific region, especially the Chinese market, is expected to play a more important role in the coming years. As one of the world’s largest automotive markets, China’s demand for secondary air pump motors is expected to grow rapidly.

2. North American Market

The market in North America is expected to maintain stable growth, due to the region’s stringent environmental protection regulations, demand for fuel efficiency, and the established foundation of its automotive industry.

3. European Market

The European market will also be an important market for secondary air pump motors. Strict emission standards and the pursuit of clean energy technology will drive the development of the market in this region.

4. South American Market

The South American market is expected to witness growth in the secondary air pump motor sector, particularly with the expansion of the automotive industry in countries such as Brazil and Argentina.

5. Middle East and Africa Market

Despite its current smaller size, the Middle East and Africa market is projected to grow due to economic and infrastructure advancement, driving the demand for secondary air pump motors.

If you are interested in air pump motor assembly line or need air pump motor assembly equipment, welcome to consult now to get customized solutions and quotes. HONEST Automation has many successful cases of air pump motor assembly equipment.