An air pump is a device used to remove air from a closed space or add air from a closed space. It is mainly divided into electric air pumps, manual air pumps, and foot-operated air pumps.

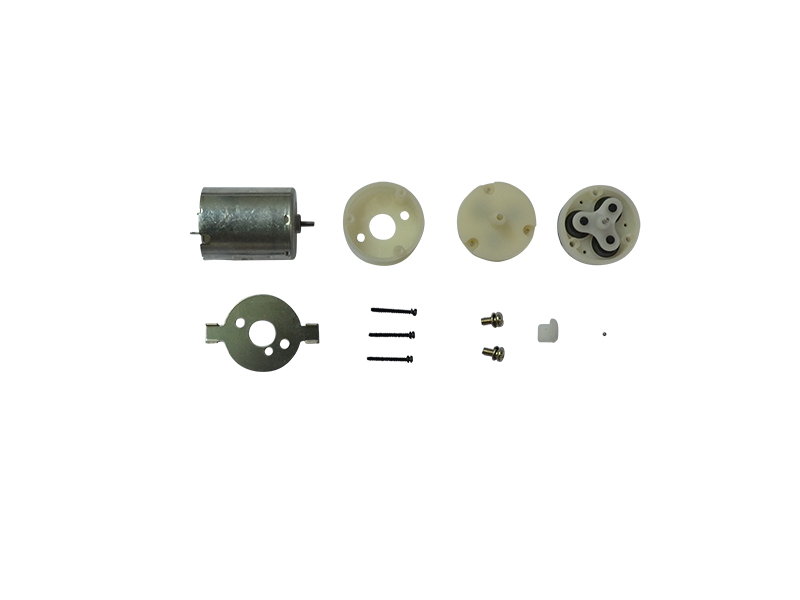

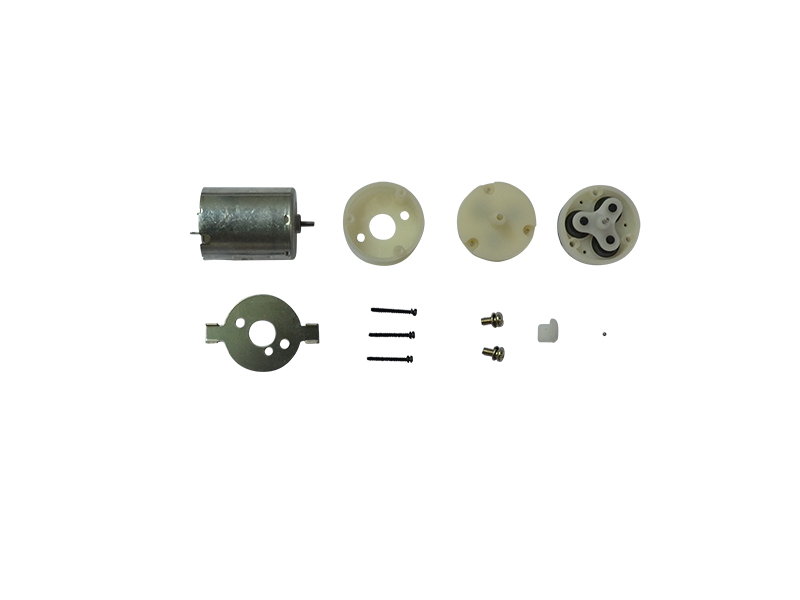

The Structure of Air Pumps

The main components of an air pump usually include the following parts:

1. Motor: It is the core structure of the electric air pump. Its power and speed will directly affect the inflation speed and efficiency of the air pump;

2. Pump Body and Cylinder: The pump body is the shell of the air pump, which protects the internal components and withstands the pressure generated by the compressed air. The cylinder is a sealed space inside the pump body, allowing the piston to reciprocate inside it;

3. Piston: It is a moving part in the cylinder that compresses air through reciprocating motion;

4. Valve: The intake valve opens when the piston moves downward, allowing air to enter the cylinder, and the exhaust valve opens when the piston moves upward, releasing the compressed air to the air storage tank or directly output;

5. Air Nozzle and Hose: The air nozzle is used to connect the air pump to the object requiring inflation, such as tires or air mattresses. The hose serves as the conduit between the air nozzle and the pump, typically constructed from materials designed to withstand pressure and resist wear;

6. Pressure Regulator: The pressure regulator is used to set and maintain the compressed air pressure output by the air pump. It ensures that the air pump automatically stops when the preset pressure is reached to prevent over-inflation or tire blowout.

These components ensure that the air pump can effectively and safely provide compressed air for various applications. When designing, the compatibility and overall performance of each component need to be considered to meet different usage needs and environmental conditions.

How the Air Pump Works

The engine drives the crankshaft of the air pump through two V-belts, thereby driving the piston to pump air. The pumped gas is introduced into the air reservoir through the air guide pipe. On the other hand, the air reservoir introduces the gas in the air reservoir into a pressure-regulating valve fixed on the air pump through an air guide tube, thereby controlling the air pressure in the air reservoir. When the air pressure in the air reservoir does not reach the pressure set by the pressure regulating valve, the gas entering the pressure regulating valve from the air reservoir cannot open the pressure regulating valve; when the air pressure in the air reservoir reaches the level at which the pressure regulating valve opens, it manages the air inlet of the air pump to remain open via the air channel. This allows the air pump to operate without a load, reducing power consumption and protecting the pump from potential damage. When the air pressure in the air reservoir is lower than the pressure set by the pressure regulating valve due to loss, the valve in the pressure regulating valve is returned by the return spring, disconnects the control air path of the air pump, and the air pump starts pumping air again.

Electric Air Pump VS Manual Air Pump VS Foot-operated air pump

Definition

Electric Air Pump: it is an air pump powered by electricity, which continuously compresses air through electricity to generate air pressure;

Manual Air Pump: it is an air pump powered by hand power, which continuously compresses air to generate air pressure;

Foot-operated Air Pump: it is an air pump powered by foot power, which continuously compresses air through foot power to generate air pressure.

Electric Air Pump

A. Advantages

1. Automated Operation: The electric pump is driven by an electric motor, and the user only needs to press the switch to start, making it easy to operate;

2. High Efficiency: It usually has a faster inflation speed and is suitable for occasions where rapid inflation is required;

3. Continuous Operation: It can work continuously for a long time and is suitable for industrial production and large-scale applications;

4. Labor Saving: No manual operation is required, reducing labor intensity.

B. Disadvantages

1. power Supply Dependence: It requires a stable power supply and is not suitable for environments without a power supply;

2. Maintenance Costs: Electric Motors may require regular maintenance and replacement;

3. Noise Problem: The electric air pump may produce a certain amount of noise during operation.

C. Application Fields

1. Industrial Production: It is often used in automated production lines to provide power sources for various mechanical equipment, such as pneumatic tools, cylinders, and so on;

2. Medical Equipment: In the medical field, it is used to provide stable pressure for ventilators, infusion pumps and other medical equipment;

3. Automobile Maintenance: It is used for inflating automobile tires and spray guns in automobile spray painting operations;

4. Cleaning Equipment: It is used for various cleaning tools, such as pneumatic vacuum cleaners, high-pressure cleaners, and so on.

Manual Air Pump

A. Advantages

1. Portability: It is usually small in size, light in weight and easy to carry;

2. No power supply required: It does not rely on power supply and can be used in any environment;

3. Economical: The price is cheaper, maintenance and repair are relatively easy and the cost is low.

B. Disadvantages

1. Labor intensity: Manual operation is required, and long-term use may cause fatigue;

2. Slow inflation speed: Compared with the electric air pump, the inflation speed is slightly slower;

3. Low efficiency: For large or frequent inflation needs, the efficiency is not high.

C. Application Fields

1. Outdoor activities: used to inflate inflatable mattresses and tents during camping, hiking, and other activities;

2. Small maintenance work: for household or small maintenance work, used to inflate bicycle tires, balls, etc.;

3. Emergency backup: As a backup inflatable solution in a power outage or no power supply environment.

Foot-operated air pump

A.Advantages

1. Ergonomic design: using pedal power to reduce the labor intensity of the upper body;

2. Stability: Foot operation provides a more stable inflation force, suitable for occasions where uniform inflation is required;

3. No power supply required: It does not rely on power supply and is suitable for outdoor or non-power supply environments

B. Disadvantages

1. Labor intensity: Although the burden on the upper body is reduced, the feet are tired after long-term use;

2. Inflation speed: Compared with the electric air pump, the inflation speed is slower;

3. Space requirements: Sufficient space is required for installation and operation

C.Application fields

1. Sports facilities: used for inflating and maintaining large inflatable toys, inflatable swimming pools, etc. in sports venues;

2. Agriculture: In the agricultural field, used for inflation and ventilation of large greenhouses;

3. Industrial application: used in some industrial equipment that may require a foot-operated air pump to provide stable pressure.

When selecting an air pump, factors such as actual application requirements and environmental conditions should be considered. Electric air pumps are suitable for industrial and commercial environments that require fast and efficient inflation; manual air pumps are suitable for personal use with high portability requirements and infrequent inflation needs; foot-operated air pumps are suitable for specific occasions with stable inflation strength and large inflation volume.

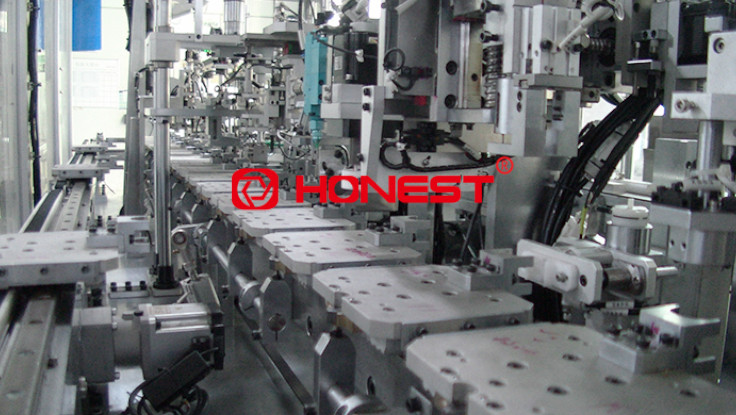

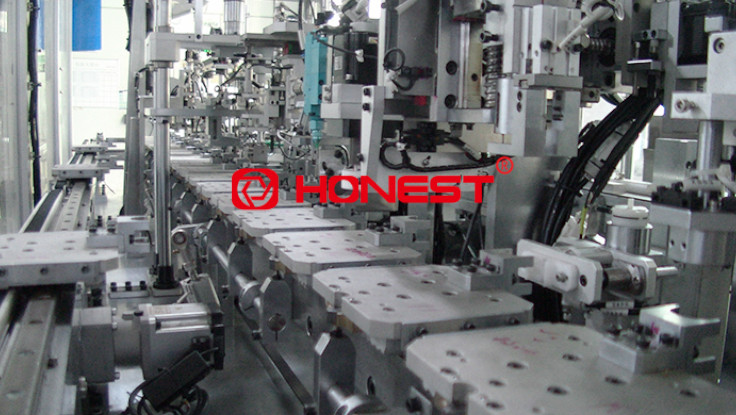

The picture above is HONEST Automation’s air pump production line. Should you require further information on HONEST Automation’s automatic air pump production line or other air pump production equipment, please do not hesitate to contact us at your earliest convenience.