As global regulations on fuel consumption and emissions become increasingly stringent, automakers are under pressure to innovate cost-effective and reliable hybrid solutions. Among these, 48V mild hybrid technology has emerged as a popular choice due to its balance of efficiency, simplicity, and affordability. At the heart of this system lies the BSG motor—the Belt Starter Generator—offering a compact yet powerful enhancement to conventional internal combustion engines.

In this article, we will explore what a BSG motor is, its role in hybrid systems, and how HONEST Automation's automated BSG motor stator assembly line is helping global manufacturers meet modern demands for performance and scalability.

Understanding the BSG Motor in a 48V Mild Hybrid System

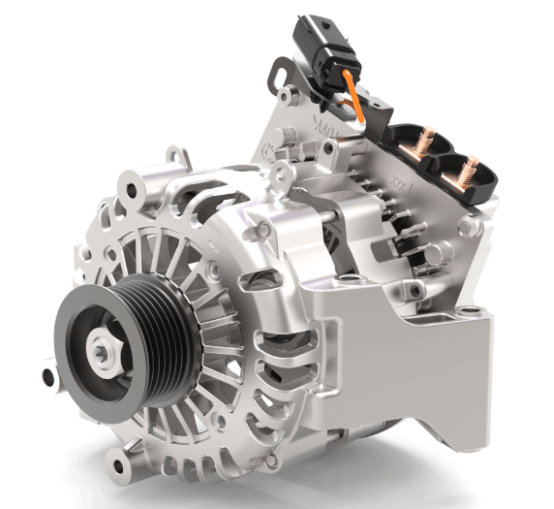

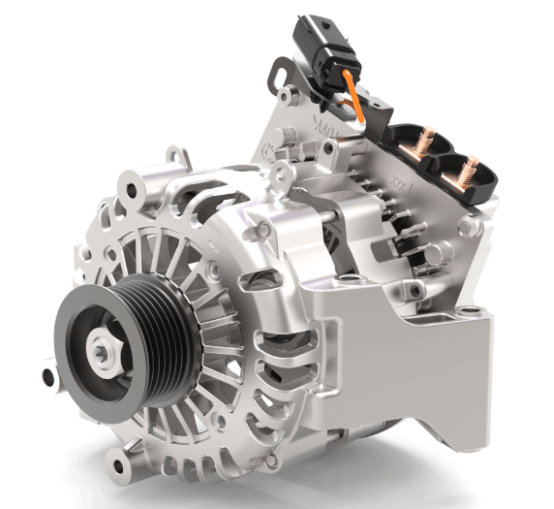

The BSG motor, or Belt Starter Generator, is a type of electric motor mounted at the front end of the engine and connected via a belt drive to the crankshaft. Unlike conventional starter motors, the BSG motor is multifunctional: it starts the engine, assists in acceleration, enables regenerative braking, and helps smooth out start-stop operations. This configuration is often referred to as the P0 hybrid architecture.

Key Functions of a BSG Motor:

Start/Stop Functionality: Smooth and silent restarting of the engine during stop phases.

Torque Assist: Provides additional torque during acceleration, reducing engine load.

Regenerative Braking: Converts kinetic energy into electricity during braking.

Battery Charging: Acts as a generator to recharge the 48V lithium-ion battery pack.

Because the BSG motor operates in tandem with the combustion engine and cannot drive the vehicle independently, it is categorized as a mild hybrid system. However, it plays a crucial role in improving fuel economy by up to 15% and reducing CO₂emissions—especially valuable in compact and mid-size vehicle platforms.

The Role of the Stator in BSG Motor Performance

At the core of the BSG motor lies the stator, a critical component responsible for generating the rotating magnetic field that powers the rotor. The precision and quality of the stator assembly directly affect the motor’s torque output, efficiency, and operational reliability.

Given the increasingly compact and high-speed design of 48V systems, manufacturers face growing challenges in ensuring:

High winding density with consistent tension

Secure coil insertion and reliable insulation

Uniform stator slot filling and lacing

Comprehensive quality inspection under high-volume production

This is where HONEST’s advanced stator assembly equipment makes the difference.

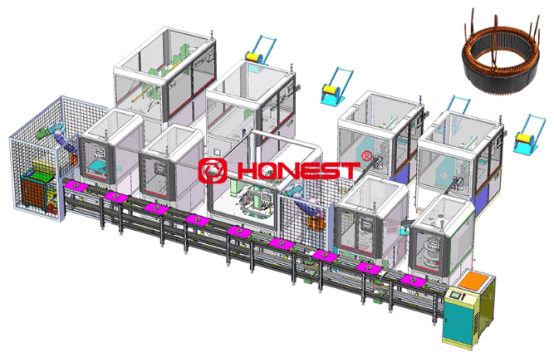

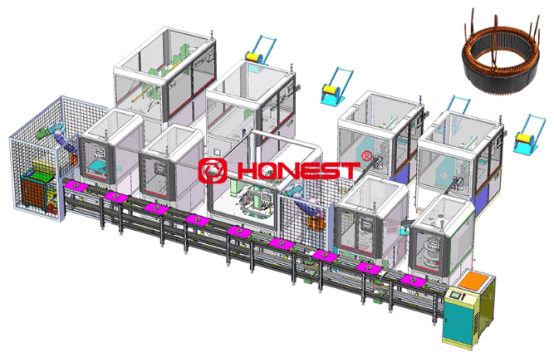

HONEST’s 48V BSG Motor Stator Assembly Line: Automation Meets Precision

HONEST provides a fully automated stator assembly line specifically designed for 48V BSG motors. Engineered for precision, speed, and modularity, our equipment is trusted by global OEMs and Tier 1 suppliers.

Key Features of the HONEST Automation BSG Stator Assembly Line:

High-speed winding stations with automatic wire cutting and tension control

Automated coil insertion into stator slots with minimal deformation

Integrated lacing and forming units for consistent mechanical integrity

100% inline testing for electrical properties and insulation quality

Modular and scalable design, adaptable to different motor specifications

Real-time data monitoring and MES integration for Industry 4.0 compatibility

Whether you are producing 100,000 units a year or scaling to millions, our solutions are built to grow with your production goals.

Why Choose HONEST Automation as Your Motor Assembly Partner?

At HONEST Automation, we specialize in motor winding and assembly automation equipment, with a particular focus on automotive applications. With over 19 years of experience and a strong portfolio of projects with top global clients, we offer:

Tailored engineering solutions for BSG, ISG, PMSM, and automotive brushed and brushless motors.

Turnkey equipment integration with on-site commissioning and training.

Localized support services for global operations.

Expert technical consulting throughout the R&D and production lifecycle.

Our equipment is already serving leading automotive OEMs and component manufacturers across Asia and Europe.

Request Your Customized Solution Today

As the automotive industry accelerates its transition to hybrid and electric mobility, the demand for efficient motor manufacturing equipment is growing rapidly. HONEST Automation 48V BSG motor stator assembly solutions provide the quality, consistency, and scalability you need to stay ahead in this competitive landscape.

Contact our team today for a customized proposal and pricing tailored to your product specifications. Our engineering experts are ready to support you from concept to commissioning.