Definition of the wiper motor:

The wiper motor is driven by the motor, through the linkage mechanism will be the rotary motion of the motor into the reciprocating motion of the scraping arm, to achieve the wiper action, generally connected to the motor, you can make the wiper work, through the selection of high speed and low-speed gears, you can change the size of the motor’s current, to control the motor’s speed and thus the scraper arm speed.

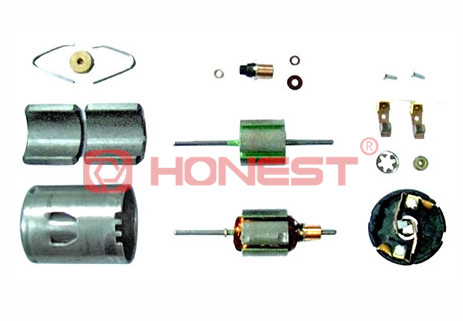

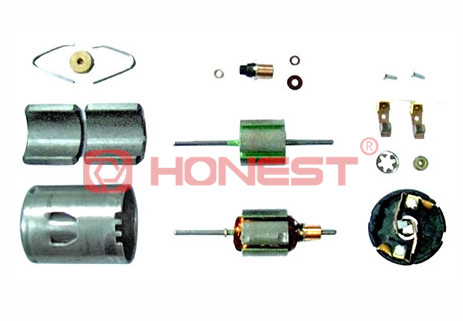

The main components of the wiper motor:

A. Motor: the wiper motor is the power source of the wiper, it usually uses a DC motor;

B. Transmission: it has a high rotational speed, which needs to be reduced through the transmission to adapt to the wiper’s rotational speed requirements.

C. Transmission Mechanism: the rotation of the wiper motor needs to be transmitted to the wiper through the transmission mechanism.

D. Control Device: it is used to control the speed and operating mode of the wiper motor

The working steps of the wiper motor:

1. Motor Rotation: when the driver turns on the wiper switch, an electric current flows through the motor, causing it to start rotating. This motor is usually a DC motor, the speed of which can be adjusted as needed;

2. Motion Conversion Mechanism: the rotary motion of the motor is converted to reciprocating linear motion by a set of gears and linkage mechanisms. This conversion usually includes the following parts;

A. Reduction Gear: reduce motor speed and increase output torque;

B. Crank Connecting Rod Mechanism: converts the rotational motion of the motor into the reciprocating linear motion of the wiper swing arm;

C. Swing Arm and Transmission Rod: connected to the wiper device, directly driving the wiper blade to swing back and forth.

3. Speed Control: wiper motors typically have several different speed settings, which allow the driver to adjust the speed of the wipers based on the amount of rain or other obstructions to their vision. In some systems, this is accomplished by varying the voltage supplied to the motor or by varying the current;

4. Parking Mechanism: when the wipers are turned off, the motor needs to park the wipers in a position that does not interfere with the driver’s vision. It is usually accomplished by using a limit switch or similar sensor to ensure that the wipers return to the parked position.

5. Intermittent Operation: many modern cars are also equipped with an intermittent operation mode, which allows the wipers to pause for a certain period between swings. It is controlled by an electronic timer or intermediate relay.

In simple terms, the working principle of the wiper motor is to convert the rotational motion generated by the motor into the reciprocating linear motion of the wiper through a mechanical linkage device, thereby achieving the function of cleaning the windshield.

There are certain manufacturing difficulties in wiper motors, as follows:

A. High Precision Requirement: the rotor bearing of the wiper motor needs to have high precision to ensure stable speed and smooth rotation of the wiper;

B. High Material Requirements: the rotor bearing of the wiper motor needs to be made of wear-resistant and corrosion-resistant materials to ensure its normal operation in harsh environments;

C. High Process Requirements: the manufacturing process of the wiper motor needs to be precise to ensure its good performance and service life.

To improve the manufacturing level and reliability of wiper motors, we can start from the following aspects:

A. Improve Material Performance: use more wear-resistant and corrosion-resistant materials, such as ceramic bearings or tungsten carbide bearings, to improve the service life of the wiper motor;

B. Improve the Manufacturing Process: use advanced manufacturing processes to improve the precision and reliability of the wiper motor;

C. Strengthen Quality Control: establish a complete quality control system, including raw materials, production processes, and finished product testing, and strictly control the quality of wiper motors to reduce failure rates.

The importance of wiper motor:

A. Improve Driving Safety: the wiper motor ensures that the wipers can work effectively to remove precipitation and pollutants from the windscreen, thus providing the driver with a clear line of sight. It helps avoid road accidents;

B. Extend Wiper Life: an efficient wiper motor ensures that the wipers work at the right speed and force to avoid shortening the life of the wipers due to excessive wear or pressure;

C. Enhance the Driving Experience: except for safety and legal requirements, wiper motors help improve the driving experience. A wiper motor that operates smoothly and quietly can reduce distractions while driving and make driving more enjoyable;

D. Responding to a wide range of weather conditions: wiper motors in modern cars often feature multiple speed settings and even automatic rain sensing to adjust the speed of the wipers to different weather conditions. This flexibility enhances the effectiveness of the wiper system and driver comfort.

Therefore, the wiper motor is a key component to ensure road safety and the driving experience. Regularly checking the function of your wiper system, including the wiper motor, will help keep it in good working order and ensure it’s functioning when needed.

Please feel free to contact us for any needs or questions regarding the manufacturing of wiper motor equipment or brush motor assembly line, we have professional technicians and proven customer cases, and I am confident that we can meet your requirements.