The introduction of the rotor:

The rotor is a rotating body supported by bearings. It is the part that rotates around a fixed center in the basic structure of electric motors, generators, gas turbines, and turbine compressors. According to ISO standards, the rotating body supported by bearings is called a rotor.

The rotor is mostly the main rotating component in power machinery and working machinery.

The main rotor rotates at high speed, and when its speed approaches the critical speed, the shaft will deflect and deform. Even mechanical damage due to resonance. The natural frequency of the rotor’s transverse vibration is multi-order, so its corresponding critical speed is also multi-order. When the rotor’s working speed is lower than the first-order critical speed, it is called a rigid rotor, and when the rotor’s working speed is higher than the first-order critical speed, it is called a flexible rotor.

The operating speed of any type of rotor must not be close to the critical speed. The critical speed of the rotor depends on its manufacturing materials, structural form, geometric dimensions, support characteristics, and other factors.

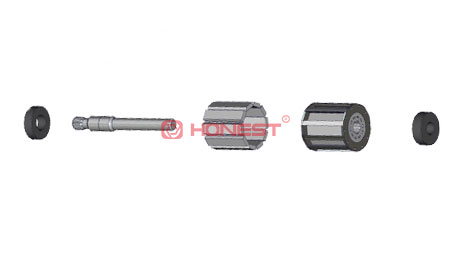

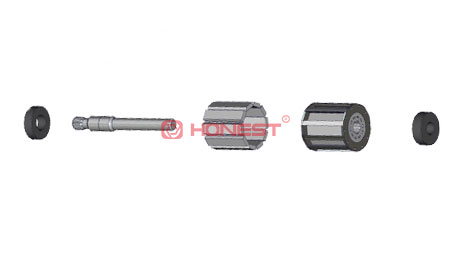

The structure of the rotor:

The rotor of the motor is generally composed of an iron core wound with coils, slip rings, fan blades, and so on.

1. Iron Core: it is the core part of the rotor, made of magnetically conductive materials, used to generate magnetic fields or cut magnetic fields. The rotor core is generally made of laminated silicon steel sheets to reduce eddy current losses;

2. Winding: it is the part of the rotor that carries current and is used to generate electromagnetic force or induced current. The rotor winding is generally made of laminated silicon steel sheets to reduce eddy current losses;

3. Other Components: there may also be collector rings, slip rings, fans, and so on, on the rotor.

The structure of the rotor directly affects the performance of the rotor, so reasonable selection needs to be made according to the specific requirements of the machine during the design and manufacturing process.

The classification of rotor:

The rotors are classified according to different classification standards, and the common ones are as follows:

1. Classification according to the working principle: electromagnetic rotor and mechanical rotor;

2. Classification according to structure: single-stage rotor, multi-stage rotor and step-less rotor;

3. Classification according to material: steel rotor, aluminum rotor, titanium rotor, and so on;

4. Classification according to shape: cylindrical rotor, conical rotor, impeller-shaped rotor, and so on.

The working principle of the rotor:

The specific working principle of the rotor will vary according to different mechanical types and working principles. The following are the specific working principles of some common rotors:

1. Motor Rotor: the winding of the wound motor rotor generates electromagnetic force through energization. When the electromagnetic force interacts with the stator's magnetic field, torque is generated, causing the rotor to rotate. The guide bars and guide grooves of the squirrel-cage motor rotor form a closed loop. When the rotor rotates, the conductor cuts the magnetic induction lines, which generates an induced current, which in turn generates electromagnetic force, causing the rotor to rotate;

2. Generator Rotor: the magnetic pole winding of the generator rotor generates a magnetic field by energizing it. When the magnetic field cuts the stator winding, an induced current will be generated. The direction of the induced current is opposite to the cutting direction of the magnetic field, and the size of the induced current is proportional to the strength of the magnetic field and the cutting speed;

3. Gas Turbine Rotor: the impeller of the gas turbine rotor generates rotational force due to the flow of gas, thereby causing the rotor to rotate. When the gas flows through the impeller, it will transfer energy to the rotor, the rotor will transfer the energy to the main shaft, and the main shaft will output the energy;

4. Turbocompressor Rotor: the turbocompressor rotor’s impeller compresses air or other gases by rotating. When the impeller rotates, air or other will be sucked into the impeller, compressed inside the impeller, and then discharged.

The specific working principle of the rotor directly affects the performance of the machine, so a reasonable selection needs to be made according to the specific requirements of the machine during the design and manufacturing process.

The rotor line

Brushless motor rotor assembly line

The brushless motor rotor assembly line of HONEST Automation has a high degree of automation and intelligence, supporting the MES system, through the product QR code, to achieve the production status of dynamic information kanban, scheduling, material distribution, process parameters, production quality data statistics and analysis, equipment operation status and maintenance management, quality traceability system of the factory information management.

The line mainly consists of rotor shaft coding, pressing into the iron core, cleaning, magnetization to measure the magnetic flux, bearing press-fitting, and other processes, using the belt conveyor line way to transfer materials.

Equipment Parameters:

A. Production Efficiency: 12s/pcs;

B. Exchange Time: 10minutes;

C. Utilization Rate: ≥90%;

D. Yield: ≥98%;

E. Air Pressure: 0.4MPa-0.65MPa;

F. Size: 4800(L)*1500(W)*2200(H)mm.

Drive Motor Rotor Production Line

The drive motor rotor production line of HONEST Automation adopts the MES manufacturing execution system, which provides the enterprise with management modules including manufacturing data management, production process control, underlying data integration and analysis, upper-level data integration and decomposition, and so on, to create a solid, reliable, comprehensive, a feasible manufacturing collaborative management platform.

The production line mainly consists of iron core loading→iron core inserting magnetic steel→mandrel press installation→rotor locking and riveting→rotor magnetization→rotor laser coding→rotor unloading and other processes.

This project is used to assemble drive motor rotors for new energy vehicles. The entire line adopts a modular design, with automatic loading and unloading by robots. The production line is highly flexible, providing a one-stop solution for the manufacturing of drive motors.

Equipment Parameters:

1. Production Efficiency: 128s/pcs;

2. Yield Rate: ≥98%;

3. Utilization Rate: ≥95%;

4. Air pressure: 0.4-0.6MPa;

5. Size: 32600(L)*12000(W)mm.

If you have any interest in our rotor assembly line, please feel free to contact us!