In the fast-evolving automotive landscape, electric vehicles (EVs) are no longer a futuristic concept—they are a reality reshaping transportation globally. At the heart of this transformation lies one essential component: the electric motor. Among various motor types, DC electric motors have become a preferred choice for many vehicle manufacturers. But why exactly are DC electric motors so widely used in vehicles today? In this article, we'll dive deep into the fundamentals, types, and key benefits of DC electric motors, helping you understand why they stand out in the world of automotive technology.

What Are DC Electric Motors?

A DC (Direct Current) electric motor is a device that converts direct electrical energy into mechanical motion. Unlike AC motors, which operate on alternating current, DC motors receive a constant voltage from sources like batteries. This makes them highly compatible with electric vehicles, which rely on battery packs as their primary energy source.

The fundamental working principle of a DC motor is based on Lorentz Force—when current flows through a conductor placed in a magnetic field, it experiences a force that causes rotation. This simple yet effective design has made DC motors a staple in automotive systems for decades.

Types of DC Electric Motors Used in Vehicles

Understanding the types of DC motors is crucial, as each offers specific advantages for different vehicle applications.

1. Brushed DC Motors

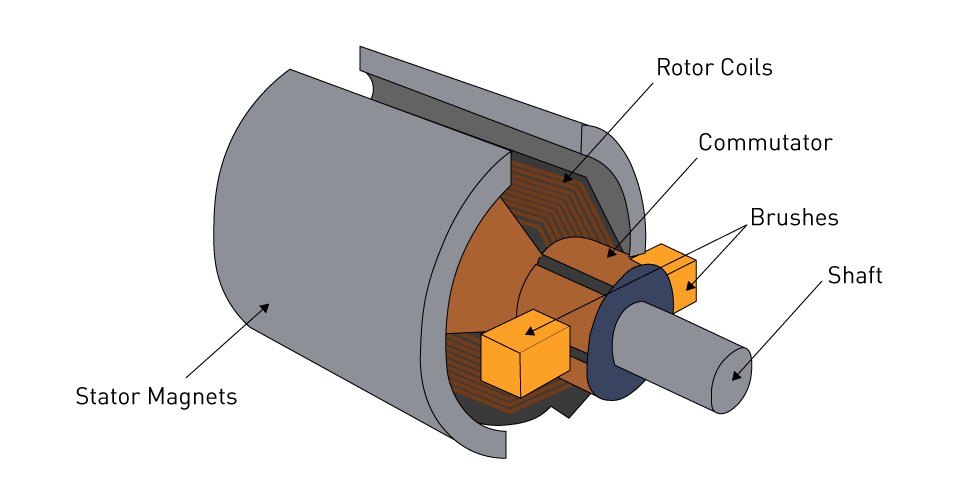

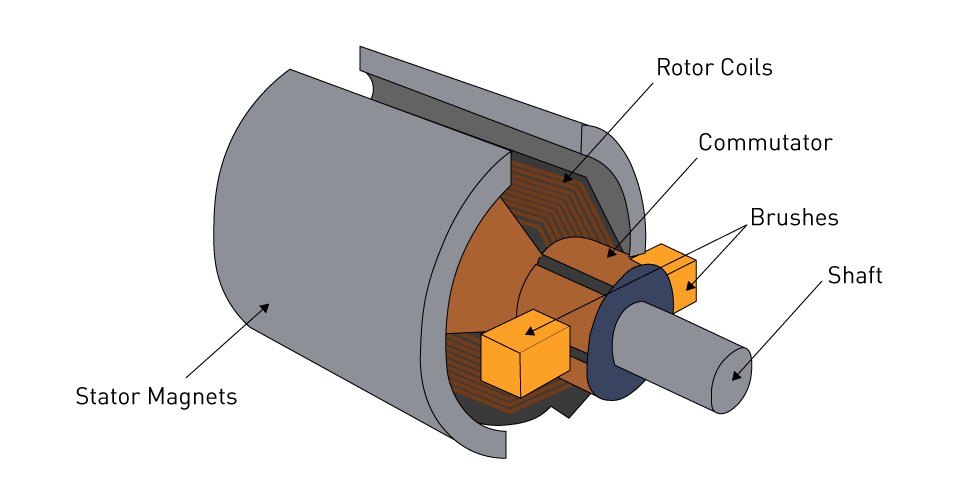

Brushed DC motors are the traditional, mechanically commutated motors. They use carbon brushes and a commutator to transfer electrical current to the rotor.

Key Features:

Simple and cost-effective

Easy speed control

Suitable for low to medium power applications

Applications:

Power windows

Windshield wipers

Seat adjusters

HVAC blower systems

Despite their simplicity, brushed motors require periodic maintenance due to brush wear.

2. Brushless DC Motors (BLDC Motors)

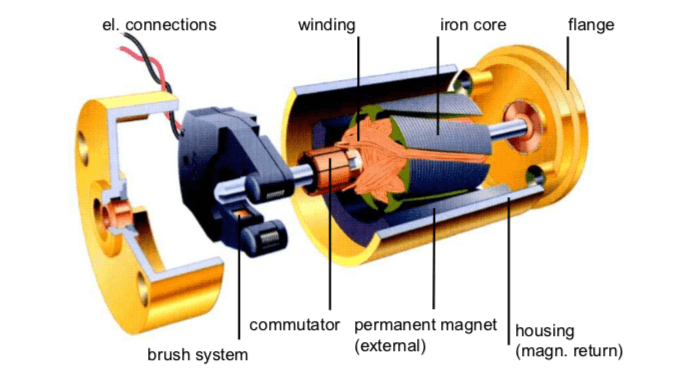

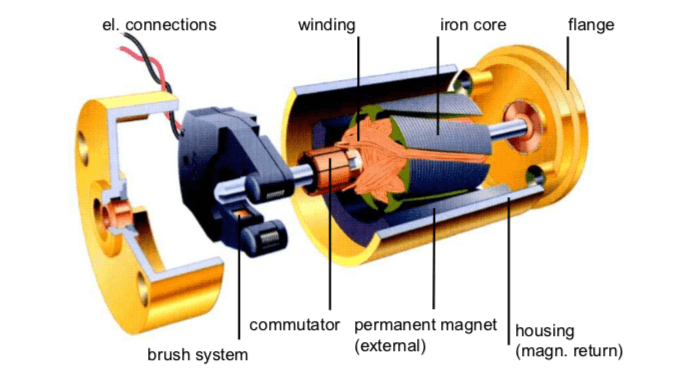

Brushless DC motors have emerged as a modern upgrade to brushed motors, eliminating the need for physical brushes by employing electronic commutation.

Key Features:

High efficiency and power density

Low noise and heat generation

Longer lifespan due to minimal wear

Applications:

Electric vehicle drivetrains

Electric power steering systems

Battery cooling fans

Autonomous driving components

BLDC motors are particularly well-suited for EVs because they offer smooth torque delivery and superior control.

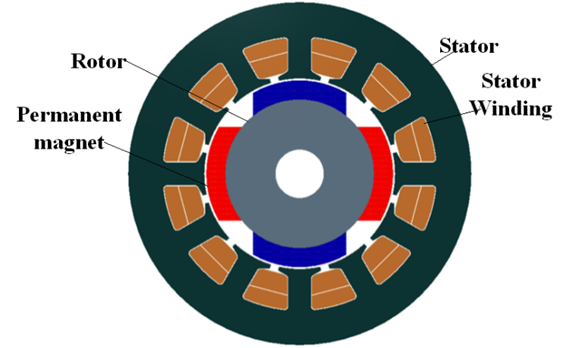

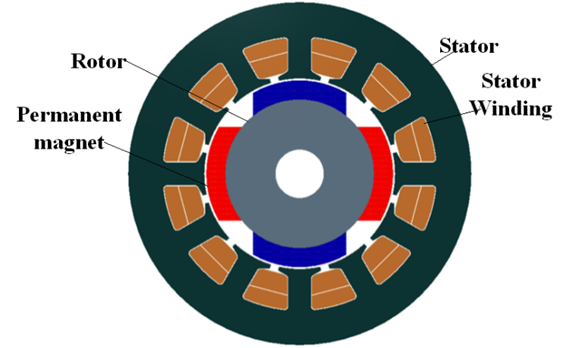

3. Permanent Magnet DC Motors (PMDC Motors)

PMDC motors use permanent magnets to establish a magnetic field, reducing size and simplifying the design.

Key Features:

Compact and lightweight

High starting torque

Easy to control

Applications:

Electric scooters and light EVs

Auxiliary automotive systems (like pumps and fans)

Key Benefits of Using DC Electric Motors in Vehicles

1. High Efficiency & Energy Savings

One of the standout advantages of DC electric motors, especially BLDC types, is their superior energy efficiency. With minimal electrical losses, these motors ensure that a higher percentage of battery power is effectively converted into mechanical motion. This directly translates to longer vehicle range—a critical factor in electric vehicle performance.

Moreover, efficient motors reduce the strain on battery systems, potentially extending battery life and lowering energy consumption per kilometer.

2. Precise Speed and Torque Control

DC motors excel in delivering precise, linear control over speed and torque, which is vital for modern vehicles. Whether it's smooth acceleration, regenerative braking, or variable load conditions, DC motors allow real-time adjustments with high accuracy. This level of control enhances the driving experience, ensuring both comfort and safety.

In comparison, AC motors often require more complex inverters and control algorithms to achieve similar levels of finesse.

3. Compact & Lightweight Design

In vehicle design, every kilogram counts. DC electric motors, particularly PMDC and BLDC motors, offer a high power-to-weight ratio and a more compact footprint. This not only frees up space within the vehicle chassis but also contributes to overall vehicle weight reduction, which in turn improves efficiency and performance.

This makes them ideal for applications where space constraints are a concern—such as electric scooters, compact EVs, and even in autonomous delivery robots.

4.Low Maintenance & Long Lifespan

Thanks to fewer mechanical parts, especially in brushless configurations, DC motors demand significantly less maintenance compared to traditional internal combustion engine (ICE) systems or brushed motors. The absence of brushes reduces mechanical wear, leading to lower maintenance costs and fewer downtimes.

This benefit is particularly attractive to fleet operators and end-users seeking long-term reliability and reduced total cost of ownership (TCO).

5. Environmentally Friendly

As the world shifts toward sustainable mobility solutions, DC electric motors play a crucial role. Since they operate on electricity—especially when powered by renewable energy sources—they contribute to zero tailpipe emissions, reducing greenhouse gas output and air pollution.

Additionally, the efficiency of DC motors helps minimize overall energy consumption, supporting global efforts toward carbon neutrality and cleaner urban environments.

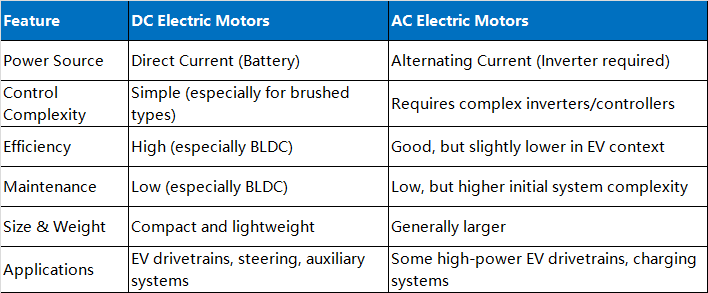

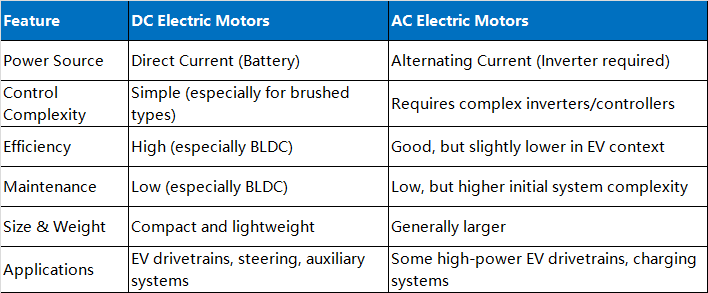

DC Electric Motors vs. AC Electric Motors: Quick Comparison

While AC motors are also used in certain EV applications, DC electric motors remain a top choice for their simplicity, efficiency, and integration ease, particularly in light to medium-duty vehicles and auxiliary systems.

Common Applications of DC Electric Motors in Vehicles

Beyond propelling vehicles, DC motors are deeply integrated into numerous automotive subsystems:

Main Drive Motors: Especially in small to medium-sized electric vehicles and hybrid vehicles.

Electric Power Steering (EPS): Providing reliable, responsive steering assistance.

HVAC Systems: Powering fans and blowers.

Window Lifts, Wipers, and Seat Adjusters: Enhancing driver and passenger comfort.

Emerging Applications: Key roles in autonomous driving technology, battery management systems, and advanced driver assistance systems (ADAS).

The automotive industry's shift toward electrification has placed DC electric motors at the forefront of innovation. Their combination of high efficiency, precise control, compact design, and low maintenance makes them an ideal choice for modern vehicles seeking sustainable, reliable, and cost-effective solutions.

Whether it's powering the main drivetrain or enhancing vehicle comfort systems, DC electric motors continue to shape the future of mobility. For manufacturers and engineers aiming to stay competitive, understanding the advantages of DC motor technology is more critical than ever.

Interested in integrating advanced DC motor automation equipment into your vehicle manufacturing process? As a leading provider of motor winding machine, we specialize in delivering customized winding solutions for automotive motors and DC motor assembly lines. Our expertise spans a wide range of applications, including automotive drive motors, EPS motors, fan motors, oil pump motors, starter motors, water pump motors, ABS pump motors, compressor motors, and automotive transmission motors.

Our team is committed to delivering tailored solutions and one-stop services, ensuring the efficiency and precision of your production lines.

Contact us today for a consultation and discover how we can enhance your motor assembly processes.