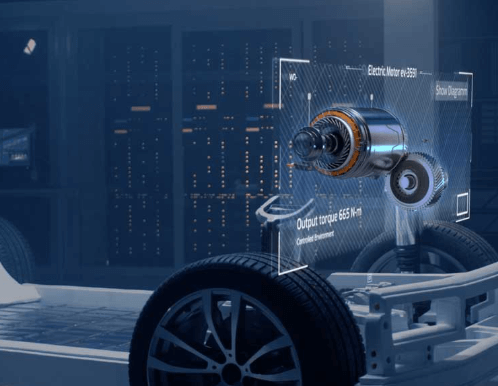

1. The New Challenge in EV Motor Manufacturing

The global electric vehicle (EV) market is expanding at an unprecedented rate, and the demand for high-performance electric motors is growing rapidly. While the early competition in the EV industry focused primarily on motor efficiency, torque output, and power density, a new challenge has emerged: scaling production to meet growing market demand while maintaining quality and consistency.

Manufacturers now face a dual challenge: not only designing motors that meet rigorous performance standards but also building manufacturing systems capable of producing thousands—or even millions—of motors consistently and efficiently. This transition from performance-centric to production-centric competition is reshaping the way top EV motor manufacturers operate, from prototype development to mass production.

2. From Prototype to Mass Production: Common Misconceptions

A frequent misconception in the EV motor industry is that a motor that works perfectly in a prototype can be scaled to mass production with minimal effort. In reality, prototype success rarely translates directly to production success.

Key Gaps Between Prototype and Mass Production:

Manual processes in prototypes often cannot be replicated at scale without introducing variability.

Tolerance and quality expectations in mass production are much stricter than in prototypes.

Process integration is critical—isolated processes may work individually but fail when combined in a high-volume line.

Top EV motor manufacturers understand that industrialization requires early planning for scalability, automation, and process repeatability, rather than reacting to challenges after the prototype stage.

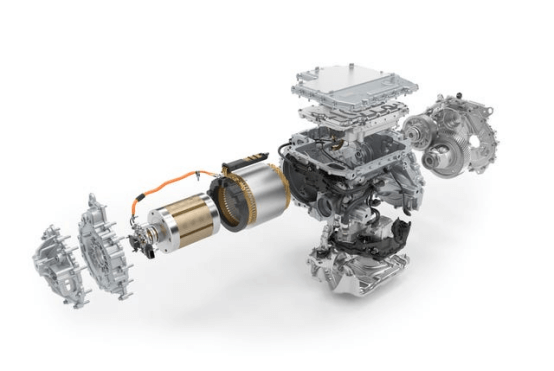

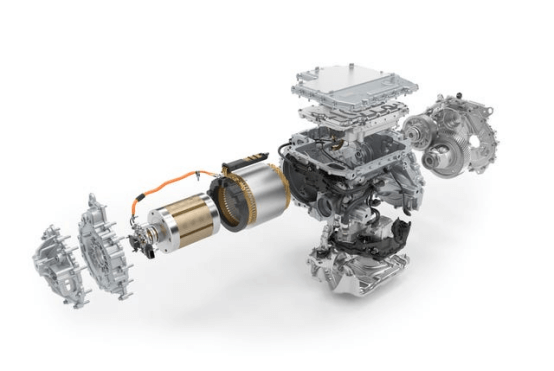

3. Key Technical Challenges in Scaling EV Motor Production

Scaling EV motor production introduces several technical challenges that must be addressed to achieve high-volume output without compromising quality.

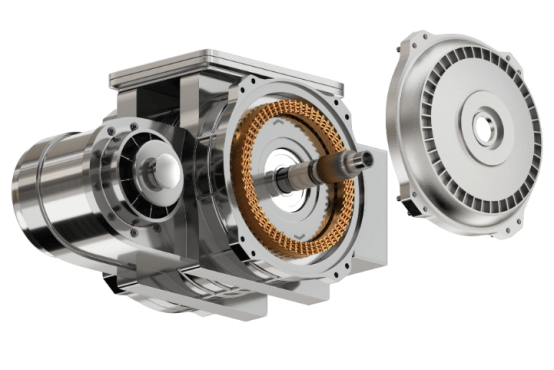

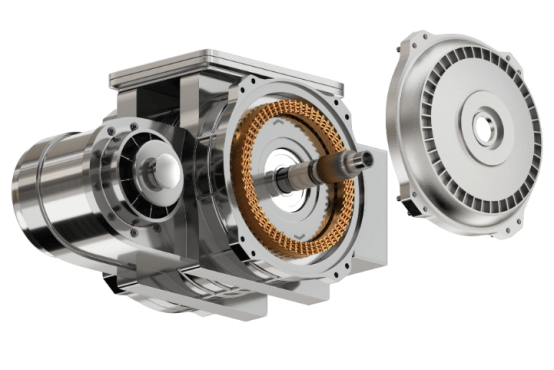

3.1 Stator Winding Complexity

Modern EV motors increasingly use advanced winding techniques such as hairpin winding, segmented winding, or high slot-fill round wire designs. These approaches improve efficiency, thermal performance, and electromagnetic characteristics, but they significantly increase production complexity.

Challenges include:

Precise insertion of hairpins to avoid misalignment

Consistent insulation and epoxy impregnation

Managing thermal expansion and tolerances across large batches

3.2 Rotor Assembly and Magnet Insertion

Rotor assembly, including magnet insertion, bonding, and balancing, is critical to motor performance. High-volume production requires:

Automated handling of delicate magnets

Accurate alignment and mechanical stability

Integrated inspection to catch defects early

Without automation, variability in rotor assembly can lead to electrical imbalance, vibration, and long-term reliability issues.

3.3 Welding and Connection Reliability

Processes such as terminal welding, star point connections, and end-ring joining are especially sensitive in high-volume production. Small inconsistencies can result in:

Resistance imbalance

Excessive heat generation

Reduced long-term reliability

Manufacturers must implement precise process controls, automated welding, and inline inspection to maintain consistent electrical and mechanical performance.

3.4 Process Consistency and Yield

High-volume production magnifies small deviations. Consistency across batches is critical to maintaining yield and reducing scrap. Leading manufacturers implement:

Real-time monitoring of critical parameters

Inline testing of electrical and mechanical properties

Process analytics to identify and eliminate variability

3.5 Labor Dependency and Cost Constraints

Manual operations introduce variability and limit throughput. Labor-intensive processes can also lead to higher costs, especially in regions with skilled labor shortages.

Automation helps reduce reliance on human operators, ensuring:

Stable output quality

Predictable production capacity

Lower long-term operational costs

4. How Automation and Advanced Production Systems Help

High-volume EV motor production is only possible with integrated automation and advanced production systems. These systems enable manufacturers to maintain quality, scale efficiently, and reduce cost per unit.

4.1 Inline Quality Inspection

Automated inspection systems embedded within the production line detect defects immediately, allowing for real-time correction and minimizing scrap.

4.2 Production Line Integration

Integrating processes such as winding, rotor assembly, welding, and final testing into a seamless production line improves throughput and reduces variability.

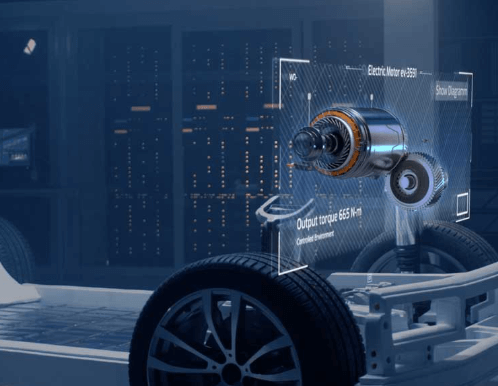

4.3 Data Traceability and Process Control

Digitization allows manufacturers to monitor each production step, analyze deviations, and optimize performance. Traceable data supports continuous improvement and regulatory compliance.

5. Lessons Learned from Industry Leaders

Top EV motor manufacturers consistently demonstrate the following patterns:

Early automation planning to ensure scalability

Modular production lines for flexibility and throughput optimization

Design for manufacturability integrated into R&D

Collaboration with automation partners for system-level integration

By observing these practices, emerging manufacturers can reduce risks during industrialization and accelerate ramp-up times.

6. Key Takeaways for Emerging Manufacturers

Emerging EV motor manufacturers face steep challenges in scaling production. Key strategies for success include:

Planning production systems early, alongside motor design

Prioritizing automation and process repeatability over short-term cost savings

Partnering with experienced automation and integration specialists

Ensuring flexibility in production lines to accommodate future motor variants

These lessons help companies avoid costly errors and achieve consistent, high-volume output efficiently.

7. Scaling Is a System, Not a Single Process

Scaling EV motor production is not about individual machines or isolated processes. Success requires a well-designed, integrated production system that balances performance, quality, and scalability.

Experienced automation partners play a critical role in bridging the gap between motor design and mass production, providing expertise in stator winding, rotor assembly, and full-line integration.

For manufacturers seeking to lead in the high-volume EV motor market, industrialization strategy and system-level thinking are as important as motor design itself.