The traction motor industry is a capital-intensive sector, where production relies heavily on automated manufacturing lines. Fixed asset investment requirements are substantial, with approximately USD 9.7 million required for every 100,000 units of production capacity.

Looking ahead, higher operating speeds, hairpin winding, system integration, and oil-cooling technologies are key trends shaping the future development of drive motors.

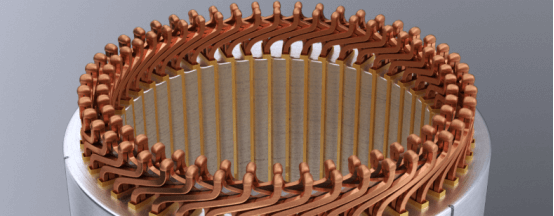

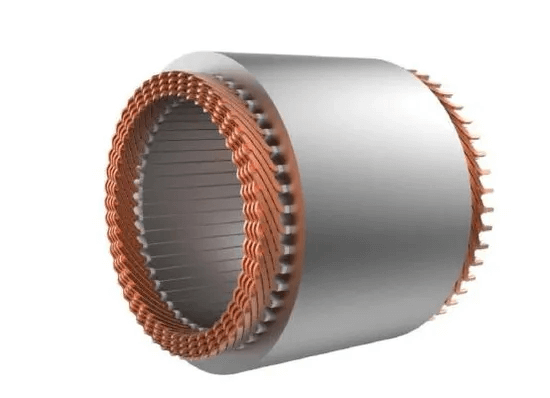

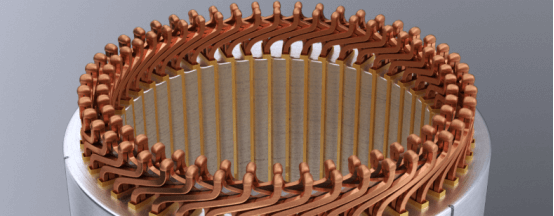

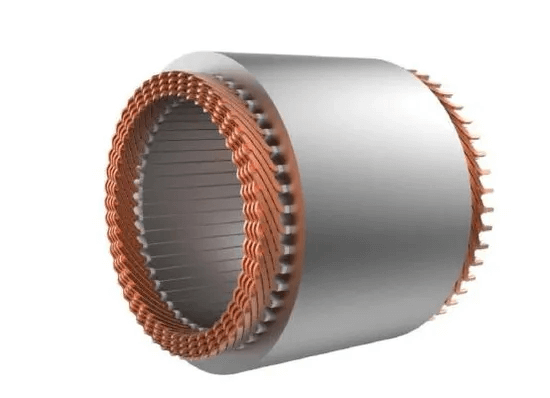

The hairpin motor stator assembly is the core component of flat-wire motor design and represents one of the most complex and challenging elements in EV motor manufacturing. Hairpin stators are highly customized, and once the design is finalized, any change in conductor geometry or dimensions requires new, dedicated tooling, which is costly and offers very limited cross-platform compatibility.

The complete hairpin motor stator manufacturing process typically includes slot insulation insertion, coil forming, pre-insertion, full insertion, end expansion, twisting, end trimming, welding, coating and impregnation, and terminal welding. Compared with conventional round-wire motors, this process is significantly more complex and shows a much higher dependence on automated production equipment.

Among all process steps, coil forming and welding are the most critical and technically demanding operations. They require extremely high precision, tight tolerance control, and stable repeatability, which can only be achieved through specialized, high-end automation equipment designed specifically for high-volume hairpin stator production.

1. Component Manufacturing Stage

The component manufacturing stage includes the following key production processes:

Stator core and rotor core production, including lamination stamping, stacking, and welding

Stator winding processes, such as winding, coil insertion, and varnish impregnation

Housing, front and rear end covers, and gearbox housing manufacturing, involving casting followed by CNC precision machining

Shaft and gear production, including forging and CNC high-precision machining

Rotor assembly, including magnet insertion and mechanical assembly

After completion, all components undergo inspection and quality verification before being transferred to the final assembly workshop for system-level assembly and testing.

2. Final Assembly and Testing Stage

The final assembly and testing stage focuses on system integration and performance validation and typically includes:

Housing casting and CNC machining

End cover casting and CNC machining

Stator assembly and rotor assembly

Assembly of functional modules and wiring harnesses

Performance testing, including electrical, mechanical, and thermal tests

This stage ensures that the drive motor system meets design specifications, reliability requirements, and mass-production quality standards.

Core Technologies

Key enabling technologies in motor assembly and automation include:

Critical dimensional control during stator insertion into the housing

Precise temperature control for the cooling jacket thermal fitting

Safety and compliance performance control of the motor assembly

Robotic flexible gripping (fuzzy grasping) technology for handling complex and variable components

Hairpin Motor Stator Manufacturing Process

The hairpin motor stator assembly process typically includes the following steps:

Slot insulation insertion

Coil forming

Pre-insertion

Full insertion

End expansion

Twisting

End trimming

Welding

Coating and impregnation

Terminal (copper lug) welding

Rotor Production Line Process

The rotor manufacturing process generally follows this sequence:

Magnet insertion into the rotor core

Rotor core overmolding (injection molding)

Thermal curing

Rotor stacking

Dynamic balancing

Rotor magnetization

Surface magnetic flux inspection

Rotor press-fitting

Laser marking

Frequently Asked Questions About Hairpin Motor Manufacturing

Q1: What practical benefits does a hairpin motor offer compared to a conventional round-wire motor?

A: At the system level, hairpin motors deliver higher power density, improved efficiency, and a more compact design.

This enables higher output within the same installation space, or reduced size and weight at equivalent performance, contributing to better vehicle range, energy efficiency, and overall system integration.

Q2: Is hairpin motor technology mature enough for mass production?

A: Yes. Hairpin motors have been successfully adopted in large-scale mass production across mainstream electric vehicle platforms.

With the maturation of key processes such as hairpin forming, insertion, and laser welding, production consistency, yield, and long-term reliability now fully meet automotive mass-production requirements.

Q3: Does adopting hairpin motors significantly increase manufacturing costs?

A: From an initial investment perspective, hairpin motors typically require higher equipment and process costs.

However, when evaluated based on overall system performance, efficiency gains, reduced energy losses, and long-term reliability, the total cost of ownership (TCO) is often more competitive—especially for mid- to high-end electric drive applications.

Q4: How do hairpin motors achieve a higher slot fill factor?

A: Hairpin conductors have a rectangular cross-section, allowing them to be arranged more tightly and uniformly within stator slots.

Compared with round-wire windings, this structure enables precise conductor positioning and layout control, significantly increasing slot fill factor and reducing copper losses.

Q5: Why is the end-winding structure of hairpin motors more complex?

A: Hairpin windings require bending, forming, and welding operations at both ends of the stator.

This results in a highly compact and geometrically complex end-winding area, placing stricter demands on hairpin dimensional consistency, forming accuracy, and welding precision—making end-winding processing a key technical challenge.

Q6: How is welding quality ensured in hairpin motor production?

A: Most hairpin stators utilize laser welding to achieve stable and reliable electrical connections.

By precisely controlling laser energy, focal position, and welding paths, and combining these with in-line inspection systems (such as vision inspection and resistance measurement), both electrical performance and long-term reliability can be effectively ensured.

Q7: What are the key requirements when selecting equipment suppliers for hairpin motor production lines?

A: Beyond individual machine performance, critical evaluation criteria include:

Overall production line engineering and system integration capability

Process stability and cycle-time consistency

Proven project experience in automotive applications

Local service availability and long-term technical support

Hairpin motor projects involve multiple critical processes and therefore place high demands on suppliers’ system-level capabilities.

Q8: How can the reliability of a hairpin motor stator production line be evaluated?

A: Reliability should be assessed based on multiple factors, including:

Verified production references and on-site running projects

Yield rate, cycle time, and OEE performance

Stability of forming and welding processes

Capability for future process upgrades and capacity expansion

True reliability lies not only in machine specifications, but in sustained, stable production performance.

Q9: Is it better to purchase individual machines or a complete hairpin motor production line?

A: For automotive motor applications, turnkey production line solutions are often the preferred choice.

An integrated line ensures consistent process logic, matched cycle times, and unified quality control, helping to shorten project timelines, reduce commissioning risks, and achieve stable mass production more efficiently.

Honest Automation’s Experience in Hairpin Motor Manufacturing

With the increasing adoption of hairpin motors in electric drive systems, manufacturing success depends heavily on stable processes and well-integrated automation solutions.

Honest Automation has accumulated practical experience in hairpin motor production equipment, covering hairpin forming, insertion, end-winding forming, laser welding, and inline testing.

The company provides both standalone process machines and turnkey hairpin stator and motor assembly lines, supporting customers from pilot production to high-volume manufacturing.

Through multiple EV motor projects, Honest Automation has helped global customers improve process stability, yield performance, and scalability, enabling reliable mass production of hairpin motor stators and complete motor assemblies.