In motor manufacturing, stator winding is a critical process that directly affects product performance and reliability.

Issues such as misaligned coils, wire breakage, insulation damage, or uneven tension not only reduce production efficiency but can also lead to serious quality problems, including excessive motor temperature rise, insulation failure, and increased vibration and noise.

To achieve stable production with high yield, systematic optimization is required at both equipment design and process control levels. Based on in-depth R&D and production of automated motor assembly lines, we have identified six key control points to improve stator winding equipment yield.

These points have become widely recognized industry standards and serve as core considerations during equipment selection and acceptance (not all machines may apply—please evaluate according to actual conditions).

(1) Constant Tension Closed-Loop Control: Ensuring Stable Winding Tension

During stator winding, tension fluctuations are a primary cause of uneven coils, inter-layer collapse, or enameled wire breakage.

This issue becomes particularly significant during high-speed winding, as changes in the coil reel diameter can lead to substantial tension variations, affecting overall winding quality.

Key Control Point: An electronic tension controller, combined with tension sensors, can form a closed-loop feedback system that continuously adjusts the output tension, ensuring stable winding throughout the process.

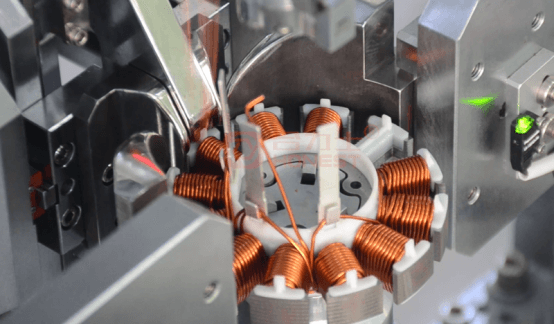

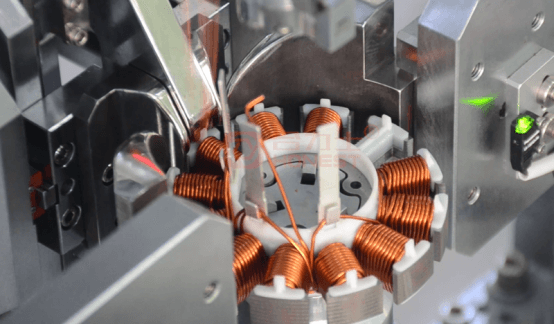

(2) High-Precision Wire Laying Mechanism: Achieving Micron-Level Wire Positioning

Wire laying accuracy directly affects coil neatness, slot fill rate, and end-turn formation quality.

Deviations in wire placement can result in inter-slot errors or excessive stacking, which may compromise motor performance.

Key Control Point: Servo motor drives, combined with precision ball screws or synchronous belt transmission, can achieve micron-level positioning resolution.

The system should also feature the following control to ensure wire-laying speed is strictly synchronized with spindle rotation, preventing wire overlap or missed turns.

(3) Wire Protection Structure: Preserving Enameled Wire Insulation Integrity

If the insulation of enameled wire is damaged, inter-turn short circuits can easily occur during subsequent varnishing or operation, potentially leading to batch-level failures.

Key Control Point: Wire-contact components, such as wire guides, rollers, and pass-through holes, should be made of hard alloy or smooth-coated materials, with edges rounded.

The wire path should be as straight as possible with minimal bending angles to prevent enameled wire from being scratched by metal burrs or sharp edges.

(4) Automatic Wire Break Detection and Stop Protection: Preventing Ineffective Operations

If a wire break is not detected promptly, the machine may continue idle winding, resulting in significant material and labor waste.

Key Control Point: Install wire break sensors along the entire wire path. Once a break is detected, the system should automatically stop, trigger audible and visual alarms, and display the fault information on the HMI for quick troubleshooting and resolution.

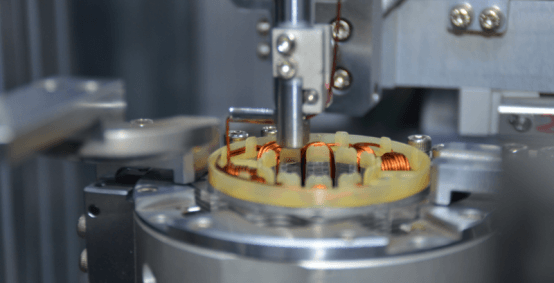

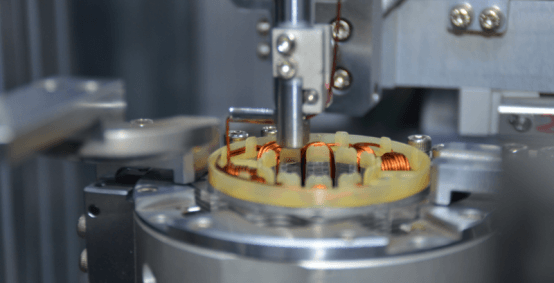

(5) Automatic Wire Loading and Start-Up: Ensuring Accurate First-Turn Placement

In traditional manufacturing, manual wire loading is prone to misalignment or loosening, which is a primary cause of first-turn displacement or inter-slot errors.

Key Control Point: A pneumatic wire-clamping mechanism or vision-assisted positioning system can be configured to automatically guide the wire tip into the designated slot and secure it, ensuring accurate placement of the first turn.

(6) High-Rigidity Molds and Stable Clamping: Ensuring Dynamic Winding Balance

During the winding process, insufficient mold precision or unstable clamping can cause the stator to vibrate or shift at high speeds, leading to disordered wire placement.

Key Control Point: The mold should be manufactured with high-precision machining, and the clamping mechanism can use electric or hydraulic locking with adjustable clamping force to accommodate different slot depths and outer diameters.

For larger stators, additional support structures can be added to enhance overall rigidity, ensuring dynamic balance during winding.

Honest Automation is a high-tech enterprise specializing in the development and integration of intelligent production lines for the motor industry.

We serve industries including new energy vehicles, household appliances, power tools, humanoid robots, medical devices, as well as two-wheelers, three-wheelers, and electric motorcycles, providing full-process motor automation solutions from stator and rotor winding, welding, assembly, to testing.

We understand that a high-performance stator winding machine must not only be capable but also deliver consistent, precise, and durable operation.

Therefore, our equipment design always emphasizes the key control points for minimizing winding defects, helping customers achieve high-quality, high-efficiency, and low-waste motor manufacturing upgrades.

If you are planning or optimizing your motor production line, we invite you to visit Honest Automation for professional process consultation and equipment selection guidance.