What is an Axial Flux Motor?

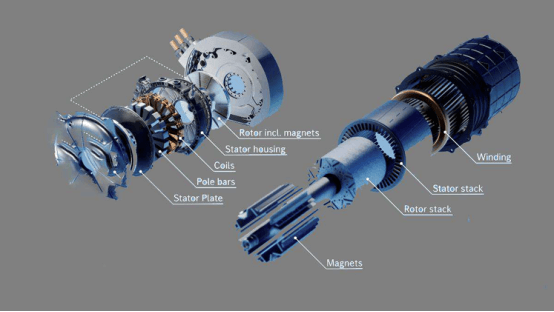

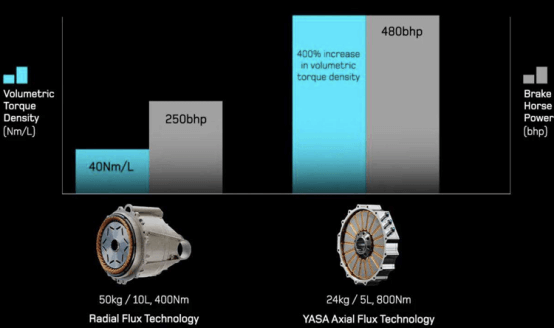

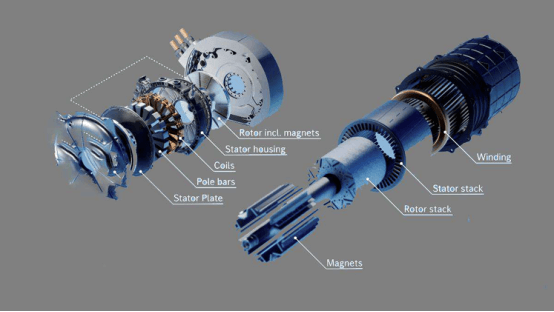

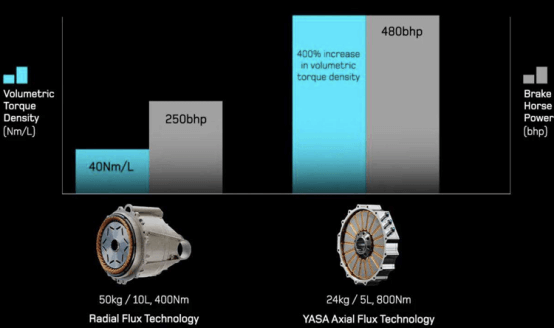

Axial Flux Electric Motor achieves higher power density and greater design flexibility by altering the magnetic flux direction and structural layout, positioning the rotor alongside the stator. Also known as disc motors, axial flux motors are an innovative type of motor with a magnetic flux path distinct from conventional radial flux motors. They feature a planar air gap, where the magnetic field runs parallel to the motor shaft.

The most distinctive structural feature of axial flux motors is that the rotor is located beside the stator, rather than being enclosed within it as in traditional motors. This configuration allows for a significantly larger rotor diameter, resulting in higher torque density and enhanced flexibility in structural design. As a result, axial flux motors are emerging as a key technology for next-generation high-performance drive systems.

How Axial Flux Motors Empower Humanoid Robots

Axial flux motors are particularly well-suited for the leg systems of humanoid robots that require high load-bearing capacity. The leg mechanism of a humanoid robot is responsible for supporting the robot’s entire body weight and maintaining stable locomotion, which places extremely high demands on motor torque output and reliability. In this context, axial flux motors demonstrate remarkable advantages.

For instance, the leg system of the Qinglong humanoid robot adopts axial flux motors, achieving a maximum torque of 396 N·m at the hip and knee joints, with a peak torque density of 200 N·m/kg. This enables the robot to maintain stable walking performance even on complex and uneven terrain.

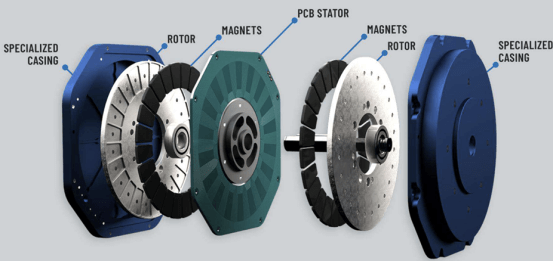

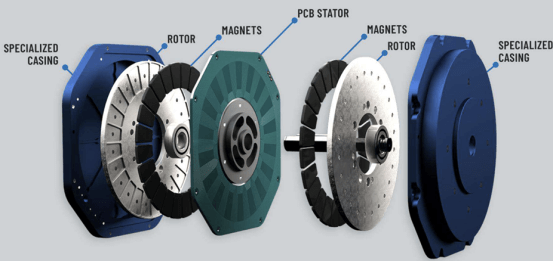

PCB axial flux motors show strong potential for application in humanoid robot dexterous hands. As the most sophisticated actuators in a humanoid robot, dexterous hands are compact yet require a high degree of freedom. This means a large number of motors, sensors, and transmission components must be integrated into a very limited space.

Consequently, the motors used must meet extremely demanding requirements—ultra-compact size, lightweight structure, fast response speed, and high control precision. These characteristics align perfectly with the inherent advantages of axial flux motor technology, making PCB axial flux motors an ideal solution for next-generation robotic hands that require both agility and precision.

Axial flux motors have the potential to achieve lower overall costs compared to traditional motor types. However, manufacturing cost remains one of the major barriers preventing their large-scale commercialization. At present, the production cost of axial flux motors is approximately 20–30% higher than that of conventional radial flux motors with equivalent power output, according to EV Vision.

This cost gap primarily stems from factors such as the specialized materials required, complex manufacturing processes, and the limited maturity of industrial supply chains. Overcoming these challenges will be essential for the widespread adoption of axial flux motor technology in future high-performance applications.

High material costs are one of the primary sources of cost pressure for axial flux motors. Their design requires the use of numerous specialized and expensive high-performance materials, including:

High-temperature permanent magnets – Axial flux motors must use high-grade NdFeB magnets enhanced with costly heavy rare earth elements such as dysprosium (Dy) and terbium (Tb) to maintain magnetic performance under elevated temperatures.

Carbon fiber composites – These materials are widely used in rotor manufacturing for their strength and lightweight properties, but their prices are significantly higher than conventional metals.

Auxiliary materials – Specialized insulating materials, precision bearings, and other supporting components also contribute to higher overall costs compared to traditional motor designs.

Together, these material requirements make axial flux motors inherently more expensive to produce, despite their superior performance potential.

Complex Manufacturing Processes

The demanding precision requirements and relatively low level of automation in axial flux motor production significantly increase manufacturing costs:

High equipment investment – Achieving micrometer-level air gap control requires expensive precision machinery such as high-accuracy CNC machines and laser processing equipment. Additionally, the stator, winding, and rotor each require specialized tooling and dedicated production equipment, leading to high capital expenditure and poor equipment versatility.

High labor costs – Automation levels remain far lower than in conventional motor manufacturing. Many critical processes still rely on skilled manual labor, increasing both production time and labor expenses.

Low yield rates – The complex production workflow and tight precision tolerances result in longer inspection procedures and lower yield rates. Consequently, scrap and rework costs are higher, further driving up overall manufacturing expenses.

These challenges make it difficult to achieve economies of scale, slowing down the industrialization of axial flux motor technology despite its technical advantages.

Limited Industrial Maturity

The axial flux motor industry is still in its early stage of development and has yet to benefit from the economies of scale that reduce costs in more mature sectors:

Small-scale production – Most manufacturers operate on a limited production scale, making it difficult to distribute fixed costs efficiently. Low-volume output also weakens their bargaining power in raw material procurement, leading to higher unit costs.

Immature supply chain – Due to the unique structural design of axial flux motors, many components—such as custom-shaped permanent magnets and non-standard bearings—must be specially manufactured. The limited number of qualified suppliers increases both purchasing costs and lead times.

Lack of standardization and industrial synergy – The absence of unified manufacturing processes and testing standards hinders the formation of an industrial cluster effect. Without collaboration and standardization, it remains difficult to lower overall production and supply chain costs.

As a result, despite their strong performance advantages, axial flux motors still face significant barriers to cost reduction and large-scale commercialization.

Honest Automation provides complete automation solutions for axial flux motor winding production, along with prototype development services for humanoid robot axial flux motors. We have successfully delivered motor manufacturing lines to the world’s most renowned and leading humanoid robot companies, demonstrating our proven expertise and advanced technology in this field.

We warmly welcome enterprises seeking humanoid robot motor assembly or automation solutions to consult with our technical experts for tailored proposals. You are also invited to visit our factory to exchange insights and explore state-of-the-art technologies in humanoid robot manufacturing.