Some details about flat wire motor:

Definition: The flat wire motor is a motor whose sub-winding is made of flat copper wire. And it is also called hairpin motor because the shape of the flat copper is similar to a hairpin.

The classification of flat wire motor:

The first one: classified by product type

1. Concentrated winding flat wire motor: The flat copper wire is wound into a single-tooth winding, and one tooth is installed corresponding to a single-tooth winding. Its characteristic is that the short-span coil ends can effectively reduce the end size, and its process is simpler than the Hairpin motor.

2. Wave winding flat wire motor: Flat copper wire is used to wind the wave winding, which is then embedded in the stator slot. It is characterized by high winding utilization and high efficiency, but the process is complex.

3. Hairpin flat wire motor: The flat copper wire is wound into a hairpin shape, and then the hairpin-shaped copper wire is inserted into the stator slot and welded. Its characteristic is that only one end needs to be welded, so the process is simple and the efficiency is high.

Among the above three types, the hairpin motor is the most widely used flat wire motor technology.

The second one: classified by the number of winding layers

1. The single layer winding: Simple structure, low manufacturing cost, but low efficiency.

2. The double-layer winding: High efficiency, but complex process and high cost.

3. The single-double layer winding: It is based on the single-layer winding and adds an outer winding, collecting the advantages both of the single and double one.

4. Multi-layer winding: It has the highest efficiency, but the most complex process and expensive cost.

The advantages of flat wire motor:

1. High slot fill factor, the motor size is smaller and the weight is lighter and has higher power density.

2. Higher conductivity and higher motor efficiency.

3. Better heat dissipation performance and low motor temperature rise.

4. High temperature and high-pressure resistance, longer motor life.

5. Simple maintenance: The flat wire motor does not require lubrication and adjustment, making maintenance simple and cheaper.

The disadvantages of flat wire motor:

1. The manufacturing process is complex and the cost is high.

2. Skin effect is likely to occur at high speeds, affecting motor performance.

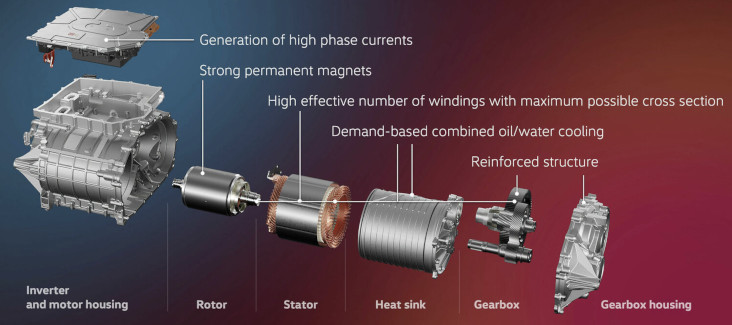

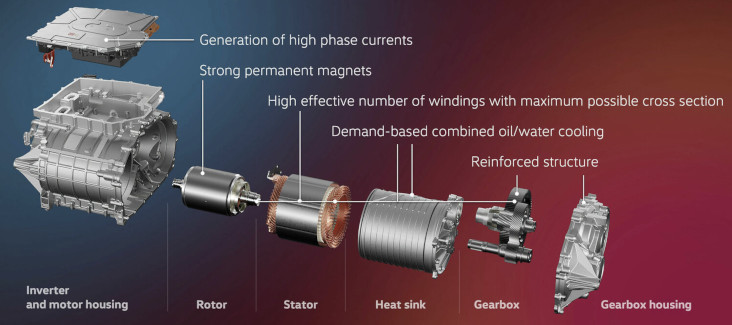

The structure of the flat wire motor:

The structure of the flat wire motor is mainly composed of a stator, a rotor, a bearing, a shell, and other components.

1. Stator: It is the core component of the flat wire motor, and consists of an iron core and winding. The iron core is composed of lamination, which can improve the magnetic field strength and efficiency of the motor. And the winding is made of flat copper wire, which has high conductivity and resistivity, which can reduce the copper loss of the motor and improve efficiency.

2. Rotor: It is another core component of the flat wire motor, consisting of a rotor core and rotor winding. The rotor core is also composed of lamination, which can improve the magnetic field strength and efficiency of the motor. The rotor winding is usually wound with round wire, which can boost the torque density of the rotor.

3. Bearing: It is the supporting part of the flat wire motor, which can prevent the motor from generating vibration and noise during operation.

4. Shell: It is the external protective part of the flat wire motor, which can prevent the motor from being damaged by the external environment.

The structure features of flat wire motor:

1. The winding uses flat copper wire, which has high conductivity and resistivity, and it can reduce the copper consumption of the motor and improve efficiency.

2. The winding structure of the flat wire motor is relatively simple, which can reduce manufacturing costs.

3. The flat wire motor has a high winding utilization, which can improve the efficiency of the motor.

The working principle of the hairpin motor:

Using the electromagnetic principle, the current is applied to the coil to generate magnetic field force, which changes the stroke of the flat wire motor and drives the movement of the mechanical load. Because the flat wire motor uses linear motion, it is more direct and accurate than rotational motion and can achieve very fine position control.