Brushless direct current motor is also abbreviated as BLDC motor, we all know that brushless motor is the future of the electric motors field, and it can be used in every aspect of our lives, such as electric fans, hair dryers, and electric vehicles, and so on.

Some introductions about BLDC Motor are as follows.

Definition:

The brushless motor refers to a motor without brushes and commutator, it is the most commonly used motor besides brushed motors. The brushless DC motor does not use mechanical brush devices. It uses square wave self-controlled permanent magnet synchronous motors and Hall sensors to replace carbon brush commutators. Regarding performance, BLDC has great advantages over the ordinary traditional DC motor.

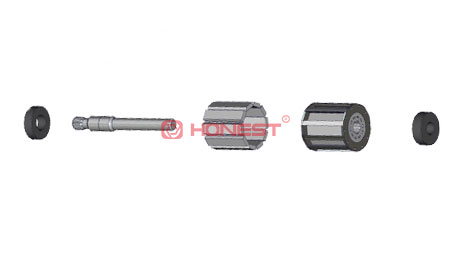

Structure:

The brushless motor mainly consists of four parts: a stator, a rotor, a power supply, and a controller.

Working Principle:

The brushless motor is a typical mechatronics product, consisting of a motor body and a driver. The driver is composed of power electronic devices integrated circuits and so on. Its functions are to accept the start, stop, and braking signals of the motor to control the start, stop, and braking of the motor; accept position sensor signals and forward and reverse rotation signals to control the on and off power of the inverter bridge to generate continuous torque; accept speed instructions and speed feedback signals to control and adjust the speed; provide protection and display, and so on.

Advantages:

1. It can replace DC motor speed regulation, variable-frequency drive + variable-frequency motor speed regulation, and asynchronous motor + reducer speed control;

2. It has the advantages of traditional DC motors while eliminating the carbon brush and slip ring structures;

3. It can operate at low speed and high power, and can directly drive large loads without the need for a reducer;

4. Small size, light weight and high output;

5. Excellent torque characteristics, good medium and low-speed torque performance, large starting torque and small starting current;

6. Stepless speed regulation, wide speed regulation range and strong overload capability;

7. Soft start and stop, good braking characteristics can eliminate the need for the original mechanical braking or electromagnetic braking device;

8. High efficiency. The motor itself has no excitation loss and carbon brush loss, eliminating multi-stage deceleration losses. The comprehensive power saving rate can reach 20%~60%;

9. High reliability, good stability, strong adaptability, and simple repair and maintenance;

10. Resistant to bumps and vibrations, low noise, small vibration, smooth operation and long life;

11. It does not produce sparks and is especially suitable for explosive places, with explosion-proof types;

12. Trapezoidal wave magnetic field motor and sine wave magnetic field motor can be selected as needed;

13. Electronic commutation replaces traditional mechanical commutation, with reliable performance, low failure rate and super long life.

Disadvantages:

1. There is a slight vibration when starting at low speed. If the speed and the commutation frequency increase, the vibration will not be felt;

2. The price is expensive and the requirements for the controller are high;

3. It is easy to form resonance. Resonance is easy to form when the vibration frequency of the brushless motor is the same as or close to the vibration frequency of the frame or plastic parts, which will cause increased vibration and noise of the motor, and even damage the motor.

Application:

The brushless motor is widely used: not only can it be used in fans, water pumps, hair dryers, and so on, but it can also be used in oil pump control, electric controllers, engine control, and the rest in the automotive industry.

Precautions:

In terms of selection, the main parameters that need to be referenced when selecting a brushless DC motor are the following:

1. Maximum torque: It can be obtained by adding the load torque, moment of inertia and friction. In addition, some additional factors that affect the maximum torque, such as the resistance of the air gap.

2. Square modulus: It can be approximately considered to be the continuous output torque required for practical applications, which is determined by many factors: maximum torque, load torque, moment of inertia, acceleration and deceleration running time, and the rest.

3. Speed: This is the speed required by the application, and it can determine the speed requirement of the motor according to the motor’s speed trapezoidal curve. Usually, a 10% margin should be left in the calculation.

In terms of daily maintenance:

1. Before disassembly, blow the motor surface dust with compressed air and wipe the surface dirt clean.

2. Select the working place where the motor is disassembled and clean up the on-site environment.

3. Be familiar with the structural characteristics and maintenance technical requirements of the motor.

4. Prepare the tools (including special tools) and equipment required for disassembly.

5. To further understand the defects in the operation of the motor, if possible, an inspection test can be done before disassembly. To this end, put the motor on load for test rotation, check the temperature, sound, vibration, etc. of each part of the motor in detail, and test the voltage, current, speed, and so on, then disconnect the load, conduct a separate no-load inspection test, and measure the no-load test. Record the load current and no-load loss.

6. Cut off the power supply, remove the external wiring of the motor, and make records.

7. Use a megohmmeter with appropriate voltage to test the motor insulation resistance. To compare with the insulation resistance value measured during the last maintenance to determine the motor insulation change trend and insulation status, the insulation resistance values measured at different temperatures should be converted to the same temperature, generally converted to 75°C.

8. Test the absorption ratio K. When the absorption ratio is greater than 1.33, it indicates that the motor insulation has never been affected by moisture or the degree of moisture exposure is not severe. To compare with previous data, the absorption ratio measured at any temperature must also be converted to the same temperature.

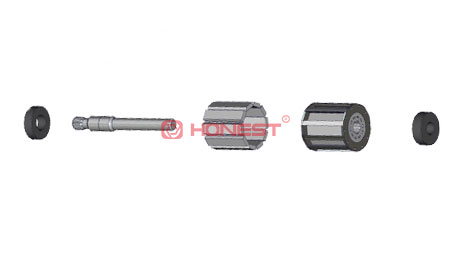

As a company, that engages in the research and development, production and sales of intelligent equipment, and provides digital and intelligent overall solutions for leading companies in the field of new energy vehicles, HONEST Automation has sophisticated and complete equipment and production lines for the production of brushless motor parts, such as brushless motor rotor assembly line, brushless motor stator production line, and the rest.

(The picture below shows our BLDC motor assembly line)

Please feel free to contact us if you have any needs or questions about our equipment or production lines.

Tel/Wechat/WhatsApp: +8618923732990

E-mail: sales@honest-hls.com