Traditional automotive suspension systems consist of components such as elastic elements (springs), shock absorbers, and guiding mechanisms. These components connect the vehicle body and chassis to the wheels, transmitting forces and torque while also dampening road-induced shocks.

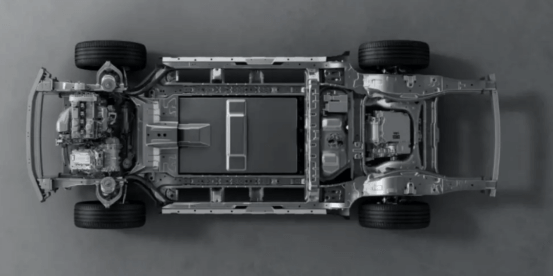

In contrast, the air suspension system used in electric vehicles (EVs) replaces traditional coil or leaf springs with air springs (airbags) that allow for adjustable air pressure. These air springs serve as the suspension’s elastic element, enabling adaptive ride height and improved ride comfort. An EV air suspension system typically comprises several key components: an air compressor, air reservoir, height control valves, various sensors, and an electronic control unit (ECU) that intelligently manages the system's operation.

Air Suspension: Built on a Legacy of Innovation

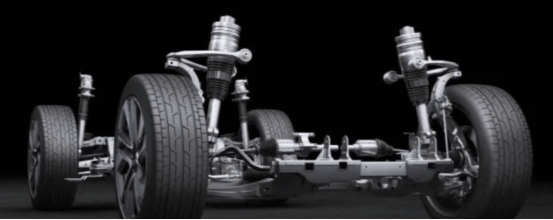

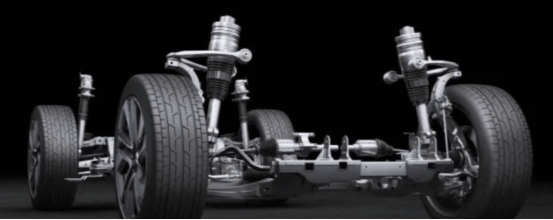

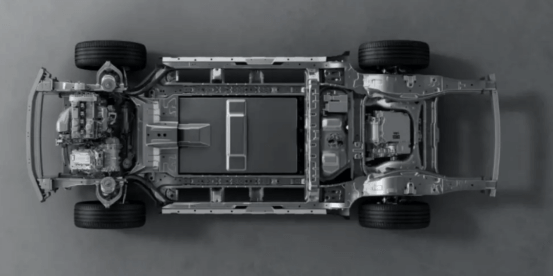

Simply put, the suspension system is the set of components that connects a vehicle’s wheels to its body. It serves two main purposes: absorbing shocks and supporting the vehicle’s weight. The core components typically include three elements: control arms (or linkages), springs, and shock absorbers.

Control arms guide the motion and angle of the wheels. Common suspension layouts include double wishbone, single-arm, torsion beam, and multi-link systems.

Springs support the vehicle’s weight and help smooth out bumps and uneven road surfaces. Types of springs include coil springs, leaf springs, torsion bars, and air springs.

Shock absorbers (or dampers) are responsible for minimizing the oscillation of the springs. They come in various types such as hydraulic, gas-charged, and electromagnetic.

As previously introduced, an air suspension system replaces traditional springs with air springs and enables dynamic adjustment of ride height and comfort. Here's how it generally works:

Sensors continuously monitor the vehicle’s ride height and send data to the ECU (Electronic Control Unit). The ECU processes the data through pre-set algorithms and sends commands to the air supply system. The air compressor draws in ambient air, removes moisture and impurities through a dryer, and then stores the clean, compressed air in a reservoir. This air is then distributed via solenoid valves to each air spring at the wheels, allowing real-time adjustment of suspension stiffness and damping.

Due to its sophisticated design and electronically controlled functionality, many newcomers to the electric vehicle (EV) industry mistakenly believe that air suspension is a modern invention. In reality, the technology has a history spanning over a century.

As early as 1914, the Owen Magnetic from the United States became the first car equipped with an air suspension system.

In 1929, Czech manufacturer TATRA applied air suspension to its heavy-duty trucks.

By the 1950s and 1960s, air suspension was already being widely adopted in urban buses and coaches across the U.S.

Between 1960 and 1980, significant improvements were made in air spring designs, pneumatic components, and system reliability.

In 1992, the launch of the Range Rover with factory-equipped air suspension marked the beginning of its popularity in passenger vehicles.

By the late 1990s, air suspension had achieved widespread adoption across Europe and North America, with around 95% of buses, 80% of heavy trucks, and 40% of trailers utilizing the system.

In China, air suspension technology has a shorter yet eventful history, marked by periods of progress and setbacks.

In 1957, the Changchun Automotive Research Institute collaborated with the Beijing Rubber Industry Research and Design Institute to develop China’s first heavy-duty truck equipped with air springs.

From 1980 to 1987, the same institute went on to design multiple air suspension systems for buses and trolleybuses in partnership with companies like Wuhan Bus Factory and Shenyang Trolleybus Company. However, these early systems faced several challenges, including short airbag fatigue life, air leakage in height control valves, and slow dynamic response.

During the 1990s to early 2000s, as China's highway infrastructure rapidly expanded, domestic manufacturers began importing air suspension systems, chassis components, and even complete buses with integrated air suspension from abroad.

From the early 2000s to 2018, the commercial vehicle standardization framework in China gradually matured, paving the way for broader adoption of air suspension. At the same time, market demand accelerated the localization process, with major companies like CNHTC (China National Heavy Duty Truck Group), Dongfeng Automotive Suspension Spring Co., Ltd., and Shanghai Komman Vehicle Component Systems Co., Ltd. investing in R&D and production of domestic air suspension systems.

Since 2018, a growing number of Chinese-branded passenger vehicles have been equipped with air suspension. With advancements in local manufacturing and increased competition, the cost of air suspension-equipped vehicles has dropped significantly, making the technology more accessible to the mass market.

Main Parts of the Air Suspension System

1. Air Springs (Airbags)

Air springs are the core component of an air suspension system. Typically made from high-strength rubber or composite materials, these airbags are filled with compressible air. By adjusting the internal air pressure, the system can modify the spring stiffness, allowing the vehicle to change its ride height and tune suspension softness or firmness as needed.

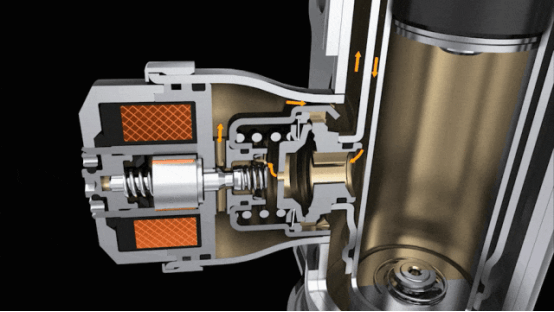

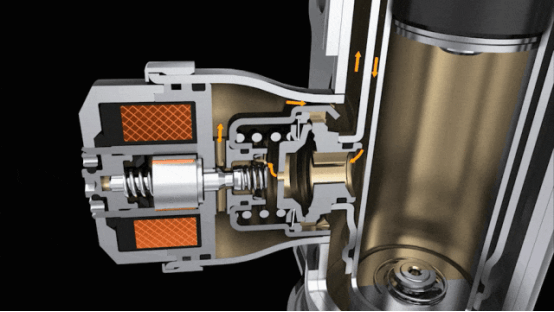

2. Air Compressor

The air compressor is responsible for supplying pressurized air to the system. It is usually powered by an electric motor and can increase or release pressure based on commands from the control unit. The compressor draws in ambient air, compresses it, and stores it in an air reservoir, which then supplies air to the springs for inflation or pressure adjustment.

3. Air Reservoir

The air reservoir stores compressed air to provide a stable air supply for the system. It is equipped with pressure sensors and safety valves to maintain pressure within safe limits. When the pressure exceeds the set threshold, the safety valve releases excess air to ensure system safety.

4. Height Control Valves

Height control valves—including solenoid valves and proportional valves—precisely regulate the inflation and deflation of the air springs according to commands from the Electronic Control Unit (ECU). These valves respond rapidly to ensure smooth and accurate real-time adjustment of the vehicle’s ride height.

5. Shock Absorbers

The air suspension system typically uses adjustable damping shock absorbers, such as Continuously Damping Control (CDC) shock absorbers. These can dynamically vary the damping force by controlling the flow rate of hydraulic fluid inside, adapting suspension firmness based on vehicle status and driving modes.

4. Sensors

The system includes various sensors such as ride height sensors, accelerometers, tilt angle sensors, and vehicle speed sensors. These sensors continuously monitor the vehicle’s status—such as body height, speed, acceleration, and lateral tilt—and provide real-time feedback to the ECU for suspension adjustments.

5. Electronic Control Unit (ECU)

The ECU acts as the “brain” of the air suspension system. It receives sensor data, processes control logic, and sends commands to actuators. Based on pre-programmed algorithms and real-time vehicle conditions, the ECU determines parameters like air spring pressure, shock absorber damping, and ride height to ensure optimal suspension performance under varying driving scenarios.

6. Pipelines and Connectors

A complete air suspension system also requires a network of high-pressure air hoses, connectors, quick couplings, and sealing components. These ensure efficient and airtight air flow throughout the system.

9. Suspension Components

In addition to the air suspension-specific parts mentioned earlier, the system also includes traditional suspension components such as control arms, linkages, tie rods, struts, and bearings. These structural elements collectively form the mechanical framework of the air suspension system, supporting and guiding wheel movement.

The primary difference between air suspension and traditional suspension lies in the upgrade of the elastic elements and the addition of electronic control systems. Among these, the air springs and electronically controlled shock absorbers are the core components defining air suspension technology.

Advantages of Air Suspension

1. Ride Comfort

Air suspension effectively absorbs road shocks, naturally providing a smooth and comfortable ride experience. This is especially beneficial for electric vehicles (EVs), which prioritize quietness and superior comfort.

2. Handling Stability

As mentioned earlier, adjustable ride height and adaptive damping offer significant value. These features help optimize vehicle posture, enhance high-speed stability, and improve grip and driver confidence during cornering.

3. Off-Road Capability

Raising the vehicle’s ride height improves the EV’s ability to tackle challenging terrains such as off-road trails, curbs, or flooded roads.

4. Battery Protection

For EVs, air suspension maintains a consistent ride height, reducing the severe vibrations caused by uneven roads. This helps protect the battery pack and its internal structure, thereby extending battery life.

5. Energy Efficiency

By optimizing air spring pressure and shock absorber damping, air suspension reduces rolling resistance during driving, which can contribute to improved driving range for electric vehicles.

Market Status and Trends

Technological Development Trends

Intelligent Integration:

Air suspension systems are becoming deeply integrated with the vehicle’s electronic architecture, enabling more precise ride height control, adaptive damping adjustment, active anti-roll functions, and seamless coordination with autonomous driving systems.

Lightweight Design:

By leveraging new materials and structural innovations, manufacturers aim to reduce the weight of air suspension systems to meet growing demands for energy efficiency and emission reduction.

Modularization and Standardization:

Emphasis is being placed on increasing the modularity and interchangeability of air suspension components. This helps reduce manufacturing costs and shortens development cycles.

Sustainability and Environmental Focus:

There is a growing focus on improving the environmental performance of air suspension systems throughout their lifecycle. This includes using recyclable materials, enhancing energy efficiency, and minimizing noise emissions.

Impact of Policies and Regulations

Government Policies and Incentives:

Stricter regulations on vehicle emissions, energy consumption, and safety, along with government incentives for new energy vehicles (NEVs), are driving positive momentum in the air suspension industry.

Standards and Compliance Requirements:

National and international standards related to vehicle safety, environmental impact, and performance impose specific design, manufacturing, and testing requirements for air suspension systems, directly influencing the industry’s technical roadmap and future development direction.

At HONEST Automation, we offer comprehensive solutions for automotive air suspension motor assembly. From motor prototyping to semi-automatic lines and fully automated assembly systems, we support every stage of your production process. Our team of technical experts is ready to help you design a customized solution tailored to your specific requirements.

Contact us today to discuss how we can accelerate your air suspension motor production with precision and efficiency.