Introduction to Coil Winding Machines

A coil winding machine is an indispensable piece of coil winding equipment used across industries to manufacture precise electromagnetic coils for motors, transformers, solenoids, and other electrical components. These machines automate the process of wrapping conductive wire—typically copper or aluminum—around a core, ensuring uniformity and efficiency in production.

With advancements in coil winding technology, modern machines now offer programmable automation, real-time monitoring, and high-speed winding capabilities, making them crucial for industries requiring mass production of high-quality coils.

Different Types of Coil Winding Machines

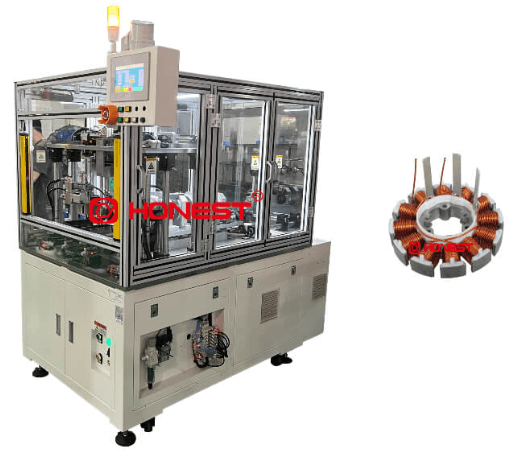

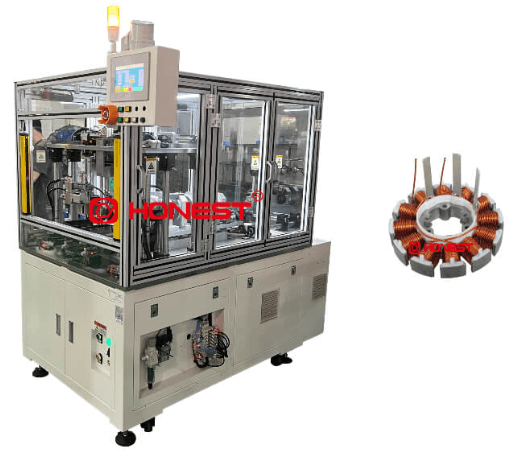

1. Stator Coil Winding Machine

These machines specialize in winding stator coils for electric motors and generators. They ensure precise layering and tension control to meet strict electrical performance standards.

2. Rotor Coil Winding Machine

Optimized for rotor applications, these machines handle high-speed winding while maintaining accuracy in wire placement, crucial for motor efficiency.

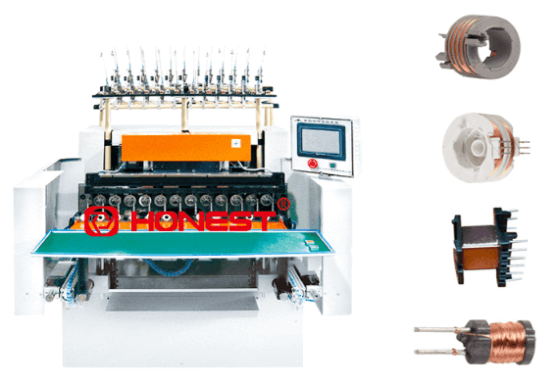

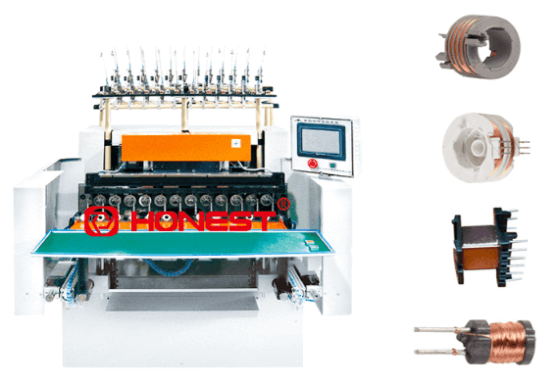

3. Automatic Coil Winding Machine

Fully programmable and ideal for large-scale production, these machines reduce labor costs and improve consistency with features like auto wire threading and tension control.

4. Motor Coil Winding Machine

Designed specifically for electric motor manufacturing, these machines support various winding patterns, including concentrated and distributed winding techniques.

5. Custom Coil Winding Machinery

Some manufacturers offer tailored solutions for specialized industries, such as aerospace or medical devices, where unique coil specifications are required.

How Does a Coil Winding Machine Work?

Step 1: Setup & Preparation

Load the wire spool and core (bobbin, stator, or rotor) into the machine.

Adjust guides and tensioners to prevent wire breakage or slippage.

Step 2: Programming & Calibration

Input winding parameters (number of turns, wire speed, layering pattern).

Modern automatic coil winding machines allow digital programming for repeatable precision.

Step 3: Winding Process

The machine rotates the core while the wire feeder moves in a controlled pattern.

Sensors monitor tension and alignment to ensure consistency.

Step 4: Finishing & Inspection

Once winding is complete, the coil is removed and inspected for defects.

Some advanced machines include automated testing for resistance and insulation quality.

Key Benefits of Using a Coil Winding Machine

Precision & Consistency – Eliminates human error, ensuring uniform coil quality.

High-Speed Production – Automated machines can wind hundreds of coils per hour.

Cost Efficiency – Reduces material waste and labor expenses.

Flexibility – Adjustable settings allow for different wire gauges and winding patterns.

Durability – Industrial-grade coil winding machinery ensures long-term reliability.

Choosing the Right Coil Winding Machine Manufacturer

When selecting a coil winding machine manufacturer, consider:

Machine Specifications – Does it support your required wire gauge, speed, and winding patterns?

Automation Level – Semi-automatic vs. fully automatic models.

After-Sales Support – Availability of maintenance, training, and spare parts.

Coil Winding Machine Price – Balance cost with features and long-term ROI.

Top manufacturers often provide customized solutions, so discuss your specific needs before purchasing.

Future Trends in Coil Winding Technology

AI & Machine Learning – Predictive maintenance and adaptive winding adjustments.

IoT Integration – Remote monitoring and real-time diagnostics.

Energy-Efficient Designs – Lower power consumption without compromising speed.

Hybrid Winding Systems – Combining traditional and additive manufacturing techniques.

Whether you need a stator coil winding machine for electric motors or a fully automatic coil winding machine for high-volume production, investing in the right coil winding equipment is crucial for efficiency and product quality.

For the best coil winding machine price and advanced coil winding technology, consult leading manufacturers to find a solution tailored to your industry needs.

Need expert advice? Contact a trusted coil winder machine supplier today!

HONEST Automation - Your Trusted Partner in Advanced Coil Winding Solutions

With 19+ years of expertise, HONEST Automation specializes in manufacturing high-performance coil winding machines, including stator, rotor, semi-automatic, and fully automatic models. Our equipment serves diverse industries such as automotive (EV), electric tools, robotics, medical devices, 3C electronics, and industrial automation, delivering precision, efficiency, and reliability. We offer custom-engineered solutions, smart automation integration, and global support to meet unique production needs.

Get a free consultation today! Contact us for tailored winding solutions, competitive pricing, and expert support to optimize your manufacturing process.

Innovating coil winding technology since 2007, Powering your production excellence.

Tel/Wechat/WhatsApp: +8618923732990

E-mail: sales@honest-hls.com