An Anti-lock braking system (ABS) is an automated system that uses threshold and cadence braking principles.

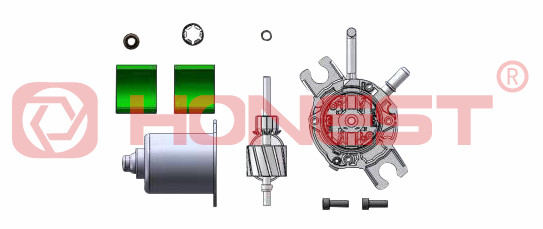

The components of Anti-lock Braking System

An anti-lock braking system has four main components: wheel speed sensors, valves, pumps, and controllers.

A. Speed Sensors: The speed sensor is used to determine the acceleration or deceleration of the wheel;

B. Valves: There is a valve in the brake line of each brake, which is controlled by the anti-lock braking system;

C. Pump: The pump in the ABS is used to restore pressure to the hydraulic brakes after the valves relieve pressure;

D. Controller: The controller is an ECU-type device in the car that receives information from each wheel speed sensor.

The Control Strategies of Anti-lock Braking System

ABS is usually divided into three control strategies: single wheel control, selection low control, and selection high control. They determine how to distribute the braking force to each wheel during the braking process to optimize the braking of the vehicle's dynamic performance and stability.

A. Single Wheel Control

For the vehicle to achieve maximum braking strength, it is necessary to ensure that each wheel makes maximum use of the available adhesion coefficient. An independent control strategy for each wheel can achieve this goal. Therefore, each wheel has a set of sensors for signal measurement and parameter calculation, and has its brake line to achieve independent control of the brake pressure of each wheel.

B. Selection Low Control

The selection low control refers to applying brake pressure control to the wheels on both sides of the same axle at the same time, and the size is determined by the wheel on the side with the lower adhesion coefficient. The selection control strategy can be accomplished through sensors mounted on each wheel or the differential drive gear. Using a selection low control strategy can achieve greater cornering lateral force and ensure vehicle stability.

C. Selection High Control

Selection high control determines the braking pressure of the wheels on both sides of the axle by the wheel on the road with a high adhesion coefficient, so each wheel needs to be equipped with a sensor.

The Working Principles of Anti-lock Braking System

ABS involves a series of complex electronic and hydraulic control processes, and its core goal is to prevent wheel locking during emergency braking, thereby maintaining the vehicle’s handling and braking efficiency. The following is the detailed working principle of the ABS:

A. Wheel Speed Monitoring: ABS monitors the wheel speed in real-time through the wheel speed sensor installed on each wheel;

B. Control Unit Analysis: The ABS control unit receives data from the wheel speed sensor and calculates the difference between the actual wheel speed and the theoretical speed to determine whether the wheel is about to lock;

C. Brake Pressure Adjustment: When it is detected that the wheel is about to lock, the control unit will instruct the hydraulic control unit to adjust the brake pressure to prevent locking by increasing or decreasing the braking pressure on the wheel;

D. Cyclic Operation: ABS will continuously monitor and adjust the braking pressure. The process may be repeated multiple times per second during emergency braking to ensure that the wheels remain in optimal braking condition.

The Technical Difficulties of Anti-lock Braking System

A. Precise Slip Rate Control: The slip rate control needs to be very precise to ensure that the wheels will not lock and the braking distance will not be affected;

B. Quick Response: The ABS needs to respond to the wheel slip state and adjust the braking pressure in a short time, which places higher requirements on the response speed of the system’s electronic control unit and hydraulic actuator;

C. Complex Algorithms: The control unit needs to run complex algorithms to analyze and process data from multiple sensors in real time and make precise control decisions;

D. System Integration: Integrating ABS with other vehicle safety systems to achieve optimal vehicle stability and safety is a big challenge in actual design.

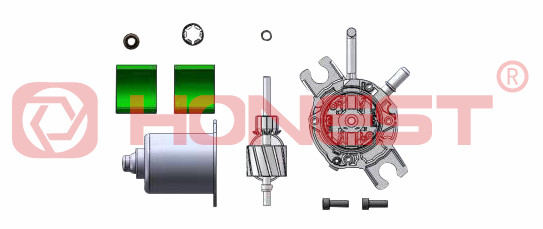

The Advantages of ABS Brake Motor Assembly Line of HONEST

A. Specifically designed for automotive motor and engine systems to ensure optimal compatibility and performance;

B. Integrate advanced QR code printing, automatic labeling, and rapid code scanning technology to achieve seamless connection of information;

C. Adopt a full-process data collection system to ensure monitoring, analysis, and storage during the production process, and improve transparency and traceability;

D. Highly flexible design combined with automation technology improves the adaptability and efficiency of the production line;

E. Streamline the operation process, the entire production line requires only two operators to be responsible for loading and unloading materials;

F. Provide non-standardized customized services to meet customers’ unique production needs and personalized solutions.

If you need additional details or inquire about equipment customization solutions, please feel free to contact us.