The electric pump motor is a pivotal technology in the EV sector, playing an essential role in the thermal management system. The article delves into the intricate structure, operational principles, design characteristics, technical challenges, and future development trajectories of EV electric pump motors.

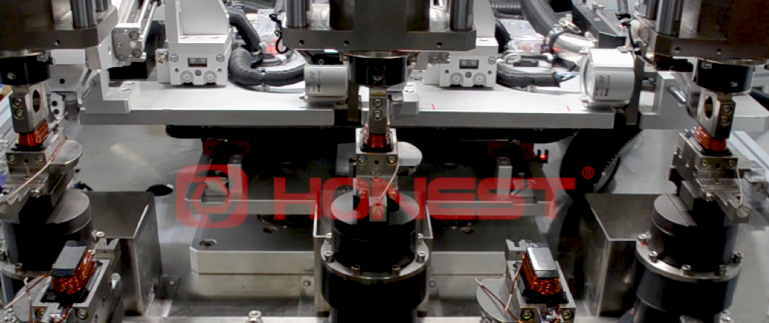

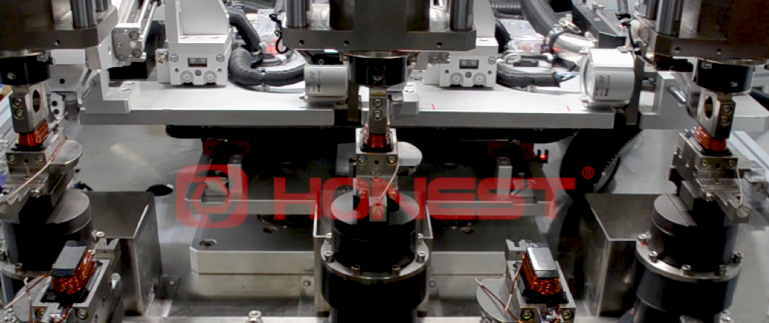

The Structure of the Electric Pump Motor

Electric pump motors in EVs usually consist of the following main parts:

A. Electric Motor: It is the heart of the electric pump motor and is responsible for converting electrical energy into rotational motion. The choice between direct current or alternating current motors is dictated by the vehicle’s design and performance requirements;

B. Pump Motor: Housing an impeller and casing, the pump body facilitates the rotation of the impeller, which, driven by the electric motor, generates pressure to propel liquids through the system;

C. Control System: Electric pump motors are usually equipped with an electronic control unit (ECU), which is used to receive signals from vehicle sensors, such as temperature, pressure, and so on, and adjust the speed of the motor based on these signals to meet different working needs;

D. Sensors and Feedback Devices: To ensure the efficient operation of the pump motor, there are usually feedback devices such as temperature sensors and pressure sensors to monitor the system status in real-time and provide them to the ECU for adjustment.

The Working Principle of the Electric Pump Motor

In electric vehicles, electric pump motors are mainly used to drive coolant circulation to keep the temperature of batteries, motors, and power electronics within the optimal operating range. Electric pump motors usually consist of an electric motor and a pump body. The electric motor receives DC or AC power from the vehicle battery, converts it into rotational motion, and then drives the impeller in the pump body to rotate. The rotation of the impeller creates pressure that pushes the coolant through the vehicle’s cooling system, which includes the battery pack, motor, power electronics, and radiator.

The Design Features of Electric Pump Motor

The design of electric pump motors for electric vehicles needs to take into account compactness, efficiency, reliability, and cost. The following are some of the key design features:

A. Compactness: Electric vehicles have limited space, so electric pump motors need to be designed as small as possible to fit within the vehicle’s space layout;

B. High Efficiency: To maximize the driving range of electric vehicles, electric pump motors need to have a high energy efficiency ratio and reduce energy loss;

C. Reliability: Electric pump motors must maintain stable operation in extreme temperatures and vibration environments to ensure cooling system reliability;

D. Cost-effectiveness: The manufacturing cost of electric vehicles directly affects its market competitiveness, so the design and manufacturing costs of electric pump motors need to be controlled within a reasonable range.

The Technical Challenges of Electric Pump Motor

Electric pump motors in EVs face a series of technical challenges:

A. Thermal management: Batteries and motors generate heat when operating, and electric pump motors need to manage this heat effectively to prevent overheating;

B. Noise Control: The noise generated by the electric pump motor during operation needs to be controlled at a low level to improve driving comfort;

C. Durability: Electric pump motors need to operate stably for a long time under various working conditions, including high and low temperatures, high humidity, salt spray, and other harsh environments;

D. Integration: to simplify system design and reduce costs, electric pump motors often need to be integrated with other systems.

The Future Development Trends of Electric Pump Motor

With the continuous advancement of electric vehicle technology, electric pump motors will also develop in a more efficient, smarter, and more environmentally friendly direction:

A. High Efficiency: By using new materials and optimized designs, future electric pump motors will have higher energy efficiency ratios;

B. Intelligent Control: The electric pump motor will be more closely integrated with the vehicle’s intelligent control system, enabling more precise temperature management;

C. Environmentally Friendly Materials: To reduce environmental impact, the electric pump motor will use more recyclable and environmentally friendly materials;

D. Modular Design: The modular design will make the electric pump motor easier to maintain and replace, reducing the maintenance cost of the entire vehicle.

The electric vehicle’s electric pump motor is a critical component in ensuring vehicle performance and safety. As the electric vehicle market grows rapidly, so does the technology of electric pump motors.

For any further inquiries or requirements regarding electric pump motor equipment, please don’t hesitate to reach out. HONEST Automation eagerly anticipates the opportunity to assist you.