HONEST Intelligent as a professional supplier of automated production lines for electronic oil pumps, has been deeply engaged in the industry for over a decade. We continuously innovate to provide efficient and high-quality production equipment solutions for electronic oil pumps worldwide. Our production line not only reflects technological innovation but also guarantees production efficiency and product quality.

Types and Features of Electronic Oil Pumps

Electronic oil pumps are typically divided into two categories: gear-type and rotor-type oil pumps. Gear-type oil pumps are known for their simple structure and reliable operation, while rotor-type oil pumps are favored for their compact structure, high oil suction vacuum, and large oil pumping capacity. These characteristics make electronic oil pumps increasingly important in modern automobiles.

The Importance and Functions of Electronic Oil Pumps

As a core component of the lubrication and cooling system in new energy vehicles, electronic oil pumps are ideal choices for new energy vehicles due to their high efficiency, low energy consumption, and high reliability. Driven by electric motors, they provide a precise oil supply, ensuring sufficient lubrication and cooling for key components such as engines, transmissions, and electric drive systems under various operating conditions. This technology not only improves the performance and reliability of vehicles but also supports advanced functions such as idle start-stop, hybrid power drive, automatic transmission, and electric drive systems, significantly enhancing the fuel efficiency and driving experience of the vehicle.

With the continuous advancement of technology and the increase in market demand, electronic oil pumps will play an increasingly important role in the future automotive industry.

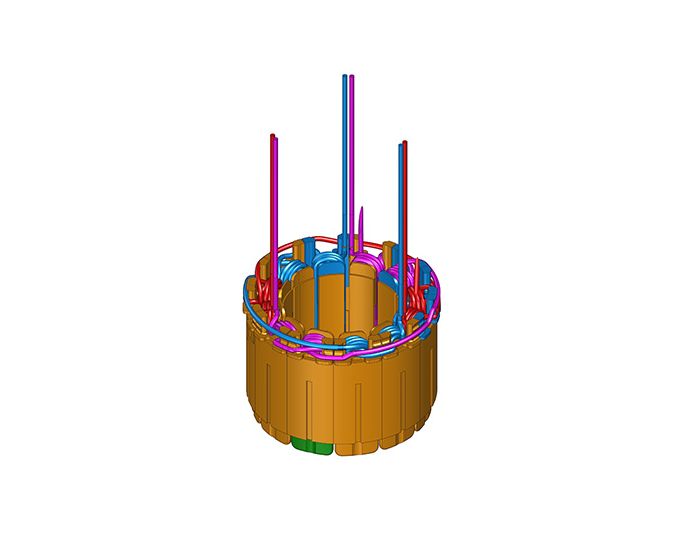

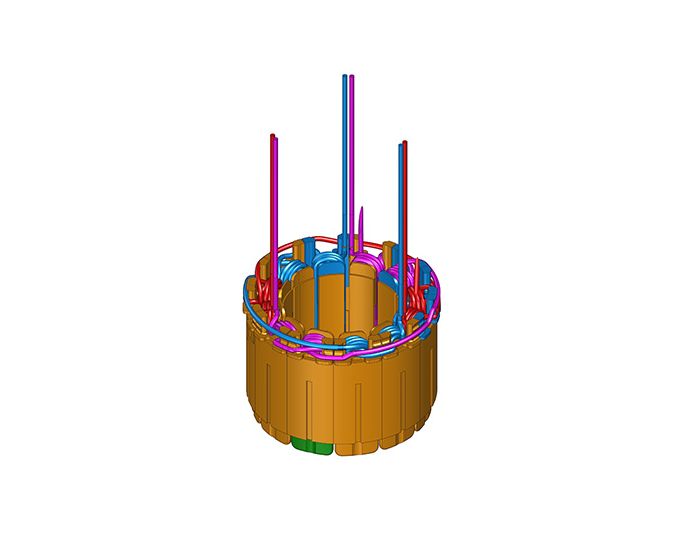

HONEST Intelligent’s Electronic Oil Pump Automated Production Line

HONEST Intelligent’s electronic oil pump automated production line is capable of co-producing multiple types of oil pump stator components through means such as die change. Moreover, we have reserved space for additional equipment in the layout, which facilitates customers' increasing equipment, accelerating production rhythm, and improving production efficiency.

Process Flow: Frame Assembly → Coil Winding → Laser Paint Stripping → Rounding & Wire Straightening → Laser Welding → Stator Performance Testing → Laser Marking

Reasons for Choosing HONEST Intelligent’s Electronic Oil Pump Automated Production Line:

Piercing Insert Terminals: HONEST Intelligent adopts an efficient piercing insert terminal technology, which achieves conductivity between terminals and copper wires by piercing the copper wire enamel. This technology not only has the advantages of no need for paint stripping, preventing oxidation, and no false welding but also saves on processes and production costs.

Comprehensive Traceability System: HONEST Intelligent’s automated production line is equipped with an advanced traceability system to ensure accurate traceability of components. Through laser scanning technology, we can achieve 100% traceability of all components, from the source to the finished product, with every step clearly traceable. The product assembly is marked with a QR code, including the production date and unique traceability number, with the shipping box code bound to the product, ensuring traceability and transparency at every stage, greatly enhancing product quality control and customer trust.

High-precision Sensors and Vision Inspection System: HONEST Intelligent understands the importance of product and quality, hence equipped with high-precision sensors and vision inspection systems. These systems can monitor key parameters in the production process in real time, ensuring precise control and quality inspection at every production stage, thereby improving the overall consistency and reliability of the product.

Complete Data Recording and Query: Our electronic oil pump automated production line has the capability to record and query all collected data. This means that customers can easily obtain all key data in the production process, grasp production dynamics, facilitate analysis and optimization of the production process, and improve production efficiency and product quality.

Intelligent Misoperation and Status Prompting: The equipment prompts various misoperations and bad statuses in real time, ensuring the stability and safety of the production process. This not only reduces production interruptions caused by operational errors but also improves the efficiency of the production line operation.

Ergonomic Design: Our equipment is designed according to ergonomics, making operations simple and easy to learn. This not only reduces the training time for operators but also reduces labor intensity and improves production efficiency.

Data Management Features: Equipped with data backup, migration, and cleaning functions, ensuring the security and integrity of production data. This provides great convenience for long-term management and maintenance, ensuring the reliability and traceability of data.

Exception Alarm and Location Prompting: Display exception alarms on the screen and prompt the location of exceptions, helping operators quickly locate and solve problems. This intelligent prompt system greatly reduces downtime and improves the utilization rate of the production line.

Key Technical Parameter Highlights

Production Efficiency: Our production line is compactly designed with an optimized process, allowing the production time of each product to be controlled within 25 seconds, greatly improving production efficiency.

Yield Rate: Through strict quality control and advanced detection systems, our production line can ensure a yield rate of over 99%, ensuring that all products meet high-standard quality requirements.

Utilization Rate: The efficient production line design and intelligent monitoring system maintain a utilization rate of over 90%, reducing downtime and improving overall production efficiency.

Choosing HONEST Intelligent as Your Supplier

You can rest assured regarding equipment debugging issues. After HONEST Intelligent’s equipment is shipped, we usually arrange for commissioning engineers to install and debug the equipment, electrical assembly engineers to handle wiring and electrical circuit exceptions, electrical engineers to deal with program actions, function optimization, and mechanical engineers to improve and optimize the equipment structure. In addition, we will also conduct itemized training for each customer’s equipment configuration, with each training session lasting 1-3 hours. The training content includes equipment structure and working principles; equipment operation methods and requirements; equipment maintenance and requirements; equipment parameter setting methods and requirements; common fault diagnosis and handling methods; helping customers better understand and use the products, and enhancing product value and utility.

If you have more interest or questions about the electronic oil pump automated production line, feel free to contact us at any time.