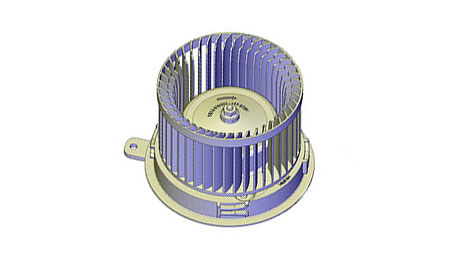

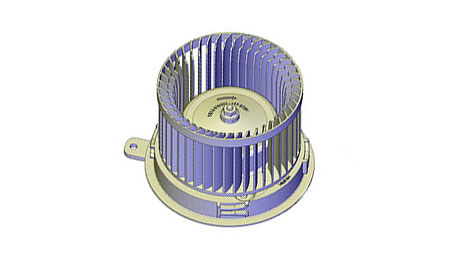

A blower is a mechanical device used for transporting, compressing, or circulating gases, widely applied in industrial production, building ventilation, and environmental control, among other fields. The blower motor is a specialized motor equipment designed to drive blowers. As the core power source of a blower, the blower motor is responsible for ensuring stable and efficient operation.

A.Types and Working Principles of Blower Motors

There are several common types of blower motors:

1.AC Induction Motor

This type of motor generates a rotating magnetic field through a three-phase alternating current. When current passes through the stator winding, it creates a rotating magnetic field. This field cuts through the rotor winding, including currents, and forms a rotor magnetic field. Ultimately, the interaction between the stator and rotor magnetic fields produces electromagnetic force, driving the rotor to rotate. Known for their simple structure, low maintenance costs, and high efficiency, these motors are extensively used in industrial production and building ventilation.

2.DC Motor

A DC motor is powered by a direct current supply. The stator produces a constant magnetic field, while the rotor, connected to the external DC power source through brushes and commutators, produces a current, forming a rotor magnetic field. The interaction between the stator and rotor magnetic fields generates electromagnetic force, driving the rotor to rotate. DC motors are renowned for their wide speed range and high control precision, though they have higher start-up and operational costs and greater maintenance difficulty.

3.Variable Frequency Drive (VFD) Motor

A VFD motor is powered by a variable frequency drive that converts AC power into adjustable frequency AC power. The motor’s speed varies according to the supply frequency, allowing for precise control of speed and torque. VFD motors offer smooth starts, reducing mechanical shock, and are well-suited for applications requiring adjustable speed and energy efficiency.

4.Synchronous Motor

A synchronous motor is powered by a constant frequency AC supply from a synchronous generator or external power source, producing a constant speed rotating magnetic field. The rotor, typically a permanent magnet or wound rotor, synchronizes with the stator magnetic field. Synchronous motors maintain a constant speed regardless of load variations and are suitable for applications requiring constant speed operation.

5.Servo Motor

A servo motor is typically used with a servo drive and control system. By precisely controlling the motor’s current and voltage, it achieves accurate control of speed and position. Servo motors offer response times and high precision and are suitable for applications requiring quick response and high accuracy.

6.Permanent Magnet Motor

Permanent magnet motors use permanent magnets to generate a magnetic field, driving the rotor to rotate. The rotor can be electrically excited winding or a permanent magnet. Favored for their high efficiency and low energy consumption, these motors also feature a simple structure and easy maintenance, making them suitable for applications requiring high efficiency and reliability.

Understanding the different types of blower motors from the above information provides a preliminary insight, which is beneficial for selecting the appropriate blower motor for production in practical work.

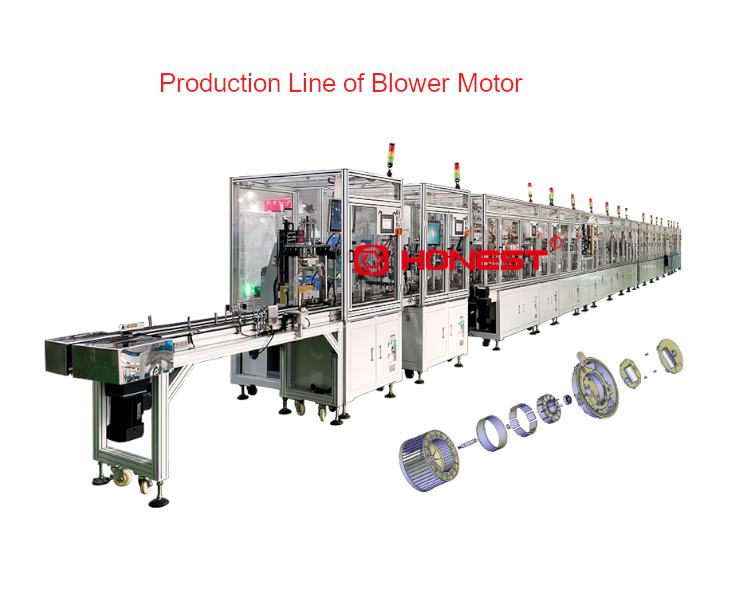

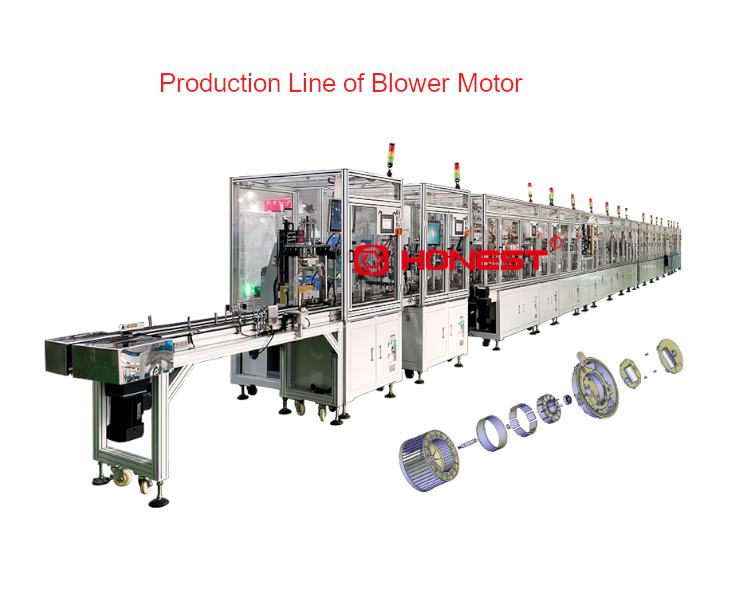

B.Automotive Blower Motor Assembly Line of HONEST Automation

HONEST Automation’ automotive blower motor assembly line is composed of a rotor, stator, base assembly, and wiring harness section. The line is configured in a loop layout with a single machine and conveyor line, along with left and right side openings, providing maximum convenience for operators and optimizing the workflow.

Key Process Description of the Production Line

Stator Section Process

1.In the core frame assembly & rear cover and rotor loading process, displacement sensors are equipped to detect whether the servo module is pressed into place, ensuring the pressing effect.

2.In the winding process, it is possible to achieve automatic loading and unloading, automatic winding, and automatic wire cutting, saving time and costs for workers.

3.In the stator performance testing process, a defective product placement area and alarm prompt function.

4.In the stator screwing process, screws are automatically arranged for output, and a screw torque mechanism and sensor are configured to detect the floating mechanism of screws. Poor torque of floating will trigger an alarm prompt.

Rotor Section Process

1.In the processes of gluing, attaching magnets, and pressing, detecting machines are equipped to ensure no missing or broken gluing, and no missing magnet assembly.

2.The high degree of automation. The processes of material loading and unloading, rotor cooling, deburring, and rotor dust removal are all automatically completed by machines without manual participation.

3.In the stator and rotor assembly process, a pressure sensor for testing resilience and a displacement sensor for checking whether the retaining ring is in place are equipped, ensuring assembly quality.

4.In multiple process links, defective product placement areas are configured. Unqualified products detected will automatically be discharged to the detective product area without interrupting the production process.

Motor Section Process

1.In multiple process links, devices such as camera inspection, visual testing, and CCD welding detection are configured to ensure that the production process has no missing components, no missing gluing, and the welding meets the expected effect.

2.The high degree of automation. The processes of automatic marking, automatic loading and unloading of motors, and automatic power-on testing are all completed by the equipment without manual participation, saving personnel working time.

C.Advantages of HONEST Automation’ Automotive Blower Motor Assembly Line

1.The blower motor production line fully utilizes processes such as torque traceability, vision inspection, depth detection, upward material recognition, mix-material recognition, pressure monitoring, and displacement monitoring to achieve error-proofing and mistake-proofing effects, with an error prevention rate of up to 100%.

2.Data access is convenient. Equipment production status is monitored in real-time, and production data is updated in real-time, shared, and transparent. It can be viewed anytime, anywhere through a mobile app or web terminal.

3.The equipment features door opening and pneumatic safety protection functions, ensuring the safety of personnel during the production process.

4.The equipment has high compatibility, supporting the production of different products, and enhancing the flexibility and adaptability of the production line.

5.Quick model change, with a model change time of less than 15 minutes, enables rapid adjustment of production modes, reducing downtime, and improving production continuity and response speed.

D.Choosing Our Products Can Help Your Production and Increase Efficiency

HONEST Automation is a professional intelligent equipment company specializing in electric motors, a national high-tech enterprise, dedicated to providing efficient and intelligent motor intelligent equipment solutions for customers both domestically and internationally. We often customize non-standard solutions and prototype services, proceeding to production only after meeting customer requirements. Additionally, HONEST Automation has a comprehensive and high-quality after-sales support service, committing to a quick response within 2 hours, 24-hour online and remote services, and establishing cooperative service points for after-salves in some overseas countries to provide localized service experiences. We provide a one-year warranty after final acceptance and offer lifelong technical services.

If you have any needs or questions about our blower motor assembly line, please contact us at any time. We look forward to the opportunity to cooperate with you.