1. What is an automobile fan motor?

The automotive fan motor is an important part of the automotive cooling system and provides cooling air to the engine and other components. It is usually installed on the front of the car and consists of a motor, fan blades and fan frame.

2. Features of automotive fan motors

High efficiency: The automotive fan motor adopts advanced motor design and manufacturing technology; its efficiency is more than 30% higher than traditional motors.

High precision: optical encoder is used to detect the position of the coil to ensure the winding accuracy is ±0.05mm.

High stability: using PLC control system, the operation is stable and reliable, and the failure rate is low.

Easy to operate: friendly human-machine interface, simple operation and easy maintenance.

Low noise: using low-noise motor design, the noise is 5-10dB lower than traditional motors.

Long lifespan: using high-quality materials and advanced manufacturing technology, the motor lifespan can reach more than 10 years.

3.The function of automotive fan motor

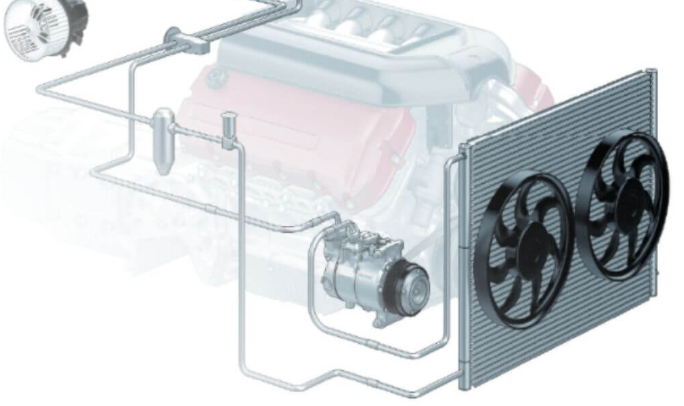

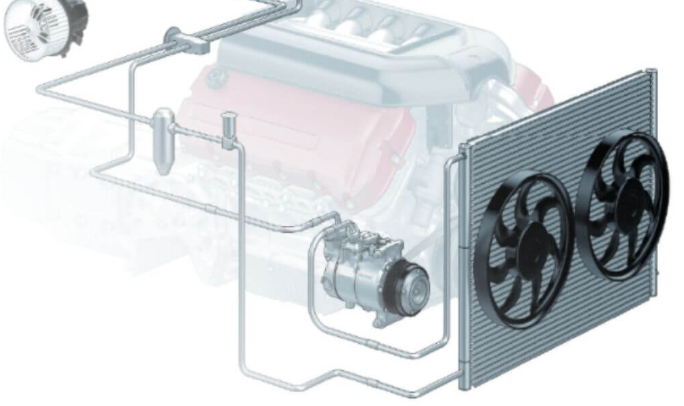

Cool the engine: the wind generated by the automotive fan motor blows through the water tank, taking away the heat generated by the engine and preventing the engine from overheating.

Dissipate heat for other components: automotive fan motors can also dissipate heat for air conditioning condensers, gearboxes and other components.

Improve engine efficiency: too high engine temperature will reduce engine efficiency. Automotive fan motors can help the engine maintain the optimal operating temperature and improve fuel economy and power.

Reduce exhaust emissions: excessive engine temperature will increase exhaust emissions. Automotive fan motors can help reduce exhaust emissions and reduce the impact on the environment.

4. Applications of automotive fan motors

Automotive fan motors are widely used in various vehicle models, including automotive, trucks, buses, engineering machinery, agricultural machinery, etc.

Specific applications:

Engine Cooling: The primary application of automotive fan motors is to dissipate heat from the engine. When the engine is working, a large amount of heat will be generated, which needs to be discharged in time, otherwise it will cause the engine to overheat. The wind generated by the car fan motor blows through the water tank, taking away the heat generated by the engine and preventing the engine from overheating.

Air conditioning heat dissipation: automotive air conditioning systems also require fan motors to dissipate heat. The condenser of the automotive air conditioner is located in front of the water tank. When the condenser absorbs the high-temperature and high-pressure gas discharged from the compressor, it needs the wind generated by the fan motor to dissipate heat and improve the cooling efficiency of the air conditioner.

Heat dissipation of other components: Many components in the car need to dissipate heat, such as gearboxes, batteries, motors, etc. Automotive fan motors can also be used to dissipate heat from these components.

5. How a automotive fan motor works

The working principle of the automobile fan motor is to use electromagnetic induction and magnetic field interaction to generate rotational force, thereby driving the fan blades to rotate and generate cooling air. Motor type and control method affect fan motor performance and efficiency.

6. The specific process is as follows:

Electromagnetic Induction: when electric current passes through the motor windings, it creates a magnetic field inside the motor.

Magnetic field interaction: there is a permanent magnet or electromagnet on the motor rotor. When the rotor enters the magnetic field inside the motor, it will be acted upon by a force and start to rotate.

Fan blade rotation: the rotor is connected to the fan blade, and the rotation of the rotor drives the fan blade to rotate, generating cooling air.

7. Features of automotive fan motor winding machines

A. Configure high-precision sensors, visual detection systems, etc.

B. The equipment is equipped with anti leakage, underinstallation, misinstallation, and post installation quality inspection.

C. The device are ergonomically designed and easy to operate.

D. The device have door opening and air pressure safety protection functions.

E. The device provides real-time prompts for various misoperations, poor states, etc.

F. When the device is abnormal, an abnormal alarm will be displayed on the screen, indicating the abnormal location, which is convenient for manual operation.

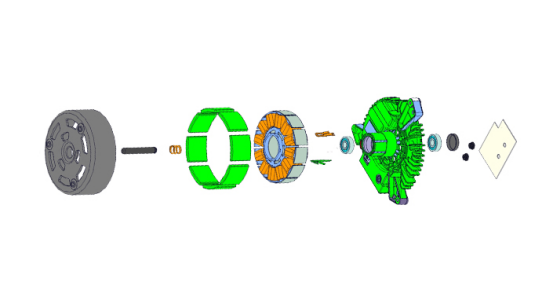

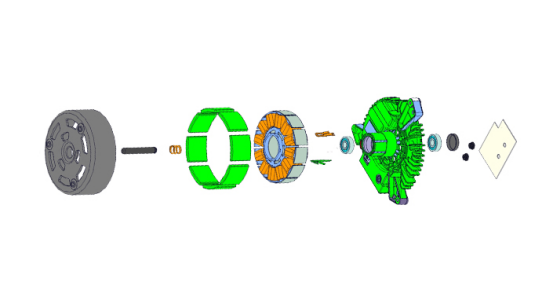

8. The automobile fan motor assembly line is a highly automated and guaranteed product quality line. The entire line mainly consists of rotor dynamic balance testing, rotor magnetization, terminal assembly and winding, stator assembly, bearing cover assembly, PCBA assembly, rear cover pressing, motor comprehensive performance testing, and other processes. The assembly line of automobile fan motors fully utilizes process methods such as torque tracing, visual inspection, depth detection, upward material identification, mixed material identification, missed assembly identification, positive aspect identification of material assembly, and pressure monitoring to achieve a foolproof and error proof effect. The error proof rate can reach 100%, and the entire production line integrates MES to achieve full traceability of product production process information.

9. HONEST HLS customized automobile fan motor

HONEST HLS provides semi-automatic and fully-automatic automotive fan motor assembly lines and automotive fan motor winding machines, which have been successfully produced in customer factories. Automation equipment solutions can be customized according to customer requirements and the equipment has strong compatibility. We provide comprehensive pre-sales, sales and after-sales services, and cooperate with local overseas automation equipment manufacturers to quickly solve problems such as installation, debugging and fault repair.

If you are looking for automotive fan motor winding and assembly solutions, welcome to contact us online to get schemes and quotes!