In the ever-evolving automotive industry, efficiency and precision are paramount. Flyer winding machine play a crucial role in the manufacturing of electrical components, particularly in electric motors and transformers. These machines are designed to enhance the winding process, ensuring high-quality results while reducing production times. This article aims to provide a comprehensive overview of flyer winding machines, including their types, working mechanisms, and the latest technological advancements. Whether you are a skilled technician or a managerial professional in the automotive sector, understanding flyer winding technology can help you make informed decisions for your operations.

1. What is a Flyer Winding Machine?

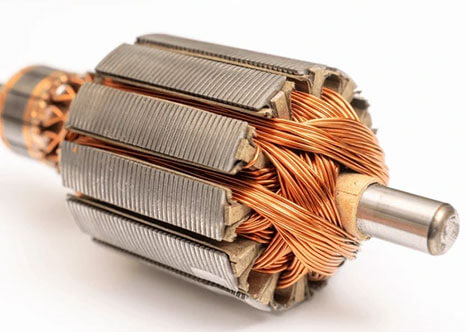

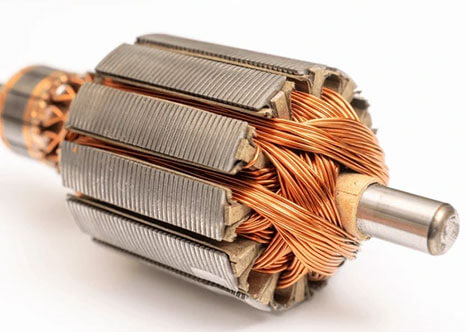

A flyer winding machine is a specialized device used for winding coils of wire around a core, typically in the production of electric motors, transformers, and inductors. The key components of a flyer winder include the flyer itself, which moves the wire around the core, and the winding table, where the core is positioned.

The operational principle of flyer winding machines revolves around the flyer’s motion, which is generally circular or elliptical. As the flyer rotates, it lays the wire around the core in a precise manner, allowing for various winding patterns. This versatility makes flyer winding machines suitable for different applications, particularly in the automotive sector, where the demand for efficient motor manufacturing is rising.

2. What is a Double Flyer Winding Machine?

A double flyer winder employs two flyers simultaneously to wind coils. This configuration significantly increases production efficiency by allowing for faster winding times and more complex coil structures.

Advantages of Double Flyer Winding Machines

Increased Production Speed: The dual flyers enable parallel processing, which reduces overall winding time.

Enhanced Coil Design Flexibility: Double flyers can create intricate winding patterns that are often required in modern electric motors, thus enhancing design capabilities.

Cost-Effectiveness: By improving production efficiency, double flyer machines can help reduce labor costs and resource wastage, making them a smart investment for manufacturers.

When comparing double flyer machines with single flyer models, the former generally provides a higher output and better adaptability for advanced motor designs. However, the initial investment and complexity of operation may be higher, making it essential for manufacturers to weigh their options based on production needs and budget.

3. Types of Flyer Winding Machines

Flyer winding machines can be categorized into several types, each designed for specific applications and winding techniques. Here are the most common types:

3.1 Single Flyer Winding Machine

Single flyer machines are the most basic type, featuring one flyer that winds the wire around a core.

Characteristics:

Ideal for simpler winding applications

Typically more affordable than double flyer machines

Suitable for lower production volumes

Applications:

Used predominantly in small-scale motor production or in situations where winding complexity is not a priority.

3.2 Double Flyer Winder

As previously mentioned, double flyer machines utilize two flyers, enhancing productivity and flexibility.

Characteristics:

Capable of handling complex winding patterns

Often includes advanced control systems for precise operation

Higher initial investment but offers better ROI for large-scale production

Applications:

Commonly employed in manufacturing high-performance electric motors and transformers, particularly in the automotive sector where design specifications are stringent.

3.3 Automated Flyer Type Winding Machines

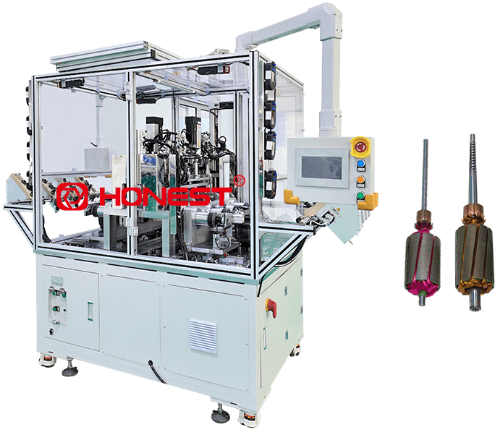

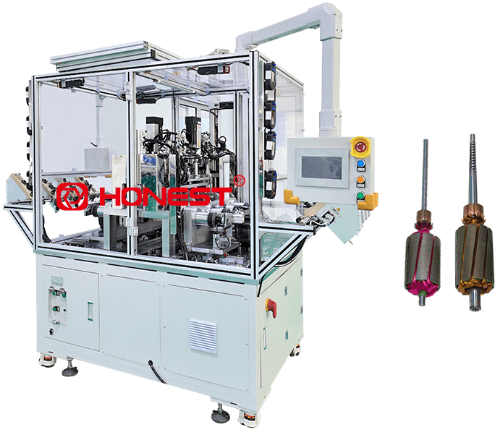

Automated flyer winding machines incorporate advanced technologies such as robotics and AI to streamline the winding process.

Characteristics:

High degree of automation minimizes human error

Enhanced data collection for process optimization

Capable of handling large volumes with consistent quality

Applications:

Primarily used in high-volume manufacturing environments, such as automotive plants that require rapid production cycles without compromising on quality.

4. Stator Flyer Winding Machine

Stator flyer winding machine are specifically designed for winding the stator coils in electric motors. The stator is a critical component that interacts with the rotor to produce rotational motion.

Importance in Motor Manufacturing

Precision Winding: The quality of the stator winding directly affects the performance of the motor. Any inconsistencies can lead to inefficiencies or failures.

Customization Options: Stator flyer winder can be tailored to produce specific winding patterns that meet the requirements of various motor designs, particularly in electric vehicles (EVs) where efficiency is crucial.

Major Application Examples

Used extensively in the production of electric vehicle motors, where high performance and efficiency are vital.

Common in industrial motors, where durability and precision are essential for operational reliability.

5. Flyer Winding Technology

As technology advances, so do the capabilities of flyer winding machines. The following are some key technological developments in this field:

Advanced Control Systems

Modern flyer winding machine are equipped with sophisticated control systems that allow for real-time monitoring and adjustments during the winding process. These systems can enhance precision and reduce the likelihood of errors.

Enhanced Speed and Efficiency

Technological advancements have led to significant improvements in the speed at which flyer winding machines operate. High-speed models can wind coils faster without sacrificing quality, which is crucial for meeting the demands of modern automotive manufacturing.

Data Integration and IoT

The integration of IoT technologies allows manufacturers to collect data from the winding process, enabling them to analyze performance metrics and make informed decisions for process optimization. This data-driven approach can lead to significant cost savings and improvements in quality.

6. The Future of Flyer Winding Machine

Market Demand Analysis

The increasing demand for electric vehicles is driving the need for efficient and reliable flyer winding machines. As automotive manufacturers pivot towards electrification, the demand for high-quality electric motor components will only grow.

Technological Innovations

Emerging technologies such as AI and machine learning are poised to revolutionize flyer winding machines further. These innovations could lead to smarter machines that can self-optimize based on real-time conditions, enhancing efficiency and reducing downtime.

Flyer winding machine are an essential component in the automotive industry, particularly in the manufacturing of electric motors. Understanding the different types of flyer winding machines, including single and double flyer models, as well as the latest technological advancements, can provide valuable insights for automotive manufacturers.

For skilled technicians and management professionals, investing in the right flyer winding technology can lead to significant improvements in production efficiency and product quality. As the automotive industry continues to evolve, staying informed about advancements in flyer winding technology will be crucial for maintaining a competitive edge.

HONEST Automation has focused on automotive motor winding and assembly equipment for over 18 years. We provide double flyer rotor winding machine, using high-precision flying fork winding technology. The equipment is suitable for the field of automotive motor production. Consult now to get a free quote and customized scheme.