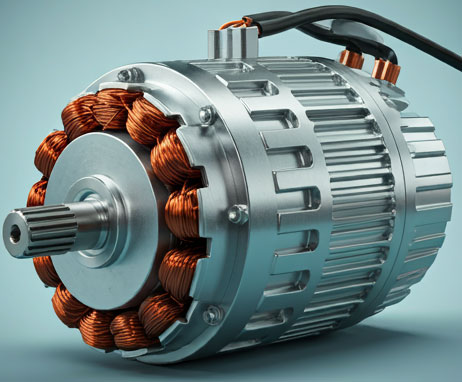

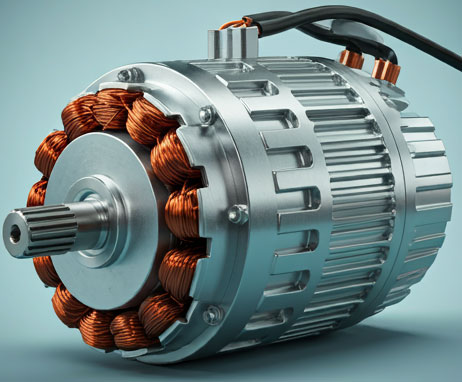

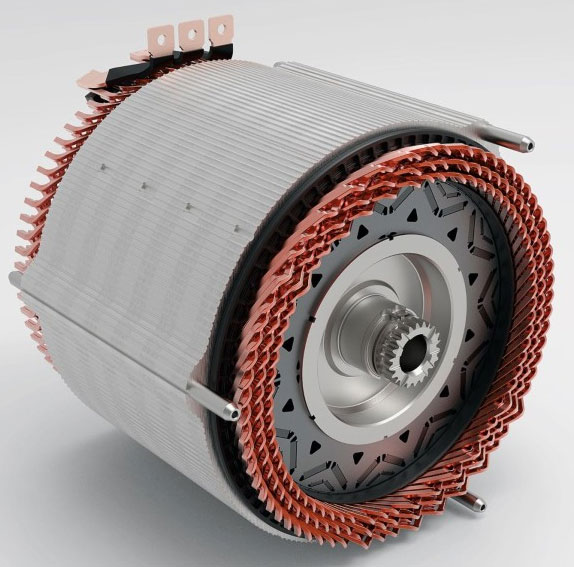

With the rise of electric vehicles (EVs), the demand for efficient and high-quality electric drive motors has grown significantly. Electric drive motors, the heart of EVs, are critical for delivering the power and efficiency required to meet modern transportation needs. However, assembling these motors with precision and speed is paramount for manufacturers seeking to meet the escalating demand. In this context, selecting the best motor assembly equipment plays a pivotal role in not only achieving production goals but also ensuring long-term performance and reliability. This article delves into the essential features of top-tier electric drive motor assembly equipment and explains why investing in such machinery is fundamental for success in the EV industry.

The Core Value of Electric Drive Motor Assembly Equipment

1. High-Precision Assembly

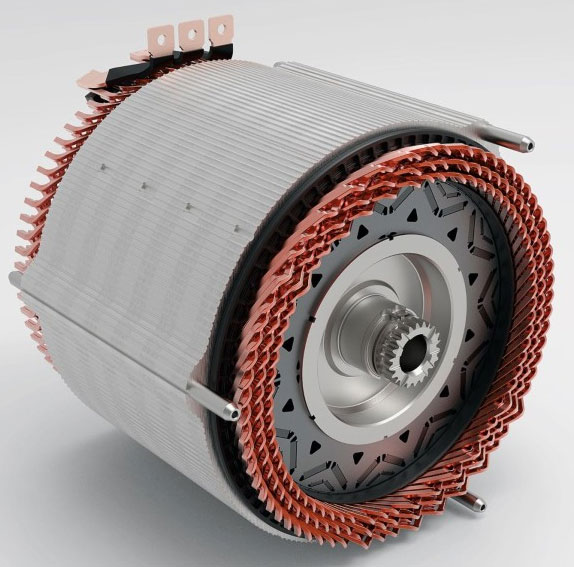

Precision in assembly is essential for any high-performance electric drive motor, particularly those designed for EVs. Motors operate at high speeds and must handle significant loads; thus, even slight inaccuracies during assembly can lead to inefficiencies, performance degradation, or even failure. High-precision assembly equipment ensures that each motor component is placed with exactitude, minimizing deviations and maximizing the motor’s lifespan and operational reliability. This precision translates into better power output, enhanced energy efficiency, and a consistent end-user experience.

2. Automation and Smart Manufacturing

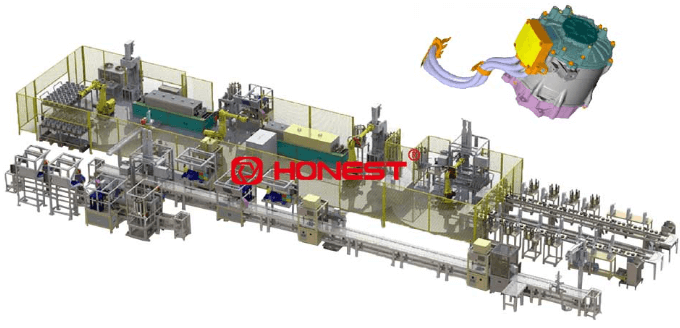

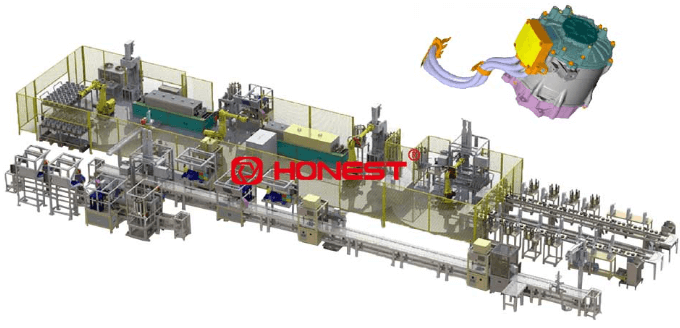

The best assembly equipment for electric drive motors offers high levels of automation, which reduces reliance on manual labor, cuts operational costs, and minimizes human error. Advanced motor assembly equipment can handle multiple tasks—from rotor and stator assembly to casing and inspection—without direct human intervention. Integrated automation not only speeds up the production process but also ensures that each motor is built to identical specifications, thereby ensuring consistency and quality at scale. Smart manufacturing, powered by the Internet of Things (IoT), can provide real-time insights into production metrics, enabling swift responses to potential issues and ensuring optimal equipment utilization.

3. Flexibility and Compatibility

In an industry as dynamic as electric vehicle manufacturing, flexibility is essential. New motor designs and requirements constantly emerge, requiring equipment that can adapt to different motor sizes, specifications, and assembly processes. High-quality motor assembly equipment often includes modular components and adjustable configurations, allowing manufacturers to reconfigure their setups quickly as needed. This adaptability reduces downtime, supports new product introductions, and keeps production lines ready for evolving customer demands.

Key Criteria for Choosing the Best Electric Motor Assembly Equipment

Selecting the right assembly equipment requires careful consideration of several factors that directly impact production quality, efficiency, and scalability.

1. Assembly Precision

From the placement of stator windings to rotor balancing and housing alignment, precision is key. The best assembly equipment provides the highest levels of accuracy, reducing tolerances and ensuring that each part fits perfectly. This minimizes wear and tear, reduces vibration, and enhances the motor’s overall performance. Precision equipment can include features like laser-guided assembly aids or AI-driven positioning to ensure each part is fitted without deviation.

2. Production Speed and Efficiency

In an industry where time-to-market is crucial, production speed is a significant competitive advantage. Efficient motor assembly equipment is designed for high throughput, balancing speed with accuracy. Automation tools, such as robotic arms and conveyor-based systems, streamline the process, ensuring that production keeps pace with demand while maintaining high standards.

3. Quality Control

Maintaining rigorous quality control standards throughout the assembly process is critical. The best assembly equipment incorporates real-time monitoring and in-line quality control checks, such as torque testing, thermal imaging, and optical inspections. This ensures that each motor leaving the production line meets or exceeds quality standards, minimizing the risk of defects and recalls, which can be costly in both financial and reputational terms.

4. Modular Design for Future Upgrades

Investing in modular equipment can future-proof the assembly line. As motor designs evolve, modular equipment can be upgraded or reconfigured rather than replaced entirely, saving both time and capital. This is particularly valuable in a fast-paced market where technology changes rapidly, as it ensures that production equipment remains relevant and can adapt to future assembly requirements.

Key Technological Features of Leading Assembly Equipment

1. Intelligent Vision Systems

Smart vision systems are a critical feature in high-quality motor assembly equipment. These systems, often powered by AI, can inspect and verify each component’s positioning during assembly. This not only enhances the overall precision but also allows for corrections in real-time. In high-volume production settings, intelligent vision systems are invaluable for maintaining quality and ensuring that any anomalies are addressed immediately.

2. Advanced Torque Control

Precise torque application is crucial during both rotor and stator assembly to ensure that components are securely but not overly tightened. Leading assembly equipment often includes dynamic torque control, which adjusts torque application based on real-time measurements, ensuring that each motor is assembled to the exact specifications. This prevents damage to delicate components while ensuring that assembled motors meet durability requirements.

3. Real-Time Data Monitoring and Feedback

Real-time monitoring systems provide valuable insights into the assembly process. By leveraging IoT and other connectivity solutions, assembly equipment can continuously monitor variables like temperature, pressure, and alignment. If an issue arises, the system can alert operators or even make automatic adjustments to maintain optimal assembly conditions. This data-driven approach enhances product quality, reduces waste, and contributes to a streamlined manufacturing process.

4. Static Control and Thermal Management

Motor assembly requires careful attention to electrostatic discharge (ESD) control and thermal management. ESD-sensitive components, such as power electronics, can be damaged during handling, so high-end equipment includes static control features to protect these components. Similarly, managing heat during assembly prevents thermal stress on materials, which could affect motor longevity and performance. Advanced assembly equipment incorporates both static and thermal control measures, ensuring that the finished motors meet stringent reliability standards.

Case Study: Real-World Success with Best-in-Class Assembly Equipment

Many leading EV manufacturers have reported remarkable improvements in productivity and quality after implementing top-tier electric drive motor assembly equipment.

1. Enhanced Productivity

For instance, a well-known electric vehicle company recently upgraded its motor assembly line with state-of-the-art equipment. This investment led to a 30% increase in production capacity, enabling the company to meet rising market demand without compromising quality. With automated precision assembly, the company could produce motors faster and at a lower cost per unit.

2. Reduced Defect Rate

Quality control enhancements, made possible through real-time monitoring and AI-driven adjustments, led to a dramatic reduction in the defect rate, bringing it down to one in every thousand units. This near-zero defect rate resulted in significant cost savings by reducing waste, minimizing recalls, and increasing customer satisfaction with reliable motors.

3. Accelerated Time-to-Market

With highly flexible and adaptive equipment, the company was able to reduce time-to-market for new motor designs by over 20%. This gave the manufacturer a strategic advantage, allowing them to quickly launch vehicles that met new market demands and technologies, thus capturing market share ahead of competitors.

The Long-Term Value of Investing in High-Performance Motor Assembly Equipment

For manufacturers in the electric vehicle sector, investing in high-performance electric drive motor assembly equipment offers substantial returns. By enhancing productivity, ensuring quality, and reducing defect rates, the best assembly equipment positions companies for success in a highly competitive market. Additionally, modularity and smart technology in these systems allow for future-proofing, ensuring that manufacturers can adapt to evolving industry needs. Ultimately, choosing the right assembly equipment is a strategic decision that not only drives immediate operational gains but also sets the foundation for long-term growth and competitiveness.

For those seeking customized solutions to optimize their motor assembly processes, consulting with leading providers of assembly equipment can be a crucial step towards achieving production excellence and securing a foothold in the future of electric mobility.

HONEST Automation provides high-quality electric vehicle drive motor assembly equipment, including drive motor stators, drive motor rotors, hairpin winding technology, and 48V starter motor assembly equipment. HONEST Automation has cooperated with many well-known automobile and motor manufacturers, using mature technology and stable equipment operation. Welcome to consult.