1. Why do coils wound on a coil winding equipment become loose?

Loose coils typically occur due to improper tension control, incorrect winding parameters, poor wire quality, equipment wear, operator errors, or unfavorable environmental conditions such as temperature and humidity fluctuations.

2. How does tension control affect motor coil winding quality?

Tension directly determines how tightly the wire is wound. If the tension controller is set incorrectly or fails, the wire may slack, causing loose and unstable coils.

3. What winding parameters can cause loose coils?

Critical parameters include winding speed, wire diameter, and pitch distance. If they are not aligned with the specific wire and application requirements, coil density and compactness are compromised.

4. Can wire quality cause loose coils?

Yes. Uneven diameter, excessive softness, or brittleness in magnet wire can affect stability during the winding process, leading to coil slack and poor insulation performance.

5. How does equipment condition impact winding results?

If key parts such as the spindle, winding drum, or guiding system are worn or damaged, they reduce wire placement accuracy and tension consistency, causing loose coils.

6. How can operator error lead to poor coil winding?

Even advanced stator coil winding machine and rotor coil winding machine require skilled handling. Incorrect feeding, setup, or operation without proper training often leads to winding defects.

7. Do environmental factors really matter in coil winding?

Yes. Temperature and humidity affect wire insulation and flexibility. For example, high humidity can soften insulation, while temperature fluctuations disrupt tension stability.

8. What are the best solutions to prevent loose coils?

Regularly check and calibrate the tension controller

Verify that winding parameters match wire and application requirements

Use high-quality magnet wire

Maintain and upgrade winding equipment

Train operators for correct procedures

Control temperature and humidity in the production environment

9. What is the ideal tension for coil winding?

The ideal tension depends on wire gauge, insulation type, and motor design. Generally, tension should be high enough to ensure compact winding but not so high that it damages insulation. Most automotive motor winding machines use programmable tension systems for precision.

10. How often should a automatic coil winding machine be calibrated?

Calibration should be done at least once every production cycle or monthly, depending on machine usage. High-volume EV motor production lines often require more frequent calibration for consistent quality.

11. Can loose coils affect motor performance?

Yes. Loose coils can cause hot spots, insulation breakdown, vibration, and reduced efficiency in motors. In automotive applications, this directly impacts EV range, safety, and reliability.

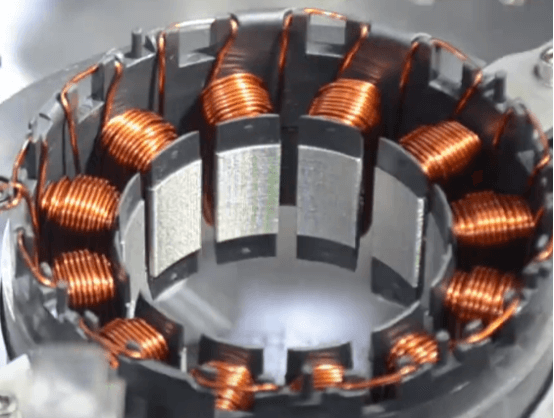

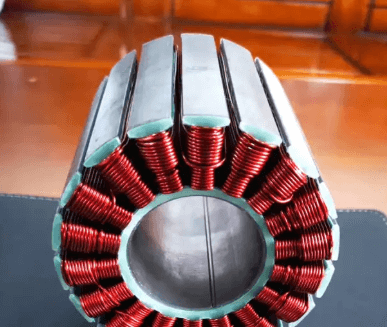

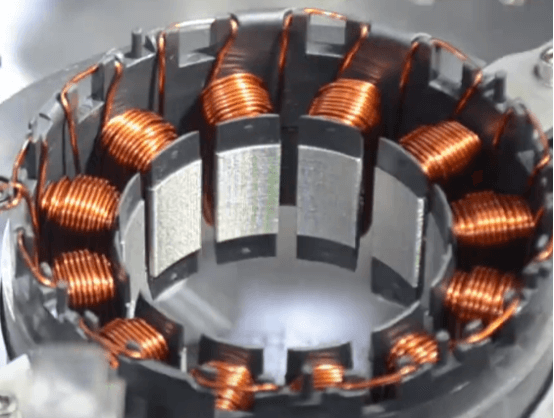

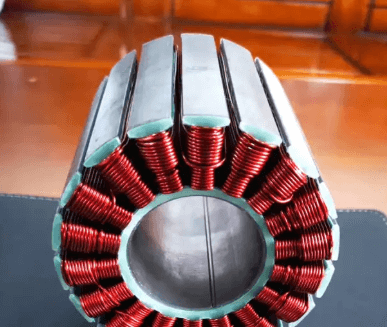

12. What’s the difference between stator coil winding and rotor coil winding in terms of quality control?

Stator coil winding requires precise slot filling and compact layering to ensure insulation integrity.

Rotor coil winding emphasizes balance and durability during rotation.

Both processes demand tight coil formation to guarantee motor efficiency.

13. How does Honest Automation solve coil winding challenges?

Honest Automation provides advanced coil winding equipment, stator coil winding machine, rotor coil winding machine, and complete motor assembly lines. With non-standard customization and expertise in automotive motors, EV drive motors, rail transit, and aerospace, the company delivers solutions that combine efficiency, precision, and digital intelligence. Welcome to consult and get free quotes and solutions.