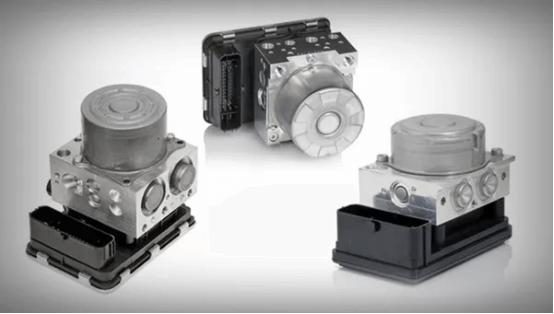

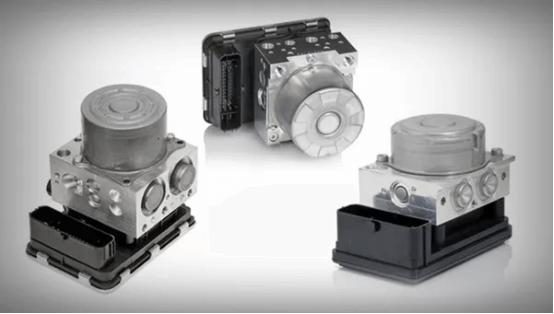

Electronic Brake System (EBS) motors play a critical role in modern automotive safety systems, ensuring precise braking and vehicle stability. As vehicles become more advanced, the demand for reliable and high-performance EBS motors has increased significantly. For automotive manufacturers, adopting advanced assembly solutions is essential not only to ensure product quality but also to enhance production efficiency and reduce operational costs.

Why EBS Motor Assembly Matters

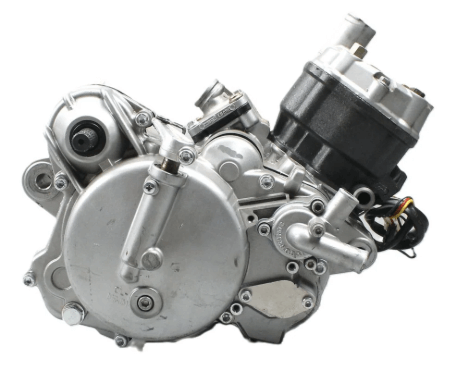

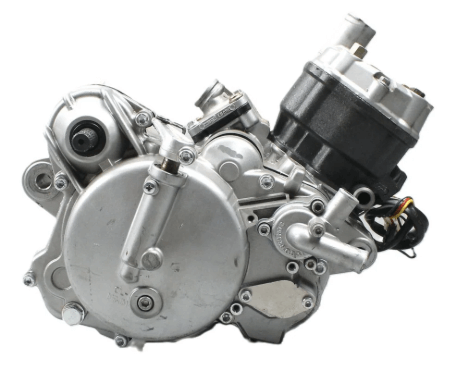

EBS motors are complex electromechanical devices. Their assembly involves winding coils, assembling rotors and stators, precise alignment, and thorough quality testing. Any deviation in the assembly process can directly affect the motor's performance, potentially compromising vehicle safety.

Traditional manual or semi-automated assembly has several limitations:

Inconsistent quality – Human error can lead to variations in coil tension, alignment, or insulation.

High defect rates – Faulty motors can result in recalls or warranty claims.

Slower production cycles – Manual assembly is time-consuming and less scalable.

Higher labor costs – Skilled labor is expensive and limited in availability.

Automated EBS motor assembly solutions address these challenges by ensuring:

Precise coil winding with minimal variation

Accurate rotor and stator assembly for consistent performance

Integrated quality checks at every production stage

Flexible production capabilities for multiple motor variants

Advanced EBS Motor Assembly Solutions

Modern assembly solutions for EBS motors combine precision automation, real-time monitoring, and intelligent software control. Key technologies include:

Automated Winding Machines

Automated coil winding ensures uniformity and reduces errors compared to manual winding. For EBS motors, where precision is critical, this improves torque consistency and thermal performance.

Stator and Rotor Assembly Systems

Robotic assembly systems handle delicate components with high repeatability, minimizing alignment errors and ensuring structural integrity.

Automated Testing & Inspection

Inline testing units check electrical parameters, insulation resistance, and mechanical tolerances. This real-time inspection prevents defective units from advancing in the production line.

Flexible Production Modules

Modern assembly lines are modular, allowing manufacturers to switch quickly between different motor specifications, supporting small-batch production and mass customization.

Benefits for Automotive Manufacturers

Implementing automated EBS motor assembly lines provides tangible benefits across multiple dimensions:

Enhanced Safety and Compliance

Every motor produced meets stringent design tolerances and safety standards, reducing the risk of failure in vehicles.

Improved Production Efficiency

Automated processes reduce cycle times, enable 24/7 operation, and optimize workflow, ensuring faster throughput.

Lower Operational Costs

Reduced labor dependency, lower scrap rates, and fewer rework cycles translate into measurable cost savings.

Scalability and Flexibility

Manufacturers can adapt quickly to increasing demand, new motor designs, or customer-specific requirements without significant downtime.

Data-Driven Insights

Modern assembly lines often integrate monitoring software, providing valuable data for continuous process improvement and predictive maintenance.

Case Study Example

Consider a mid-sized automotive manufacturer that upgraded from semi-automated EBS motor assembly to a fully automated line. The results were:

35% increase in production output

25% reduction in labor costs

50% decrease in defective units

Faster adaptation to new EBS motor designs for electric vehicles

These improvements directly translated into better product reliability, cost efficiency, and competitive advantage in the market.

Automotive manufacturers aiming to enhance EBS motor production capabilities must consider investing in automated assembly solutions. By doing so, they can ensure consistent quality, improve production efficiency, reduce operational costs, and scale production to meet growing market demands. Advanced EBS motor assembly solutions not only support current production needs but also future-proof operations as automotive technology continues to evolve.

At Honest Automation, we specialize in advanced assembly and winding solutions for automotive motors, with over 19 years of research, development, and manufacturing experience. Our expertise covers the entire production lifecycle—from solution design, equipment installation, and commissioning to operator training and on-site production guidance.

Serving leading global automotive manufacturers and suppliers, we provide a one-stop, lifetime service for your EBS motor assembly needs. If you’re looking for tailored EBS motor assembly solutions or expert advice, contact our technical specialists online today and get professional guidance for your production line.