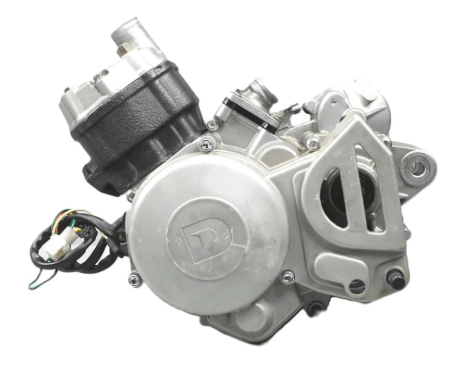

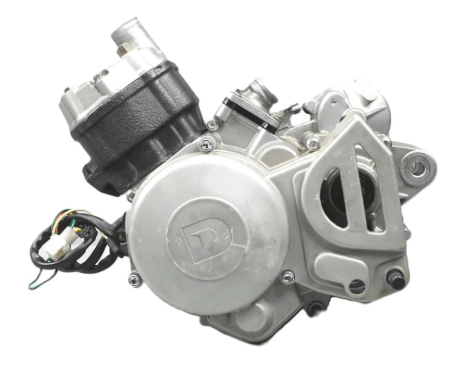

Electronic Brake System (EBS) motors are essential for modern vehicle safety and performance. For OEMs and automotive suppliers, producing high-quality EBS motors efficiently is critical to meet market demand, maintain safety standards, and remain competitive. Implementing efficient production lines is not just about speed; it also ensures consistent quality, reduces costs, and supports flexible manufacturing for multiple motor specifications.

Challenges in EBS Motor Production

Manufacturing EBS motors involves several complex steps, including coil winding, rotor and stator assembly, insulation, and testing. Traditional manual assembly or semi-automated lines present several challenges:

Inconsistent quality due to human error or manual coil tension variations

High defect rates, leading to rework or scrapped units

Slow production cycles, unable to meet high-volume demand

Limited scalability when adapting to multiple motor specifications

Increased labor costs and dependency on skilled technicians

These challenges make it difficult for OEMs and suppliers to achieve consistent production efficiency while meeting strict safety and performance standards.

Optimizing EBS Motor Production Lines

Efficient production lines integrate automation, precision engineering, and real-time monitoring. Key components of an optimized EBS motor production line include:

1. Automated Coil Winding Machines

Ensure precise and uniform coil placement

Reduce mechanical stress on wires

Increase torque consistency and motor reliability

2. Stator and Rotor Assembly Stations

Robotic assembly improves alignment accuracy

Minimizes human error

Supports high repeatability for batch production

3. Inline Testing and Quality Inspection

Electrical tests (resistance, insulation, inductance)

Mechanical checks for rotor/stator alignment

Real-time feedback for immediate correction of deviations

4. Flexible Production Modules

Quickly switch between different EBS motor designs

Support small-batch production without major downtime

Enable modular upgrades for future motor variants

Advantages for OEMs and Suppliers

Investing in efficient EBS motor production lines provides measurable benefits:

Improved Product Quality

Consistent coil winding, accurate assembly, and automated testing ensure motors meet or exceed design specifications, reducing warranty claims and product recalls.

Higher Production Throughput

Automation reduces cycle time and allows for continuous operation, enabling manufacturers to meet increasing demand for electric and conventional vehicles.

Lower Operational Costs

Reduced dependence on skilled labor, lower scrap rates, and minimized rework directly translate into cost savings.

Scalability and Flexibility

Modular production lines allow OEMs and suppliers to adapt quickly to market changes, new motor designs, or customer-specific requirements.

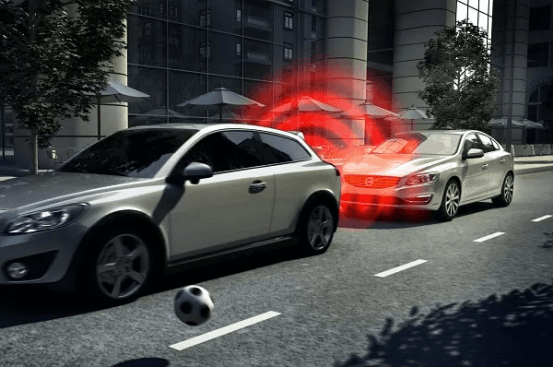

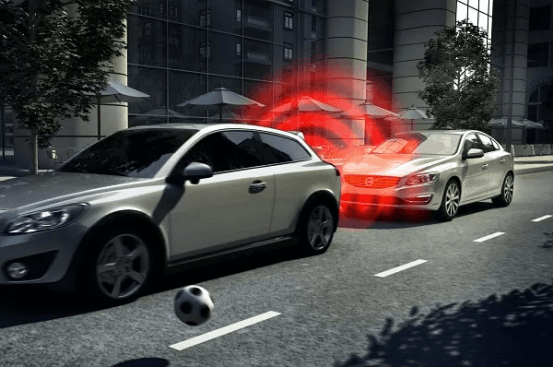

Enhanced Safety and Compliance

Automated lines ensure that every motor meets strict safety and performance standards, critical for EBS motors in braking systems.

Case Study Example

A mid-sized automotive supplier without any prior EBS motor production line invested in a fully automated EBS motor production system. The implementation brought significant benefits:

High-quality production from day one - Automated assembly ensures consistent coil winding, precise rotor and stator alignment, and reliable testing, reducing potential defects.

Rapid market entry - With a new production line, the supplier could immediately meet OEM demand for EBS motors, shortening lead times.

Cost efficiency - Although the initial investment was significant, automation reduced labor requirements and minimized scrap, lowering long-term operational costs.

Scalability and flexibility - The modular line allowed the supplier to adapt to multiple EBS motor specifications, including designs for EV applications.

Enhanced reputation with OEMs - Delivering consistent, high-quality motors strengthened client relationships and positioned the supplier as a reliable partner in the automotive supply chain.

By investing in a brand-new EBS motor production line, the supplier not only entered a critical segment of the automotive market but also established a foundation for future growth, efficiency, and technological advancement.

Future Trends in EBS Motor Production

The automotive industry is moving towards smarter, more connected production systems. Future trends include:

AI-driven process optimization - Predict and prevent defects before they occur

IoT-enabled production lines - Real-time monitoring and data analysis for better decision-making

Sustainable manufacturing practices - Reducing energy consumption and material waste

Integration with EV production - Efficiently producing EBS motors alongside other electric drivetrain components

For OEMs and automotive suppliers, investing in efficient EBS motor production lines is no longer optional—it is a competitive necessity. Automation, precise assembly, and real-time quality control enable higher production throughput, lower costs, and consistent product quality. By adopting modern production solutions, manufacturers can meet growing market demands, ensure vehicle safety, and strengthen partnerships with OEMs and end customers.

Honest Automation has over 19 years of experience in designing and manufacturing automotive motor winding and assembly equipment, delivering high-quality solutions worldwide. Our services include complete production line setup, equipment commissioning, operator training, and lifetime after-sales support.

Trusted by renowned global automotive manufacturers and suppliers, we help OEMs and component providers efficiently implement EBS motor production lines. For customized solutions, expert consultation, or guidance on optimizing your EBS motor production, reach out to our technical experts online and get professional advice today.