Mass Production of Humanoid Robots is Imminent, Ushering in a Golden Era for Axial Flux Motor

The year 2025 marks the beginning of mass production for humanoid robots, with the market scale gradually expanding. The technical characteristics of axial flux motors are highly compatible with the application requirements of humanoid robots:

Applications: High power density, high torque density, and impact resistance make them an ideal choice for leg joints, while the ultra-miniaturized design of PCB axial flux motors provides an excellent solution for precision actuators such as dexterous hands.

Technological Innovation: The unique flat structure of axial flux motors has triggered a revolution in integrated joint modules, leading to significant performance improvements.

Structural Advantages of Axial Flux Motors: High Power Density Opens a New Era of Electrification

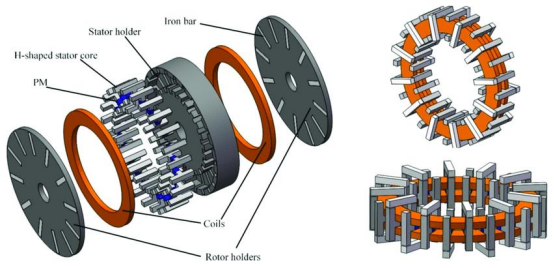

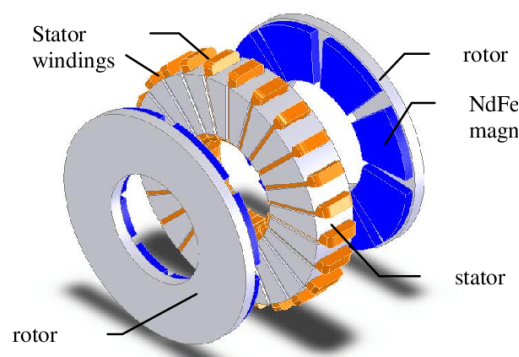

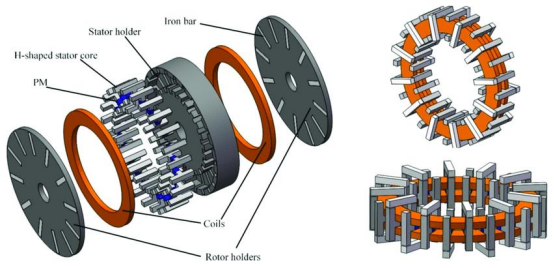

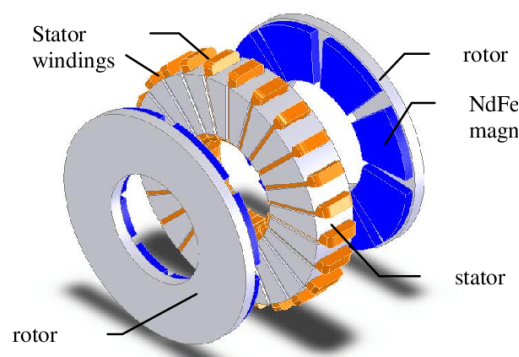

Axial flux motors adopt a disc-shaped structure with axial stator-rotor arrangement, where the magnetic field direction is parallel to the rotation axis, bringing fundamental technical advantages. Compared with traditional radial flux motors, they offer a shorter magnetic flux path, larger effective magnetic area, and higher winding density. As a result, their power density can reach up to four times that of conventional motors, torque density increases by 122%, weight is reduced by 26%, and efficiency improves by 1–2%. This structural breakthrough provides an ideal power solution for applications such as electric vehicles, electric aviation, and humanoid robots.

Humanoid Robots on the Eve of Mass Production

Currently, several companies engaged in humanoid robot development have announced plans to achieve mass production in 2025 or 2026. According to Tesla’s Q4 2024 earnings call, Elon Musk stated that Tesla plans to produce 100,000 Optimus units in 2025 and aims for commercial delivery in 2026. Similarly, the chairman of XPeng Motors also revealed plans to mass-produce L3-level humanoid robots by 2026. Therefore, 2025 is regarded as the inaugural year of mass production for humanoid robots.

According to GGII (Gaogong Robot Industry Research Institute), global humanoid robot sales are expected to reach 12,400 units in 2025, with a market size of 6.339 billion CNY. By 2030, global sales are projected to approach 340,000 units, with a market size exceeding 64 billion CNY. Looking further ahead to 2035, global humanoid robot sales are expected to surpass 5 million units, with the market size exceeding 400 billion CNY.

1. Axial Flux Motor Features Highly Compatible with Robots, Applicable to Both Leg Joints and Dexterous Hands

Motors represent one of the highest-consumption and highest-value components in humanoid robots, and the application characteristics of humanoid robots are perfectly aligned with the technical advantages of axial flux motors. Joint motors are the most critical actuators in humanoid robots, with both large quantities and high value. From a usage perspective, mainstream humanoid robots typically require 20–40 joint motors per unit. For example, Tesla’s Optimus is equipped with 28 frameless torque motors, with an estimated total value of 33,600 CNY. In addition, Optimus Gen1 is paired with 12 coreless DC motors, with a total value of 9,600 CNY.

Motor performance directly determines the robot’s mobility and operational precision. Complex actions especially require extremely high bursts of instantaneous power. However, humanoid robots are constrained by body size and the need for lightweight design, which makes motors highly sensitive to both volume and weight. Therefore, axial flux motors with high power density provide an ideal solution for humanoid robots.

Humanoid Robot Joints: The Optimal Motor Solution for Lightweight Design and Complex Motion Response

Robots impose stringent requirements on drive motors. They must not only deliver fast response and high starting torque but also feature compact size and lightweight construction, while withstanding frequent bidirectional motion and acceleration/deceleration cycles. Thanks to their unique technical advantages, axial flux motors have emerged as the ideal solution to meet these demands. At millimeter-level thickness, they can deliver high peak torque and rapid response—capabilities that are difficult to achieve with traditional radial flux motors.

Specifically, axial flux motors offer several outstanding advantages:

Flat design enables high power density in a compact form, making them particularly suitable for space-constrained robot joints.

Lightweight characteristics and low rotational inertia ensure fast responsiveness.

Optimized magnetic flux path not only enhances efficiency but also provides excellent thermal management performance.

Axial Flux Motors May Become a Potential Solution for the Next Generation of Humanoid Robots, with Vast Market Potential.

2. Axial Flux Motors: Unique Structure Delivers Superior Performance and Broader Applications

The fundamental difference between axial flux motors and traditional motors lies in the direction of the magnetic field. In 1831, the first motor invented by Michael Faraday was, in fact, an axial flux motor. However, due to the technological and manufacturing limitations of that era, issues such as machining of radially stacked stators/rotors, strong axial magnetic forces causing rotor eccentricity, challenges in stator/rotor assembly, and high costs restricted its development. As a result, it was gradually replaced by today’s mainstream radial flux motor.

Although both operate based on the same electromagnetic principles, the core distinction lies in the magnetic field orientation: in axial flux motors, the magnetic field is parallel to the rotation axis, whereas in traditional radial flux motors, the magnetic field is perpendicular to the rotation axis.

The unique motor structure and magnetic field orientation of axial flux motors deliver higher power density and efficiency. The reasons are as follows:

A. Shorter Magnetic Flux Path Improves Efficiency

The magnetic flux path refers to the route along which magnetic field lines flow within the motor. Compared with radial motors, where the flux path is perpendicular to the rotation axis, in axial flux motors the flux path is parallel to the axis of rotation, making it significantly shorter. A shorter flux path means that a smaller volume can achieve higher power output. In addition, reduced magnetic resistance and iron losses further enhance efficiency.

B. Axial Arrangement Provides Scalability

Due to their axial arrangement, axial flux motors can increase energy density by stacking additional stators and rotors while reusing basic structural components such as the housing. This structural design gives axial flux motors a unique advantage in improving power density and lays a solid foundation for their wider adoption across various application scenarios.

3. Axial flux motors are widely used in multiple fields, including new energy vehicles and electric aircraft.

The axial flux electric motor market is currently in its early industrial stage, with significant growth potential in the future. As downstream application scenarios such as electric vehicles, electric aviation, and high-end robots accelerate, the demand for high-performance motors will continue to rise. At the same time, axial flux technology is becoming increasingly mature, and its performance advantages are gradually being recognized by the market, leading to higher penetration rates across various niche segments. Furthermore, as production scales expand, manufacturing costs are expected to decrease, further driving market growth.

According to QYResearch, the global axial flux motor market is projected to expand rapidly from $142 million in 2023 to $14.48 billion by 2030, with a compound annual growth rate (CAGR) of 73.5%.

4. Axial Flux Motors Are Still in the Early Stage of Industrialization, Facing Manufacturing and Cost Challenges

Axial flux motors exhibit outstanding advantages in power density, torque, and efficiency. However, as the technology is still in the early phase of transitioning from research to industrial application, a mature industrial ecosystem has not yet been established. Before large-scale mass production can be realized, challenges remain, including complex design requirements, manufacturing precision, and material process barriers. Additionally, high technical demands and immature production equipment contribute to elevated costs, limiting the widespread adoption of axial flux motors in applications such as electric vehicles.

Air Gap Precision Control is the Core Challenge in Manufacturing

Axial flux motors feature a planar air gap structure between the stator and rotor, with an air gap area significantly larger than that of radial flux motors. This imposes extremely stringent requirements on the flatness and uniformity of the air gap surface. Because axial flux motors generate greater axial magnetic attraction than radial flux motors, the planar air gap between the rotor and stator must be maintained with exceptional uniformity.

Even minor geometric deviations can cause abrupt local changes in magnetic flux density, leading to a chain reaction of issues such as increased torque ripple, reduced efficiency, and worsened vibration and noise. In severe cases, the rotor could be pulled onto the stator, resulting in serious damage.

These strict precision requirements demand exceptionally high manufacturing and assembly accuracy. Production must rely on high-precision CNC machines, coordinate measuring machines (CMM), and other costly precision equipment. Moreover, environmental factors such as temperature, humidity, and vibration must be tightly controlled, significantly raising both manufacturing costs and technical barriers.

Axial flux motors are still in the early stages of industrial development, and the lack of industry maturity constitutes the greatest obstacle to achieving large-scale mass production. Compared with radial flux motors, which benefit from mature technical routes and standardized manufacturing processes, the production of axial flux motors remains highly dependent on manual operations, with generally low levels of automation. Although some companies have developed specialized equipment such as flat wire forming machines and slot-insertion robots, these devices suffer from limited versatility, complex debugging, and high maintenance costs, making them unsuitable for mass production.

Critical processes in rotor assembly—such as carbon fiber winding, permanent magnet installation, and dynamic balancing adjustments—still rely heavily on skilled technicians and manual labor, resulting in low production efficiency and inconsistent product quality. The quality inspection stage lacks standardized testing equipment and methods; key parameters such as air gap uniformity and insulation strength still depend on expensive imported equipment, leading to long testing cycles and high costs.

Industrial chain collaboration is even less mature. Due to the novelty of the technology and small market demand, the overall development level of the axial flux motor supply chain is far below that of radial flux motors. Key components, such as high-precision bearings, specially shaped permanent magnets, and customized insulation materials, require dedicated development and small-batch production from suppliers, resulting in high procurement costs, long lead times, and inconsistent quality. Specialized manufacturing equipment is mainly imported or self-developed, involving significant investment and high technical risk.

More importantly, axial flux motors currently lack unified industry standards in design specifications, manufacturing protocols, and testing methods. The technical routes of different companies vary greatly, making it difficult to form large-scale supply chain collaboration. As a result, the industry remains in an early stage characterized by fragmented, small-scale trial production.

5. Honest Automation has successfully delivered humanoid robot motor production lines.

Honest Automation specializes in motor stator and rotor winding and assembly equipment, with products widely used in new energy vehicles, humanoid robots, and other fields. Honest Automation provides prototyping and small-batch production for axial flux motors and offers a comprehensive one-stop service, including pre-sales solutions, equipment assembly and delivery, as well as lifetime after-sales training and on-site support.

If you require humanoid robot motor assembly line, humanoid robot assembly, or axial flux motor assembly, as well as prototyping and small-batch production, please contact Honest Automation for customized expert advice.