In modern motor manufacturing, especially in the field of new energy vehicle motor production, hairpin winding technology is gradually becoming a mainstream solution. In order to improve winding efficiency and ensure accuracy, advanced hairpin making machine (or hair pin making machine) have emerged, which can produce high-quality hairpin windings in a shorter cycle. This article will introduce hairpin forming technology in detail, analyze the characteristics and functions of hairpin making machine and the unique advantages brought by their efficient production.

What is Hairpin Forming?

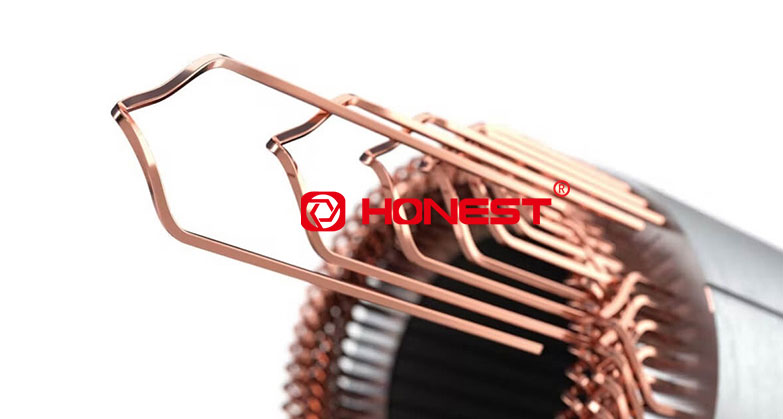

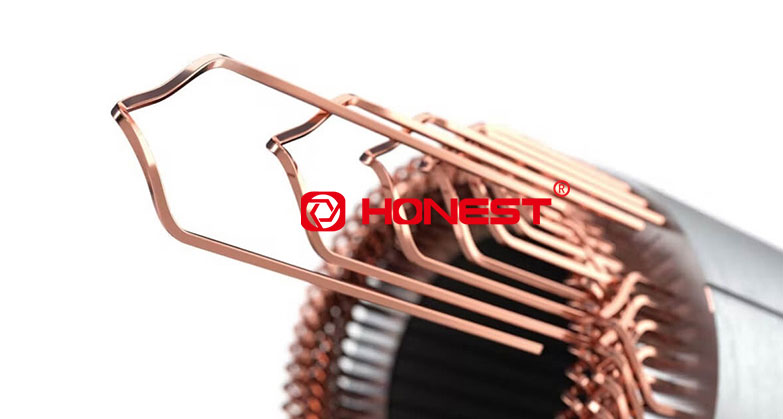

Hairpin forming is a manufacturing process dedicated to motor stator windings. It achieves high-density, high-performance windings in motor stators by forming flat copper wire into a "hairpin" shape. The hairpin forming process requires extremely high precision and consistency to ensure the stability and efficiency of the motor. Therefore, efficient hairpin forming requires not only advanced equipment support, but also relies on precise operating procedures and testing systems.

Key Features of Hairpin Making Machine

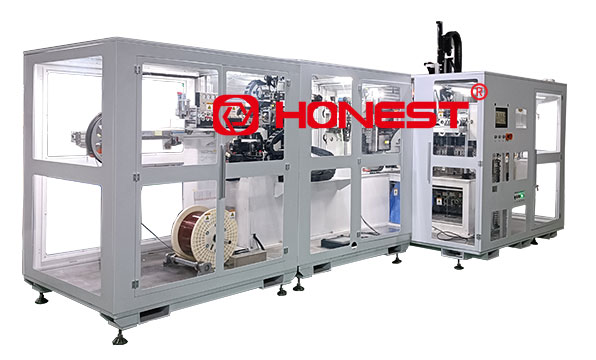

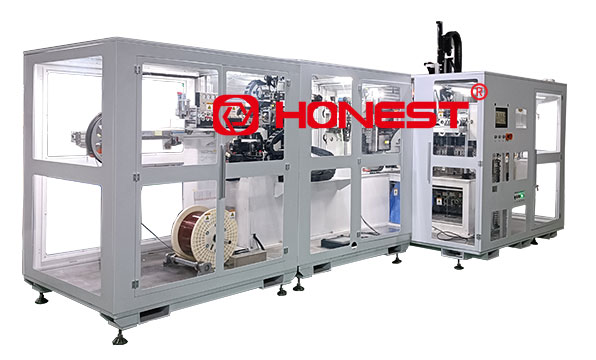

A modern hairpin making machine is a highly automated device specifically designed for the production of hairpin windings. Its functions cover multiple steps from copper wire processing to forming to quality inspection, ensuring efficient and high-quality production of windings. The following are the main functions of this type of equipment:

Hair pin straightening: Before forming, the copper wire must be accurately straightened to ensure the quality of subsequent bending and forming.

Paint stripping function: The equipment supports two optional methods of mechanical paint stripping and laser paint stripping to meet different production needs. Mechanical paint stripping is suitable for batch conventional copper wire, while laser paint stripping provides higher precision.

2D bending and 3D forming: The hairpin making machine can perform precise 2D bending and 3D forming of copper wire to ensure that each hairpin has a consistent size and shape to meet the installation requirements of the stator. In particular, with the help of 3D mold integrated forming, the equipment can automatically complete the production of all wire types and wire cups.

Paint damage detection: During the paint stripping process, the equipment is equipped with an automatic detection system to ensure that the copper wire paint is not damaged to avoid affecting the motor performance due to paint damage.

Plug-in cup and withstand voltage test: The equipment can automatically complete the installation of the plug-in cup, and at the same time perform 100% online withstand voltage test on each hair pin, and unqualified hair pins will be automatically rejected. Such a testing process greatly improves the stability of product quality.

Intelligent line replenishment: For defective products, the equipment can automatically identify and replenish the corresponding hair pins, so as to insert them into the specified position. This function avoids downtime caused by human intervention and improves production efficiency.

Missing line display: During the operation of the equipment, the missing line display function can promptly remind the operator to handle it to ensure the continuity and stability of production.

Technical Advantages of HONEST Automation Hairpin Making Machine

Wire making efficiency 1.5 seconds: The advanced hairpin making machine can achieve an efficient wire making speed of 1.5 seconds per strand. This efficiency can meet high-volume requirements, significantly shorten the production cycle, and is very suitable for large-scale production.

Compatible with multiple wire types: The equipment is compatible with more than 36 wire types, and can be adjusted accordingly according to different motor designs and requirements, which improves the adaptability of the equipment.

Applicable layers: The equipment supports up to 12 layers of winding layers, which is suitable for various types of motor manufacturing needs and has extremely high flexibility.

3D mold integrated molding: The equipment adopts 3D mold integrated molding technology, so that the production of all wire types can be completed automatically, which not only improves production efficiency, but also reduces production errors.

Intelligent detection and rejection system: The hairpin making machine has a complete detection and rejection system, which automatically rejects defective products through online withstand voltage detection, ensuring the high-quality output of each hairpin winding.

How to Choose an Awesome Hairpin Making Machine?

When choosing a hairpin making machine, you should consider production needs, efficiency, equipment compatibility, and cost budget. Here are a few key points:

Wire making speed: High wire making efficiency is suitable for mass production needs. Such equipment can not only meet the needs of efficient production, but also save production time.

Ease of operation: Choose a hairpin making machine that is easy to operate, especially a machine with an automated and intelligent control system, which can greatly reduce training costs and operating errors.

Stability and maintenance cost of equipment: High-quality equipment usually has a long service life and low maintenance costs. By choosing a high-quality hairpin making machine, you can reduce production interruptions caused by frequent downtime and improve overall production efficiency.

Compatibility: Different motor designs and sizes require different hairpin specifications. Purchasing a hairpin making machine that supports multiple specifications can increase the flexibility of the equipment and adapt to the manufacturing needs of different motors.

Application and future development of hairpin forming technology

With the rapid development of the electric vehicle market, hairpin windings are increasingly used in new energy vehicle motors. Compared with traditional winding processes, hairpin forming can increase the density of motor windings, reduce copper loss during motor operation, improve overall efficiency, and extend driving range. Therefore, the market demand for hairpin making machine will further expand.

In future technological developments, HONEST Automation hairpin forming making machine will continue to move towards intelligence and automation. The new equipment will have higher compatibility, support more line types and layer selections, and meet the manufacturing needs of various complex motors. In addition, the equipment will also be equipped with more advanced detection and data tracking functions to achieve real-time monitoring of the production process, fault warning, and intelligent analysis of production data.