The fundamental production process of hairpin motor stators consists of the following steps: inserting slot insulation, fabricating hairpins, inserting hairpins into the slots, forming end rings, welding the end rings, connecting the star point, and performing insulation treatment on the welded joints. Notably, wire forming, paper forming, and slot insulation insertion are carried out concurrently.

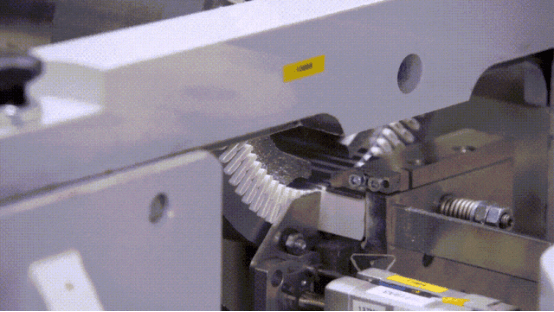

Slot Insulation Insertion:

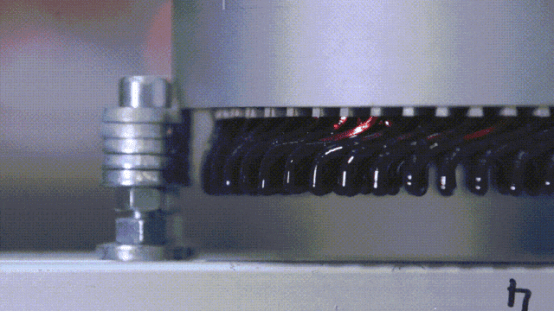

In hairpin motor stator, insulation paper is placed between the stator slots and conductors to ensure proper insulation between different-phase conductors as well as between the conductors and the stator core.

Generally, the slot insulation insertion process includes paper forming, paper cutting, and slot insertion. Common slot paper forming methods are cold forming and hot forming.

Regarding the shapes of the insulation paper, O-shaped, C-shaped, B-shaped, and S-shaped papers are used. O-shaped is the most commonly applied. B-shaped and S-shaped papers can significantly improve insulation performance, but their manufacturing processes are more complex. Additionally, they result in lower copper slot fill rates and reduced process stability.

For certain motors, due to process requirements, two sheets of insulation paper must be used to separate adjacent conductors of different phases within the stator slots. This increases the space occupied by the insulation, thereby reducing the motor’s power density.

Furthermore, since the two sheets of insulation are not interconnected, it is currently difficult to insert them automatically into the stator slots using machinery. This has become a major challenge in the automation of hairpin motor manufacturing.

Hairpin Motor Coil Forming:

The hairpin motor wire manufacturing for the stator core primarily involves several process types, including I-PIN, Hairpin, and Wave Winding.

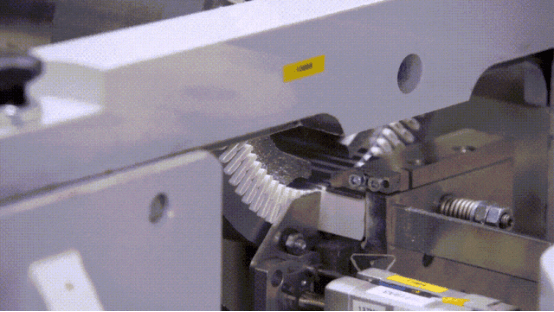

Hairpin coils undergo a series of processes, including straightening, enamel removal, cutting, and forming. Enamel removal is typically carried out using either laser stripping or traditional methods. While the conventional method has lower costs, it may result in incomplete enamel removal or damage to the copper wire.

The forming processes mainly include stamping and spring-machine forming. The latter has a higher cost but causes less damage to the copper wire.

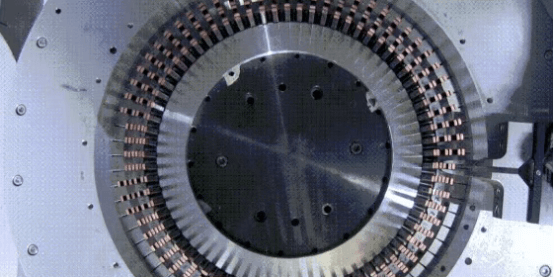

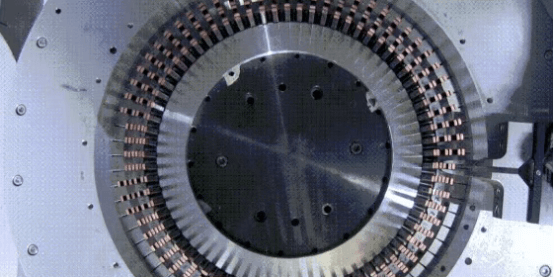

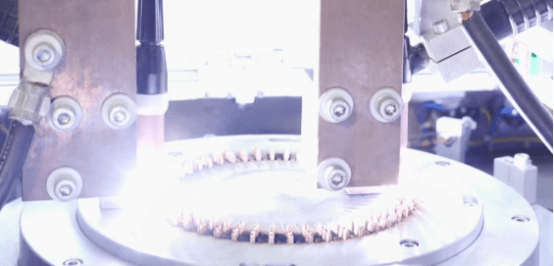

Coil Insertion:

The hairpin motor coils are first placed into a profiling fixture, and then all coils are gripped together and inserted into the stator core, pressed to the specified design dimensions.

In this process, cross-layer automatic insertion has evolved from the previous 2-layer and 4-layer methods to the latest 6-layer and 8-layer techniques. Some domestic manufacturers have already achieved production using these advanced methods.

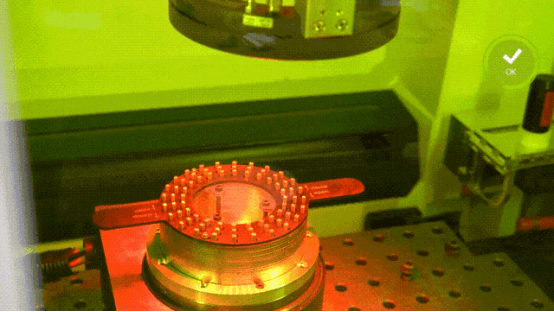

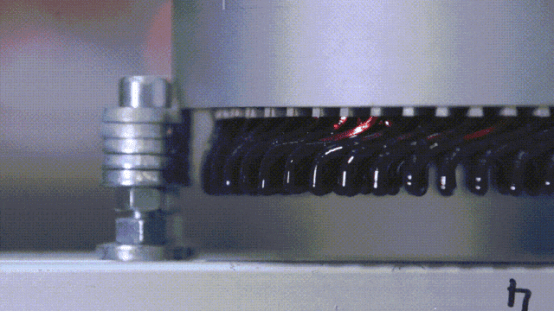

End Flanging, Head Twisting, and Welding:

The fixture holding the stator is moved to the designated cross-layer flanging station. The flanging mechanism grips the upper ends of all hairpin layers except for the innermost two layers and pulls the hairpins outward, sequentially performing the end flanging on all layers.

The twisting station and the stator are moved into the working position. The flanging mechanism extends to press against the ends of the innermost two hairpin layers, aligning them with the twisting mechanism. The flanging mechanism then retracts, allowing the ends of the innermost layers to be inserted into the twisting station. The inner and outer molds of the twisting mechanism rotate in opposite directions, completing the twisting of the innermost two hairpin layers. Subsequently, the twisting process is applied to all other hairpin layers.

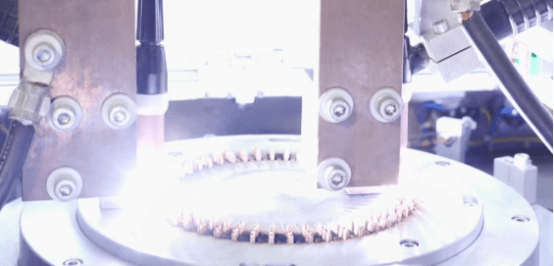

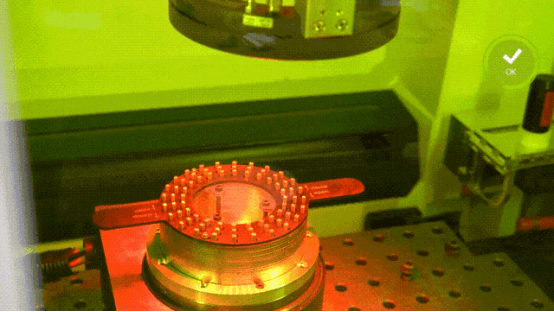

The existing welding methods mainly include laser welding and TIG (argon arc) welding. Both techniques achieve electrical connections by creating weld points through instantaneous high temperatures that melt the copper. Some manufacturers also adopt CMT (Cold Metal Transfer) welding or other alternative welding methods.

The existing laser welding and TIG (argon arc) welding techniques have two main drawbacks:

Both methods require instantaneous high temperatures to melt the copper, which can easily damage the enamel coating of adjacent wires, reducing insulation reliability.

Hairpin coils or single-sided coils that form the stator winding of a hairpin motor consist of a large number of hairpins, requiring many weld points. Since laser or TIG welding is typically performed on each weld point individually, this significantly reduces the production efficiency of hairpin stators.

Coating and Varnishing:

Currently, coating materials are mainly available in two forms: powder and liquid. The varnishing processes primarily include traditional dip varnishing, vacuum dip varnishing, vacuum pressure dip varnishing, drip varnishing, as well as the EUV (Electrostatic Ultrasonic Varnishing) process.

Stator Potting:

Thermal management has long been a major challenge for many automotive manufacturers. The increasing demands for higher driving range and power density place greater requirements on motor heat dissipation, with modern motors relying heavily on cooling systems for thermal management.

Currently, motor manufacturing primarily uses traditional impregnation processes; however, these methods often suffer from poor thermal performance, low mechanical durability, and incompatibility with organic oils. Under these circumstances, vacuum potting technology has emerged as an effective solution.

For vacuum potting, the required potting resin should have the following characteristics:

Good flowability before curing: The resin must be able to penetrate into the uneven gaps on the surface of the windings. After potting, the workpiece surface should be smooth and even, ensuring that the motor’s rotating components have a nearly uniform moment of inertia. This reduces vibrations caused by sudden changes in speed or direction due to thermal stress and mechanical load, and minimizes the resistance imposed on the rotating parts by the cooling medium.

Strong adhesion and mechanical robustness: The resin should adhere firmly to the motor windings and possess high resistance to thermal shock, as well as sufficient mechanical strength.

High thermal conductivity: The resin should have a high thermal conductivity to reduce temperature gradients between the inner and outer surfaces of the potting material. This allows the heat generated during motor operation to be quickly conducted to the workpiece surface, while also minimizing internal stresses caused by temperature differences.

Excellent electrical insulation and oil resistance: After potting, the stator forms an integrated structure, which improves heat dissipation, modal stiffness, and damping performance of the stator. As a result, temperature rise and vibration noise are reduced, while moisture resistance, shock resistance, and corona resistance are enhanced.

Honest Automation offers complete solutions for hairpin motor production, including hairpin motor assembly lines, prototype production, as well as single-station, semi-automatic, and fully-automatic assembly equipment. Contact us now to get expert advice.

Tel/WhatsApp/Wechat: +8618923732990

E-mail: sales@honest-hls.com