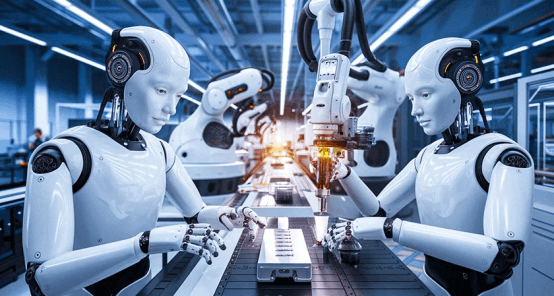

With the rapid development of artificial intelligence and mechatronics technology, humanoid robots are transitioning from science fiction to reality, becoming the core focus of next-generation intelligent equipment. From Tesla’s Optimus to the strategic deployments of various major tech companies, the humanoid robot industry is entering a stage of explosive growth. Facing this historic opportunity, Honest Automation leverages its years of experience in motor automation equipment to provide the industry with professional and reliable humanoid robot assembly equipment and motor solutions.

Development Trends and Core Challenges of Humanoid Robots

As one of the ultimate forms of robotic technology, humanoid robots are demonstrating tremendous potential across industries such as manufacturing, service, and healthcare. According to industry forecasts, the global humanoid robot market is expected to surpass USD 100 billion by 2030. Three major trends drive this growth:

Refined Bionic Structures: Modern humanoid robots need to replicate the flexibility and load-bearing capacity of human joints.

Efficient Power Systems: Increasing demands for power density, response speed, and energy efficiency.

Urgent Need for Mass Production: Transitioning from laboratory prototypes to large-scale production requires mature assembly processes.

However, the assembly precision of the humanoid robot’s core components—joint motors—directly determines the robot's overall performance. Traditional assembly methods struggle to meet the high standards of consistency, reliability, and efficiency required by humanoid robots. This is precisely where Honest Automation’s solutions provide significant value.

Core Advantages of Honest Automation’s Humanoid Robot Motor Assembly Solutions

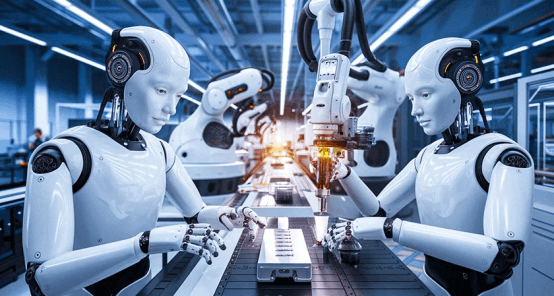

High-Precision Frameless Torque Motor Assembly Equipment

The “joints” of humanoid robots—the frameless torque motors—have assembly precision that directly affects the robot’s motion smoothness and lifespan. Honest Automation’s self-developed fully automated frameless torque motor assembly line achieves:

Micron-Level Positioning Accuracy: Ensures a uniform air gap between the stator and rotor, reducing cogging torque fluctuations.

Intelligent Torque Calibration: Integrates high-precision sensors to monitor torque variations in real time during the assembly process.

Flexible Production Design: The same equipment can accommodate the assembly of frameless motors of different sizes and specifications.

Fully Automated Joint Motor Assembly System

Humanoid robots require multiple joint motors to work in coordination, with each joint being a compact precision transmission system. Honest Automation’s joint motor assembly equipment features:

Multi-Station Coordinated Operation: Simultaneously performs complex processes such as magnet insertion, stator pressing, and encoder installation.

Online Inspection and Compensation: Real-time monitoring of key parameters such as axial clearance and radial runout, with automatic compensation and adjustment.

Data Traceability System: Records assembly parameters for each motor, providing data support for subsequent optimization.

Rapid Prototyping and Small-Batch Production Solutions

For companies in the R&D stage, Honest Automation offers flexible motor prototyping services, including:

Modular Prototyping Platform: Quickly adapts to the assembly of motor prototypes with different structural designs.

Small-Batch Trial Production: Supports a smooth transition from prototypes to small-scale production.

Technological Innovations of Honest Automation Equipment

Honest Automation’s equipment integrates multiple industry-leading technologies:

Intelligent Vision Guidance System: Utilizes high-resolution industrial cameras and advanced algorithms to achieve precise component positioning and pose recognition, ensuring assembly accuracy.

Adaptive Force Control Technology: Dynamically adjusts pressure and position based on real-time feedback during the assembly process, preventing component damage.

Digital Twin Platform: Simulates and optimizes assembly processes in a virtual environment, significantly reducing equipment commissioning time.

IoT Data Collection: Monitors equipment status and product quality in real time, enabling predictive maintenance and quality traceability.

Core Value Delivered to Clients

By choosing Honest Automation’s assembly solutions, clients gain:

Improved Product Consistency: Automated equipment ensures that each motor meets the same performance standards.

Reduced Production Costs: Minimizes reliance on skilled labor while improving production efficiency and material utilization.

Accelerated Time-to-Market: Mature solutions significantly shorten the time from design to mass production.

Intellectual Property Protection: Strict confidentiality agreements and protective measures safeguard clients’ technologies.

Ongoing Technical Support: Full lifecycle support from equipment installation to subsequent upgrades.

At this critical moment, as the humanoid robot industry is on the verge of explosive growth, having reliable and efficient motor assembly capabilities will become a core competitive advantage for companies. Honest Automation is committed to being your most trusted partner, providing complete solutions from motor prototyping to mass production.

Whether you are an innovative company developing the next generation of humanoid robots or a supplier focused on enhancing joint motor performance, Honest Automation can tailor the most suitable automated assembly equipment for your needs.

Contact our expert team today to explore how we can provide customized solutions for your projects and work together to advance humanoid robot technology.

Our first humanoid robot motor production line has successfully achieved mass production at a client’s factory, making us your trusted partner for humanoid robot assembly automation.

The future of humanoid robots begins with precise assembly today. Leave us your specific requirements now, and let us help you seize the technological advantage.