A torque motor is a special type of motor with soft mechanical characteristics and a wide speed regulation range. It features low speed, high torque, strong overload capacity, fast response, good linearity, and low torque ripple. Unlike conventional motors that deliver constant power, the torque motor outputs constant torque.

◆ The main characteristic of a torque motor is its soft mechanical nature, which allows it to operate in a stalled condition. When the load torque increases, the motor automatically reduces its speed while increasing the output torque. When the load torque remains constant, the motor speed can be adjusted by varying the terminal voltage. However, the speed regulation accuracy is not high. To stabilize the motor, a tachometer can be installed on the shaft along with a controller. By comparing the voltage signal from the tachometer with the reference voltage from the controller, the motor’s terminal voltage is automatically adjusted, ensuring stable operation.

◆ Torque motors, with their low speed, high torque, strong overload capacity, fast response, good linearity, and small torque ripple, can directly drive the load without the need for reduction gears. This improves the overall system accuracy.

◆ To meet different performance requirements, torque motors are designed with three structural types: small air gap, medium air gap, and large air gap.

Small air gap structure: suitable for general applications, lower cost but limited accuracy.

Large air gap structure: eliminates cogging effects, reduces torque ripple, minimizes nonlinear magnetic reluctance variation, and improves linearity. The increased magnetic air gap also reduces armature inductance and the electrical time constant. However, the manufacturing cost is higher.

Medium air gap structure: provides performance superior to small-gap motors and close to large-gap motors, but with smaller size and lower manufacturing cost compared to large-gap designs.

◆ Applications of torque motors include: winding, unwinding, stepless speed regulation, and stall operation.

◆ Torque motors are categorized into framed and frameless types.

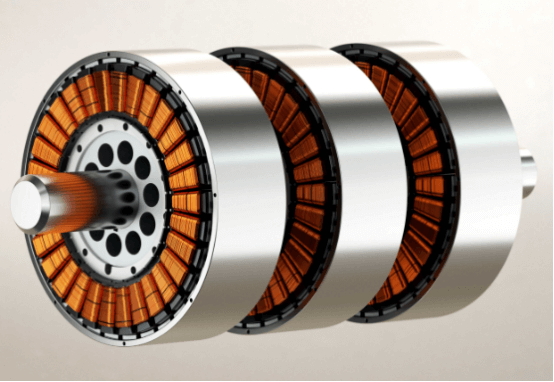

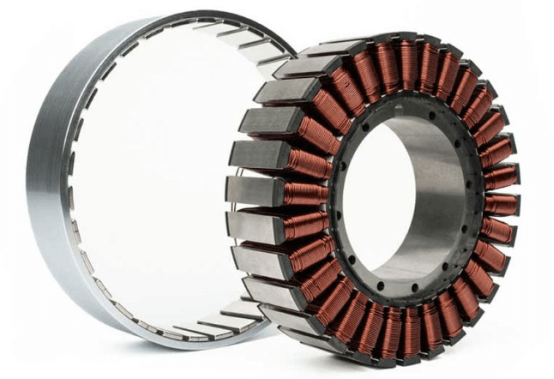

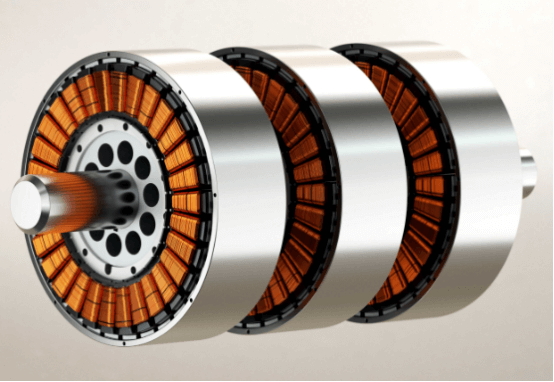

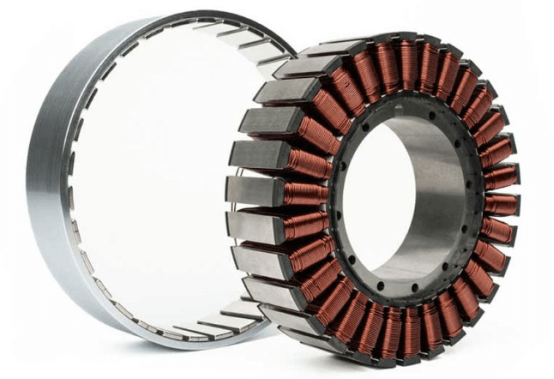

Frameless torque motor have gained prominence with the rapid development of artificial intelligence, especially in collaborative and service robots. The demand for such robots is rising, requiring motors with compact size, high power density, and customized specifications. Unlike conventional stepper or servo motors, the joint modules of robots integrate the motor, gearbox, brake, encoder, and driver into very limited space. Frameless torque motors, without an outer housing, meet these requirements. They are hollow inside, providing convenient cable routing and allowing more compact designs. They also offer higher power density and can deliver greater torque for the same motor size.

Frameless torque motors provide only two separate components—the stator and the rotor—without an output shaft, bearings, or end covers. A frameless motor can be directly coupled to the load using the same bearing system that supports both the load and the motor itself. This design eliminates the shaft, bearings, end covers, and couplings, thereby reducing motor size, weight, and structural complexity, while further improving servo stiffness and dynamic response. Frameless motors can also integrate essential components such as Hall sensors, as well as additional position feedback devices like encoders or resolvers.

◆ The structural characteristics of frameless torque motors allow them to be directly embedded into mechanisms.

Their hollow design facilitates cable routing and enables high integration, which helps reduce the overall size of the end product. In addition, frameless torque motors deliver high torque, stable performance, and superior precision.

◆ Frameless torque motors: indispensable for robotics

Frameless motor have broad application potential in humanoid robots. They can be used to replicate joint movements or simulate muscle extension. Tesla’s humanoid robot Optimus, for example, integrates frameless torque motors within its 14 linear actuators and 14 rotary actuators, achieving precise motion control while saving space.

At Honest Automation, we provide advanced assembly equipment for humanoid robot frameless torque motors, humanoid robot joint motors, and complete humanoid robot motor integration. Our solutions support motor prototyping, small-scale production, and large-scale manufacturing, ensuring high precision and stable operation. These motors are widely applicable in humanoid robots, automobiles, electric vehicles, aerospace, and medical equipment. Contact us today to receive expert advice and customized solutions tailored to your needs.