The steering wheel is an essential component of modern automobiles, allowing drivers to control the vehicle’s direction by manipulating the steering wheel. The power steering motor is a crucial part of the modern automotive steering system, playing a significant role in the Electric Power Steering system.

The Structure of the Power Steering Motor

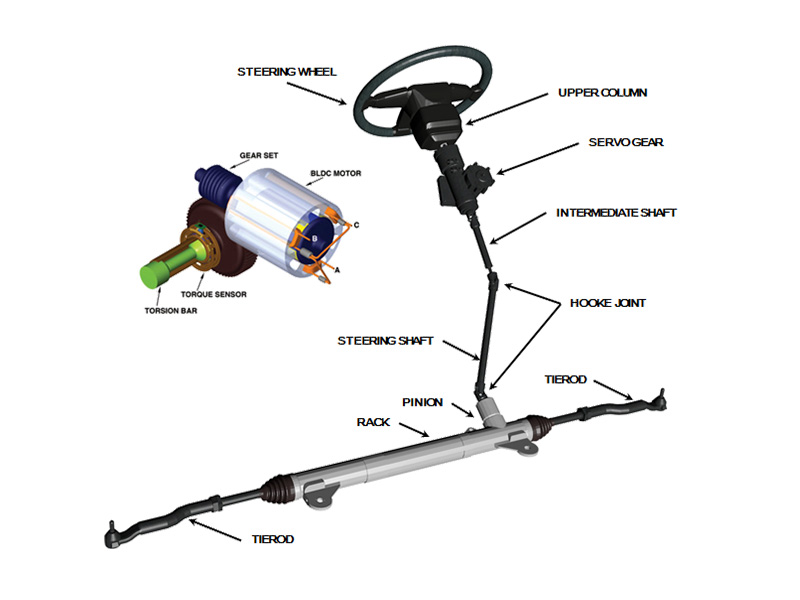

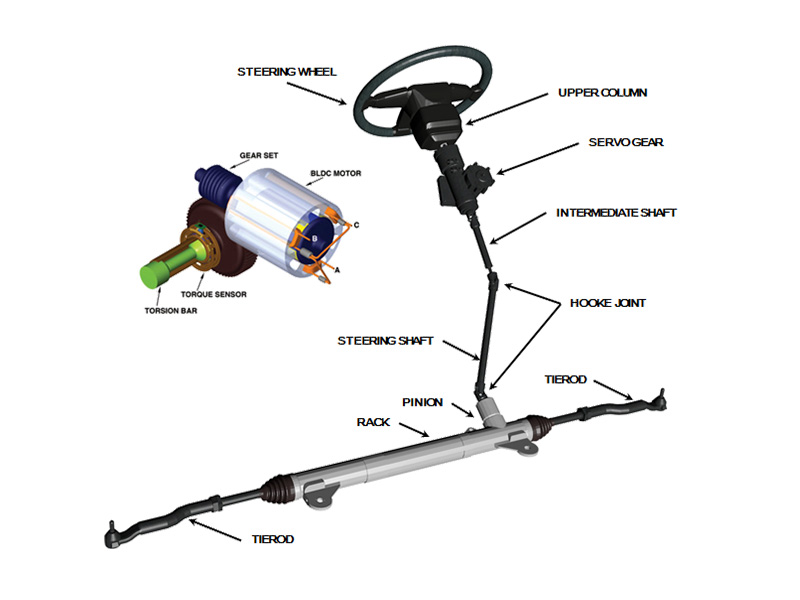

The structural composition of the power steering motor mainly includes the following key components:

A. Motor: It is the core part of the power steering motor, and usually uses a permanent magnet DC motor or an AC motor. It is responsible for generating the necessary auxiliary torque based on the driver’s operation and the vehicle’s driving condition;

B. Reduction Mechanism: Since the motor usually generates high rotational speeds, while actual steering requires lower speeds and higher torque, the reduction mechanism converts the high-speed rotation of the motor into lower speeds and higher torque suitable for wheel steering;

C. Sensors: Including torque sensors steering angle velocity sensors, and so on. It is used to monitor the torque and steering speed applied by the driver through the steering wheel, and feedback this information is to the Electronic Control Unit;

D. Electronic Control Unit: Responsible for receiving signals from sensors and calculating the required motor assistance based on these signals as well as other parameters such as vehicle speed. The ECU also monitors the system’s operating status and performs fault diagnosis and handling when necessary;

E. Actuator: According to the ECU’s instructions, the actuator transmits the torque generated by the motor to the wheel’s steering knuckle, achieving the vehicle’s steering;

F. Power Supply System: Provides the necessary electrical power for the steering wheel motor and its control system, and it is usually from the vehicle’s battery.

The Working Principle of the Power Steering Motor

Firstly, when the driver turns the steering wheel, the torque sensor detects the torque applied by the driver. The torque sensor then sends the detected torque signal to the ECU. Subsequently, the ECU calculates the required motor assistance based on the received torque signal and vehicle speed signal, as well as the preset assistance curve. Finally, the assist torque acts on the steering system, helping the driver overcome steering resistance and achieve vehicle steering. The system adjusts the motor’s assist output based on actual steering conditions and road surface conditions, ensuring the precision and comfort of steering operations.

The Functions of the Power Steering Motor

1. Providing Steering Assistance: The primary role of the steering wheel motor is to provide steering assistance for drivers through the EPS system, making steering easier;

2. Enhancing Driver Comfort: By reducing the effort required by the driver during steering, the steering wheel motor can enhance driving comfort;

3. Improving Driving Safety: In emergency situations, the steering wheel motor can quickly respond to the driver’s operations, providing necessary assistance to help the driver better control the vehicle, thus ensuring driving safety;

4. Memory Functions: Some auto’s steering wheel motors also have a memory function that can retain the driver’s optimal steering wheel angle for ease of use;

5. Responding to Vehicle Speed Changes: The steering wheel motor’s assist output can be adjusted according to the vehicle speed, reducing assistance at high speeds to improve vehicle stability, and increasing assistance at low speeds to reduce the driver’s burden;

...

The Technical Challenges in the Design and Production of Power Steering Motors

1. Safety and Reliability: In steer-by-wire systems, there is no direct mechanical connection between the steering wheel and the steering wheel, making the system's safety and reliability a core challenge in design;

2. Force Feedback Mechanism: To simulate the road feel of traditional steering systems, the steering wheel motor needs to integrate a force feedback motor. Designing a force feedback system that accurately simulates road feel while ensuring system stability and responsiveness is challenging;

3. Control algorithms: The steering wheel motor requires precise control algorithms to manage the motor's output to meet different driving conditions and requirements;

4. Cost control: How to control production costs while ensuring high quality and safety is a challenging technical issue;

5. Energy-saving: While striving to improve motor performance, responding to environmental policies and achieving energy efficiency and low loss is a significant challenge.

The Development Trends of the Power Steering Motor

With technological advancements and increasing market demand, the development of power steering motors will move towards higher levels of electrification, intelligence, safety, and reliability.

1. Steer-by-wire Technology: With the advancement of unmanned driving technology, steer-by-wire systems are becoming a new technological trend. Compared to traditional steering systems, steer-by-wire systems completely eliminate the mechanical connection between the steering wheel and the steering mechanism, with steering operations entirely controlled electronically. This system not only improves the design flexibility of vehicles but also facilitates the integration of autonomous driving technology;

2. Intelligence: To meet the growing needs of humans, power steering motors are also continuously improving their level of intelligence, ensuring safety and convenience while increasing efficiency;

3. System integration and modularization: To simplify the production process and reduce manufacturing costs, the system integration and modular design of power steering motors will become a development trend.

The Global Market Trend Forecast of the Power Steering Motors

With global attention to reducing carbon emissions and the pursuit of energy-saving and environmental protection, the demand for electric and hybrid vehicles is continuously growing. These vehicles are usually equipped with EPS systems, thus increasing the demand for power steering motors.

Asia-Pacific Region

It is predicted that the Asia-Pacific region will continue to dominate the power steering motor market, holding the largest market share. Among them, it is estimated that the Chinese electric power steering market will have a compound annual growth rate of about 12.95% from 2020 to 2025.

European Region

Although European car manufacturers entered the electric vehicle market slightly later, they have maintained rapid growth, and many European countries have introduced supportive policies, also holding a significant market share.

North American Region

The North American market is expected to continue to grow due to the increasing demand for new energy vehicles and government support policies for clean energy vehicles.

If you would like to know more information about power steering motors or are interested in manufacturing equipment, please feel free to contact Shenzhen HONEST. We look forward to hearing from you.