The structure of an inductor:

An inductor consists of a magnetic core and a coil. The magnetic core is the core part of the inductor, which determines the performance of the inductor. Commonly used magnetic core materials include ferrite, manganese-zinc ferrite, iron powder core, neodymium-iron-boron, and so on. The core is another important part of the inductor, which determines the capacity of the inductor. Commonly used wire materials include enameled wire, bare copper wire, and so on.

The working principle of inductors:

When current flows through a wire, a magnetic field is created around the wire. When the wire is wound into a coil, the magnetic field is concentrated inside the coil. If the core is enclosed in a core, the magnetic field will be even more concentrated.

According to the principle of electromagnetic induction, when a current is passed through a coil, an induced electromotive force is generated inside the coil. The direction of the induced electromotive force is opposite to the direction of the current. Therefore, the current flowing through an inductor is hindered by the induced electromotive force.

Inductance has a greater blocking effect on alternating current than direct current. This is because the direction of the alternating current will continue to change, and the induced electromotive force will also continue to change, thus creating a greater obstruction to the current.

The main characteristic parameters of inductors are:

1. Inductance: it is the main characteristic parameter of an inductor and indicates the ability of an inductor to store magnetic energy. The larger the inductance, the more magnetic energy the inductor can store.

2. Rated current: it is the maximum current that the inductor can withstand. Exceeding the rated current will cause damage to this inductor.

3. Loss: the inductor will produce losses during operation, mainly including copper losses and iron losses. Copper losses are due to the current flowing in the coil and iron losses are due to the magnetic core.

4. Frequency characteristics: the characteristics of an inductor are related to frequency. At low frequencies, the impedance of the inductor is large, and at high frequencies, the impedance of the inductor is small.

The advantages of HONEST Automation’s equipment:

1. The machine has high precision and stable and reliable operation;

2. The machine is compact and occupies a small area;

3. The machine has a high degree of automation, and key parts are processed independently using precision equipment.

The following is some information about HONEST Automation Inductor Winding Machines:

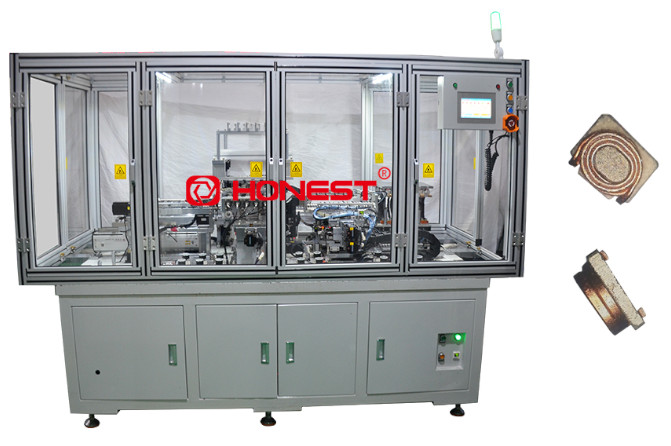

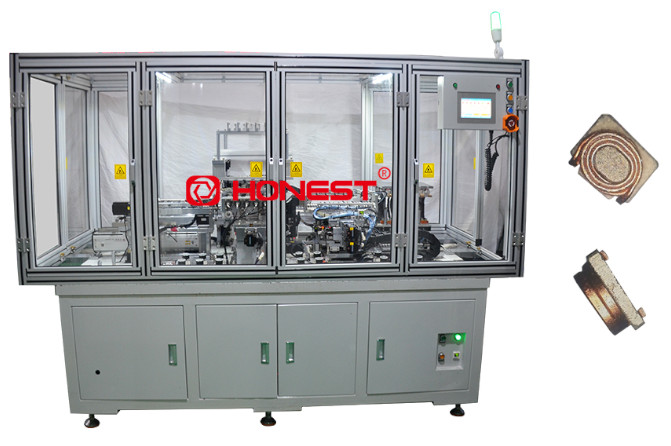

1. Common Mode Inductor Winding Equipment

Introduction: The common mode inductor winding machine process includes automatic loading, winding, spot welding, and blanking. It can complete 2P, 4P, 6P, 8P, and other specifications of pad cores, realize the integration of winding spot welding, is suitable for 5819, 5817, 4532, and 3216 size chip inductors, single and double wires, can be switched freely, it can be switched at will according to customer requirements.

Equipment Parameters:

A. Production Efficiency: up to 2000 PCS/H;

B. Spindle Speed: 1500MAX;

C. Distance Between Shafts: 40MM;

D. Voltage: 380V;

E. Air pressure: 0.5-0.7MPa;

F. Applicable Wire Diameter: 0.02-0.12.

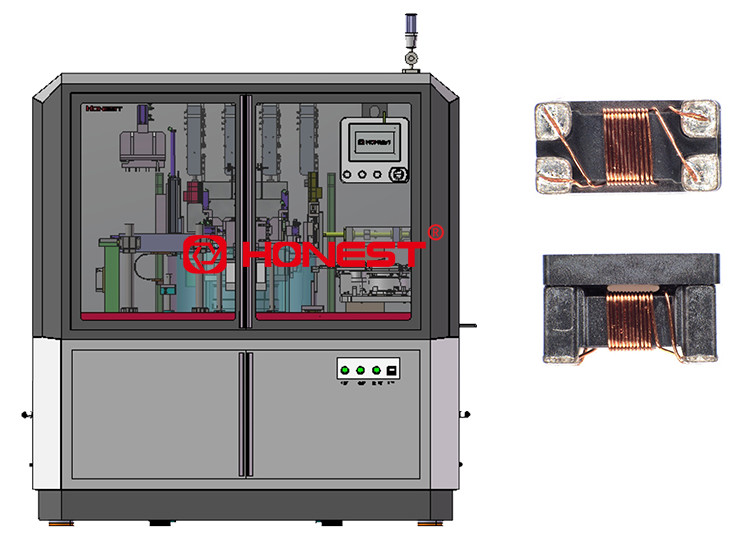

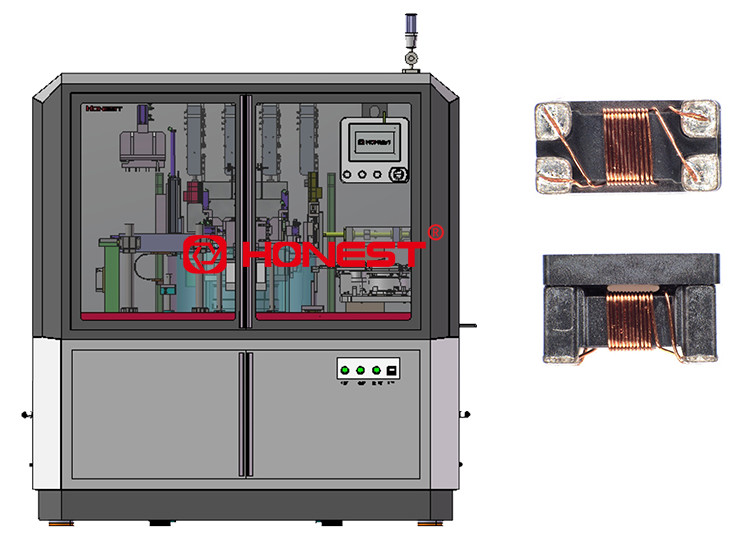

2. Tcore Integrated Inductor Winding Machine

Introduction: The process flow of the Tcore Integrated Inductor Winding Machine includes:

Magnetic core loading: Magnetic core Tcore vibration plate loading;

Winding: Flat wire is wound onto the magnetic core, using a bifilar winding technique, with hot air applied for self-adhesion as winding proceeds;

Wire Management: Arrange the wire neatly, trim any excess tail wire, and then solder it securely to the magnetic core;

Unloading: Discharge the product according to customer requirements.

Equipment Parameters:

A. Production Efficiency:0.4s/pcs;

B. Yield rate:>99%;

C. Operating rate:>95%;

D. Required number of operators:0.5 operators required;

E. Voltage: AC three-phase 380V;

F. Air pressure 0.4-0.6MPa

G. Power: 4kw

H. Dimension 2500(L)*1500(W)*1900(H)mm

3. NR SMD Inductor Fully Automatic Winding Machine

Introduction: The Surface-Mount Device (SMD) Inductor Fully Automatic Winding Machine automatically performs tasks such as feeding, winding, and tinning. It offers high efficiency, with multiple axes winding simultaneously, achieving a production capacity of 5000~6000 per hour. The product is mainly used in fields such as multifunctional mobile phones, LED lighting, communication equipment, portable and personal navigation systems, multimedia devices, and more.

Equipment Parameters:

A. production Efficiency: 5000-6000 per hour;

B. Product specification: 201610,length2.0-width, thickness 1.0;

C. Applicable wire diameter: 0.05-0.16mm;

D. Winding method: a multi-axis winding;

E. Wire end treatment: fixed point cutting;

F. Power supply: 220V,30A

G. Air pressure:5-7kgf

H. Power:5kw

I. Physical dimensions:1600(L)*1700(W)*2000(H)mm

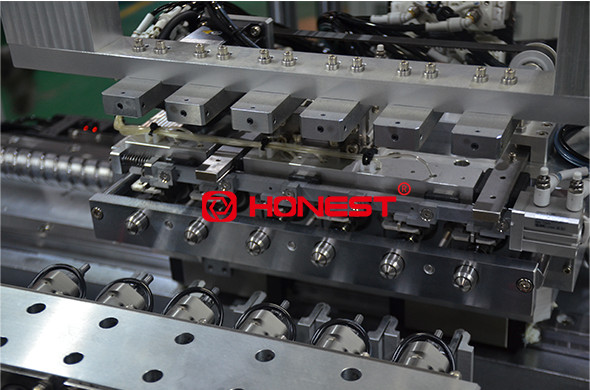

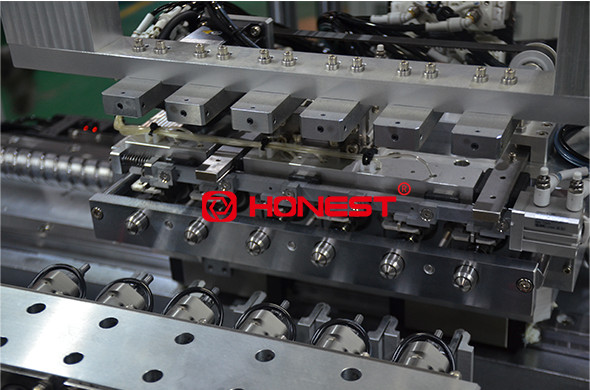

4. Common Mode Choke Four-Axis Winding Machine

Introduction: The main processes of the four-axis common mode inductor automatic winding equipment include loading, winding, welding, and unloading. The equipment can wind multiple axes simultaneously, achieving an efficiency of 1300-1500 pcs per hour.

Equipment Parameters:

A. Production Efficiency: 1300-1500 pcs per hour;

B. Scope of Application: common mode 2012 4532 3216 and other full series products;

C. Applicable Wire Diameter: 0.02-0.11;

D. Winding Method: spindle winding;

E. Loading and Unloading Methods: magnetic core vibrating tray for fully automatic loading, with bulk finished products being discharged;

F. Power supply: 220,30A;

G. Air pressure:5-7kgf

If you are interested in choke winding machine or need automated equipment, please consult us for free customized solutions and quotes. We are glad to serve you.