The definition of the stator:

The stator is the fixed part of the motor, usually located on the outside of the motor, opposite the rotor. The main function of the stator is to generate a rotating magnetic field, while the main function of the rotor is to be cut by magnetic lines of force in the rotating magnetic field to generate current.

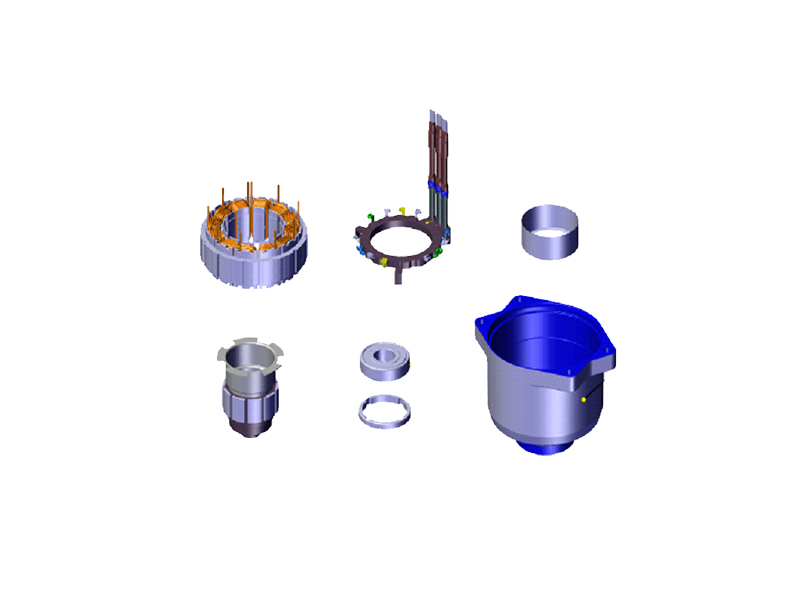

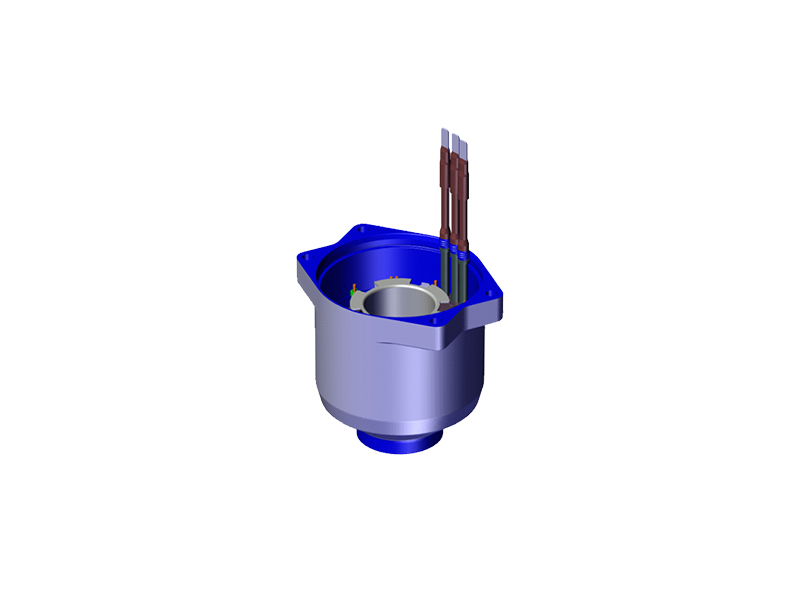

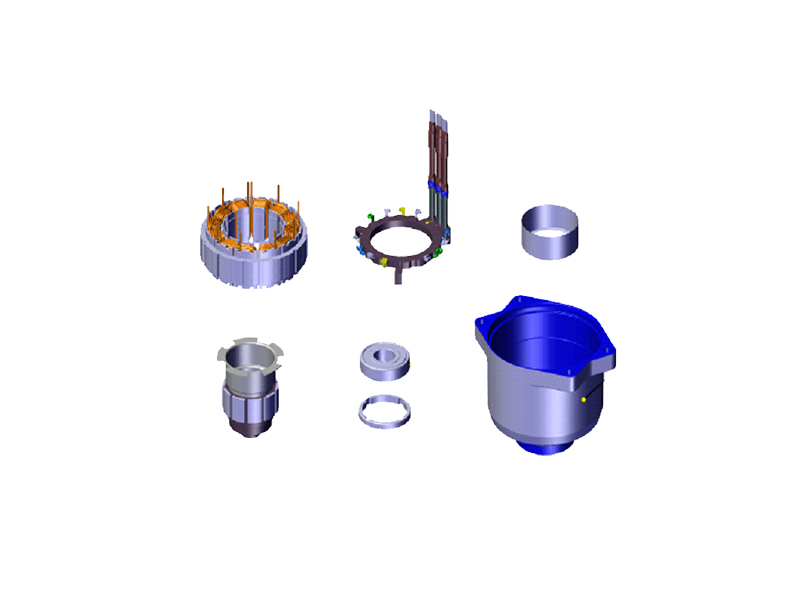

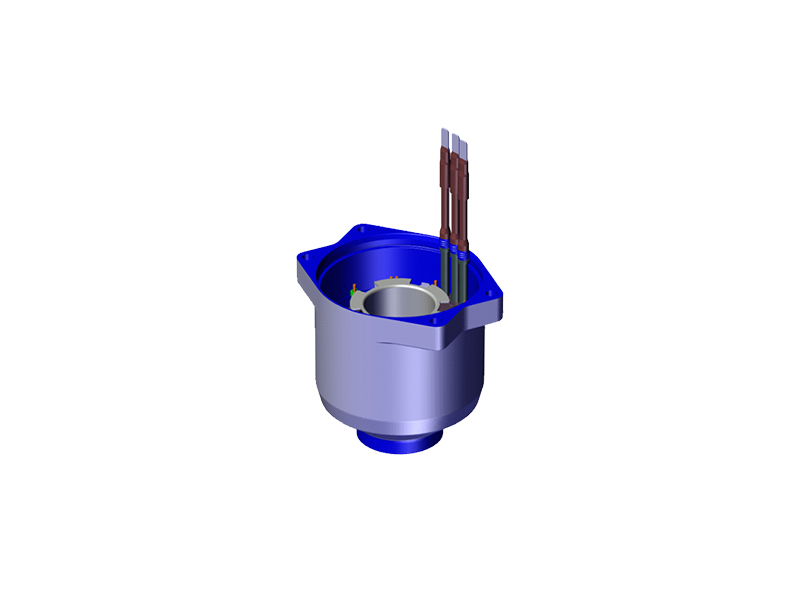

The components of the stator:

1. The stator core is the main structure of the stator, which is made of laminated thin silicon steel sheets to reduce tape loss and eddy current loss;

2. The stator winding is the main component of the stator and is made of wires. It can be divided into two types: concentrated winding and distributed winding. The former is usually used for low-power motors, while distributed winding is usually used for high-power motors;

3. The casing is the outer and winding, usually made of metal materials. Its role is to provide mechanical support, protect internal components, and help dissipate heat;

4. Insulating materials: to prevent current leakage and protect the stator winding, insulating materials are used between various components of the stator, as well as between the stator winding and the iron core;

5. Cooling system: in some large or high-power motors, the stator may include a cooling system to help dissipate the heat generated during operation;

6. End cover: it is a component installed at both ends of the stator housing. It is used to close the motor, protect internal components, and sometimes is used to install other components such as bearings.

The stator in motors can be divided into the following types:

1. Single-phase Stator: usually used in single-phase motors, consisting of two-phase winding;

2. Three-phase Stator: it is usually used in three-phase motors and composed of three-phase winding;

3. Synchronous Stator: it is usually used in synchronous motors, the number of winding and rotor magnetic poles is equal;

4. Asynchronous Stator: it is usually used in asynchronous motors, the number of winding and rotor magnetic poles is not equal.

The performance of the stator has a great influence on the motor’s performance.

The thinner the stator core, the smaller the magnetic loss and the higher the efficiency of the motor. The higher the slot fill ratio of the stator winding, the higher the slot fill ratio of the stator winding, the higher the power density of the motor. The higher the strength of the base, the better the operating stability of the motor.

The working principle of the stator:

In an AC motor, the stator winding is connected to the AC power supply to generate a rotating magnetic field, which interacts with the conductors in the rotor to cause the rotor to generate rotational power;

In a DC motor, the magnetic field generated by the stator is usually static. Still, through the action of the commutator, the direction of the current on the rotor can be periodically changed, thereby generating continuous rotational power.

The main function of the stator:

1. Generation of Rotating Magnetic Field: when the stator winding is supplied with alternating current, an alternating magnetic field will be generated. Due to the structure of the stator winding, the alternating magnetic field forms a rotating magnetic field is the fundamental reason why the motor generates power;

2. Induced Current: in a generator, the stator winding cuts the magnetic lines of force in the rotating magnetic field, which induces a current in the stator winding. Induced current is the fundamental reason why generators produce electrical energy;

3. Supporting the Rotor: the rotor will be installed in the slot of the stator core, and the stator core plays the role of supporting the rotor.

The advantages of HONEST’s Equipment:

1. Production data can be queried by scanning the product QR code;

2. Adopt a production line data traceability system;

3. The equipment is equipped with special safety gratings, safety door locks, and so on, for personal safety protection;

4. The equipment control system mainly consists of human-machine interface, programmable controller PLC, industrial computer, and so on;

5. Use a visual inspection system to inspect whether insulation is installed.

If you are interested in the Stator Assembly Line, please contact us at your times.