Hub motor

The hub motor is designed to integrate the car’s "power system, transmission system, and braking system”.

The advantages of the hub motor:

A. Omitting a lot of transmission components to make the vehicle structure simpler;

B. A variety of complex driving methods can be realized. Since the hub motor has the characteristic of independent driving of a single wheel, it can be relatively easily implemented whether it is front-wheel drive, rear-wheel drive, or four-wheel drive. Full-time four-wheel drive is very easy to implement on a vehicle driven by a hub motor;

C. Facilitate the adoption of various new energy vehicle technologies.

Whether it is a pure electric vehicle, a fuel cell electric vehicle, or an extended-range electric vehicle, a hub motor can be used as the main driving force; even for a hybrid model, a hub motor can be used as a boost when starting or accelerating rapidly, which can be said to be one machine for multiple purposes. At the same time, many technologies of new energy vehicles, such as braking energy recovery, can also be easily implemented on hub-motor-driven models.

The disadvantages of the hub motor:

A. Although the quality of the entire vehicle has been greatly improved, which will have a huge impact on the vehicle’s control, comfort, and suspension reliability;

B. The cost of four-wheel hub motors with high conversion efficiency and lightweight remains high;

C. Reliability issue: putting a precision motor on the hub will lead to fault problems caused by long-term severe up and down vibration and harsh working environment, and the maintenance cost will be high;

D. Braking heat and energy consumption issue, the motor itself is in the heat, due to the increase in the mass under the spring, braking pressure is greater, and the heat is also greater, so that the concentration of heat on the braking performance requirements.

The applications of hub motor drive technology:

A. Integrated electric systems developed by R&D teams represented by tire manufacturers or auto parts manufacturers;

B. Electric vehicles jointly developed by vehicle manufacturers and hub motor drive system manufacturers.

Mid-drive Motor

Definition: in electric bicycles and motorbikes, it refers to the motor installed near the center of the vehicle frame. The motor in this layout is connected to the bicycle’s gear system via a chain, belt, or gear mechanism to provide power to either the rear or front wheel.

The advantages of the mid-drive motor:

A. Since the motor is located in the center of the vehicle, this helps the weight to be evenly distributed on the front and rear wheels, thereby improving the vehicle’s balance and handling;

B. The mid-drive motor can make use of the bicycle’s transmission system, allowing the motor to work within the optimal speed range, improving overall energy efficiency and possibly increasing the service life of the motor and battery;

C. Compared with hub motors, mid-drive motors can more effectively utilize the gear ratio of the transmission when facing steep slopes, providing greater torque and thus better climbing performance;

D. The design of the mid-drive motor makes tire replacement and repair more convenient;

E. The mid-drive motor makes less noise and provides a better riding experience.

The disadvantages of the mid-drive motor:

A. The structure of the mid-drive motor is complex and the installation cost is higher than that of the hub motor;

B. Since the electric assist system will increase the load on the chain and gears, these components may wear out faster than on traditional bicycles;

C. The mid-drive motor usually requires a specially designed frame to adapt to the motor, and not all bicycles can be easily converted into electric bicycles.

The mid-drive motors are suitable for the following types of e-bikes:

1. Electric bicycles that require strong power, such as mountain electric bicycles, electric mopeds, and so on;

2. Electric bicycles that require good handling, such as urban electric bicycles.

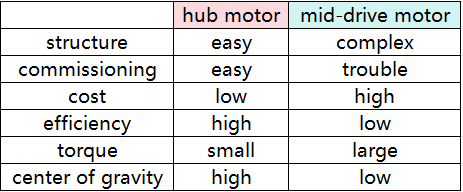

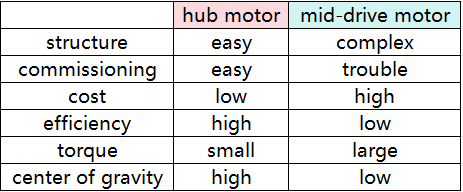

The hub motor vs the mid-drive motor

Similarities:

A. Electric assistance: both motors are designed to provide electric assistance to make riding easier;

B. Environmental protection: as electric drive methods, they can reduce dependence on fossil fuels and carbon emissions;

C. Control method: whether it is a hub motor or an electric bicycle with a mid-drive motor, it is generally equipped with a controller and a battery. The user can adjust the power output of the motor through the controller;

Differences:

A. Installation location: the hub motor is installed in the front or rear wheel hub of the bike; the mid-drive motor is debugged in the center of the bike chassis, usually on the axis of the pedal;

B. Power transmission method: the hub motor directly drives the wheel hub, and the power transmission is simple and direct; the mid-drive motor transmits power through the chain and the bicycle’s gear transmission system;

C. Weight distribution: the weight added by the hub motor is concentrated on the wheel hub, which may affect the handling and suspension response; the weight of the mid-drive motor is more concentrated in the center of the vehicle, which is beneficial to weight balance and riding stability;

D. Climbing performance: the hub motors are usually suitable for flat roads and urban commuting, but have weak climbing capabilities; the mid-drive motors are good at coping with complex terrain, and can provide greater torque and better climbing performance through the transmission;

E. Maintenance and repair: when replacing tires or repairing wheel hub motors, you need to deal with the entire hub assembly, which is a bit complicated; mid-drive motors may wear more frequently due to chain and gear wear, but tire replacement and maintenance are relatively simple;

F. Riding experience: hub motors may affect the acceleration and braking of the bicycle due to the extra weight or the hub; the mid-drive motor has a more natural riding feel because its power transmission method is similar to that of a traditional bicycle;

G. Cost: hub motors are usually cheaper than mid-drive motors.

If you have some interest in hub motor winding or need hub motor winding assembly equipment, please don't forget to contact us at your times. We will provide customized solutions and quotes to meet your needs.