As the global electric two-wheeler market continues to surge, manufacturers face increasing pressure to innovate in motor design, production efficiency, and quality control. One of the most critical components of an electric motorcycle is the wheel hub motor, and its stator winding process directly affects motor performance, reliability, and manufacturing cost.

To meet this growing demand, HONEST Automation has developed a new-generation stator winding machine specifically designed for e-motorcycle wheel hub motors. This machine reflects our deep expertise in motor automation and our strategic shift toward serving overseas customers with localized, customizable, and intelligent production solutions.

The Growing Demand for E-Motorcycle Hub Motors

Electric motorcycles (e-motorcycles) are gaining traction worldwide due to rising fuel costs, stricter emissions regulations, and rapid urbanization. According to global market data, Southeast Asia, Latin America, India, and parts of Eastern Europe are experiencing double-digit growth in electric two-wheeler adoption.

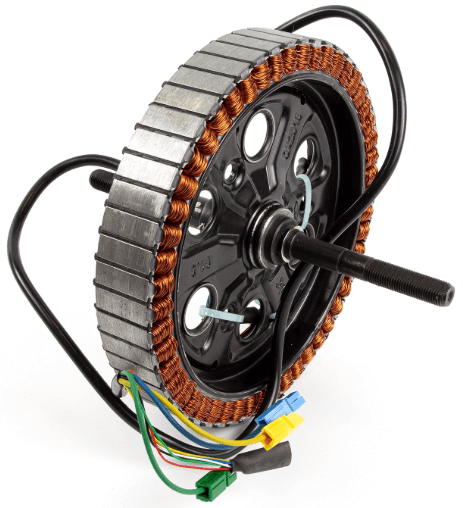

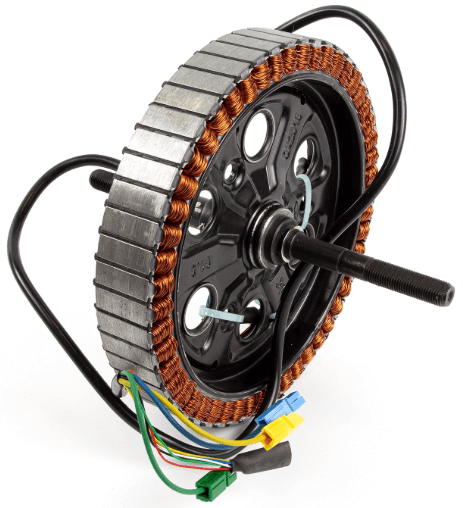

In these markets, hub motors are favored for their simplicity, integrated structure, and cost-effectiveness. However, their compact stator design—with high slot density and tight winding spaces—creates significant production challenges, especially in achieving high copper fill rates, precision wire placement, and stable winding quality.

HONEST’s R&D Breakthrough: New Flyer-Type Winding Solution

Our newly developed flyer stator winding machine was born out of intensive R&D efforts aimed at addressing the specific pain points of hub motor stator production.

Tailored for Compact, High-Slot-Count Stators

Electric motorcycle hub motors often feature multi-slot stators with complex slot geometries. Our machine’s flyer mechanism is optimized to perform clean and consistent layer winding, reducing common issues such as wire overlap, insulation damage, and uneven fill.

Adjustable Fixture System

Recognizing the variability of hub motor designs between regions and brands, we’ve designed a modular fixture system that can be easily adapted to different stator sizes and shapes, supporting flexible production needs and fast model changeover.

Semi-Automated Wire Handling

Key operations—such as wire feeding, winding start point fixing, and wire cutting—are semi-automated, reducing labor dependency while maintaining operator visibility and control.

Digital Parameter Management

Via a touch-screen HMI interface, users can set and store winding parameters such as turn number, pitch, speed, and direction. This enables faster setup and better process control, especially useful for small-batch trial production and prototyping.

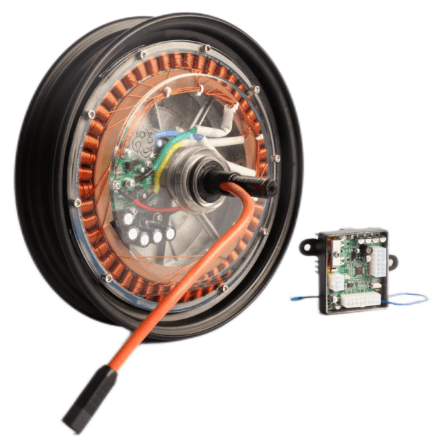

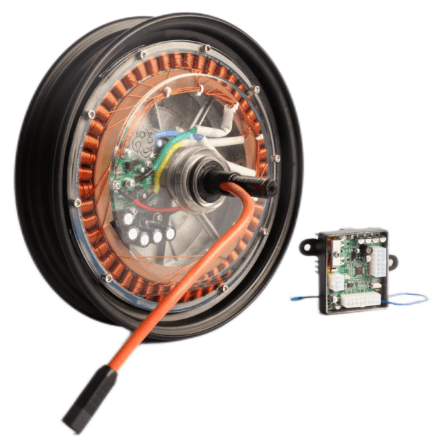

Future-Ready for Full Automation

This machine is positioned as a scalable base platform, with potential upgrades for robotic loading/unloading, automatic wire termination, and integration with MES/traceability systems.

Application Scenarios and Benefits for E-Motorcycle Manufacturers

Whether you're an e-motorcycle OEM or a motor supplier, the benefits of adopting HONEST’s new wheel hub motor stator winding machine include:

Improved winding consistency and repeatability, even for high-turn-count coils

Reduced production time and human errors versus traditional manual winding

Shorter setup time for different models, supporting multi-variety production

Potential for integration into smart production lines for large-scale manufacturing

This solution is particularly suitable for companies looking to transition from labor-intensive winding methods to semi-automated or automated systems as part of their smart factory strategy.

Co-Innovating with Global Motor Manufacturers

The HONEST Wheel Hub Motor Winding Machine for E-Motorcycles is more than just equipment—it’s a modular, scalable, and market-oriented solution for the next generation of motor manufacturing.

If you're a motor engineer seeking precision winding, a plant manager considering automation, or a procurement officer planning capacity expansion, we invite you to partner with HONEST Automation during this early rollout phase.

Contact our international team today to schedule a technical consultation, request detailed machine schemes, to improve your company's production efficiency and overall competitiveness

Let’s wind the future of e-mobility—together.