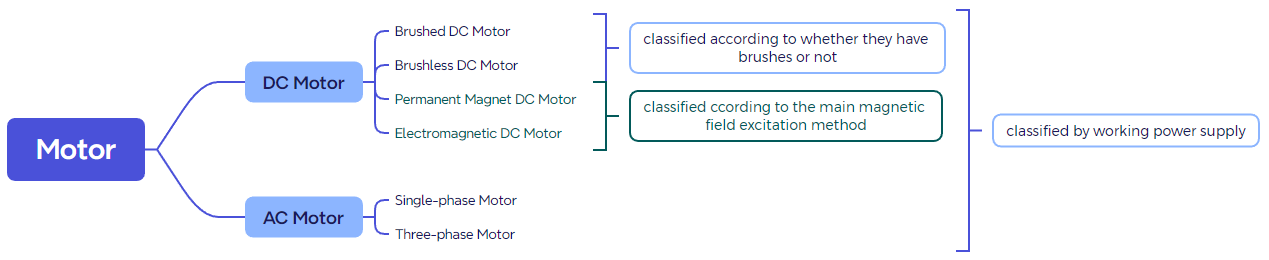

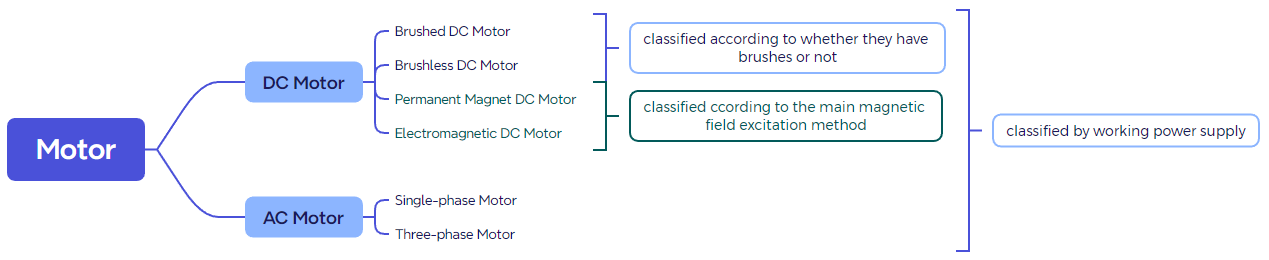

Classification of motors:

There are several classification methods for motors. First, according to the type of working power supply, they can be divided into the DC motor and the AC motor. Secondly, the AC motor can be divided into single-phase AC motor and three-phase AC motor; the DC motor can be divided into brushless DC motor and brushed DC motor according to whether it has a brush or not. Last but not least, according to the main magnetic field excitation method, they can be divided into permanent magnet DC motors and electromagnetic DC motors.

In a previous article in the product articles section of our website, we talked in detail about the brushless motor, so this article will focus on the brushed motor and the difference between brushed and brushless motors.

The brushed direct current motor’s details are as follows:

What is the brushed motor?

The brushed motor is a rotating motor that contains a brush device and converts electrical energy into mechanical energy or mechanical energy into electrical energy.

What is the brushed motor’s structure?

The brushed motor is mainly composed of a rotor, a stator, a carbon brush, and a commutator.

What are the brushed motor’s features:

The brushed motor is the basis of all motors, it has the characteristics of fast starting, timely braking, smooth speed regulation in a wide range, and a relatively simple control circuit.

The advantages of the brushed DC motor:

1. Fast response, high starting torque, and smooth shifting;

2. Excellent low-speed torque performance and large torque;

3. Higher reliability due to the avoidance of the impact of sensor interference and electronic parts failure;

4. The structure is relatively simple and the manufacturing and use costs are low.

The disadvantages of the brushed DC motor:

1. There is friction between the brushes and the commutator, resulting in reduced efficiency, increased noise, easy heat generation, and short life of the brushed motor;

2. Because of its large resistance, the output power is small and the efficiency is low;

3. The friction between the brushes and the commutator will cause sparks to interfere with nearby electronic components and signals.

How brushed DC motor works:

When the motor is working, the coil and commutator rotate, but the magnets and carbon brushes do not rotate. The alternating changes in the direction of the coil current are completed by the commutator and brushes that rotate with the motor.

A brushed motor is composed of two parts: a stator and a rotor. The stator has magnetic poles, and the rotor has winding. After power is applied, a magnetic field is also formed on the rotor. There is a magnetic pole between the stator and rotor poles. The included angle causes the motor to rotate due to the mutual attraction of the stator and rotor magnetic fields. Changing the brush's position can change the angle between the stator and rotor magnetic poles’ direction, thereby changing the rotation direction of the motor.

What is the working process of the brushed motor?

First of all, current flows from the external supply through the brushes and into the winding. Secondly, the winding creates a magnetic field, which then interacts with the stator magnetic field to produce a rotational torque. lastly, the rotor starts to spin and the brush will move as the rotor changes the direction of current in the winding.

This series of processes is repeated to keep the motor spinning.

What are the brushed motor’s precautions?

First of all, it is necessary to check its winding’s DC resistance, insulation resistance, brush wear, and so on, before using equipment that has not been used for a long time or is newly used.

Secondly, during use, the motor should be operated and used correctly to avoid overloading;

In addition, in terms of daily maintenance of the motor, there are some points as follows:

1. Remove dust inside and outside the motor to ensure its heat dissipation performance is intact;

2. Check whether the motor wiring ends are tight and reliable;

3. Check the bearings of the motor, clean and replace the lubricating oil;

4. Check the wear of the brushes and whether the pressure is too high or too low and other situations;

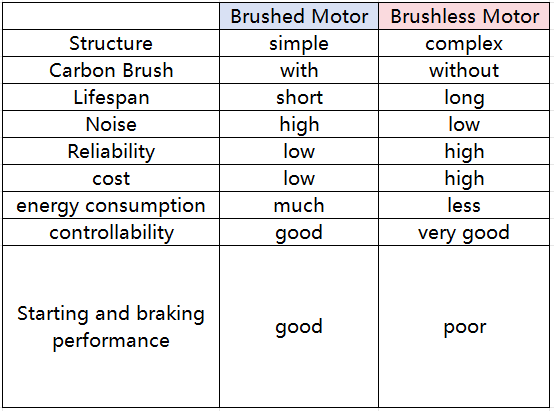

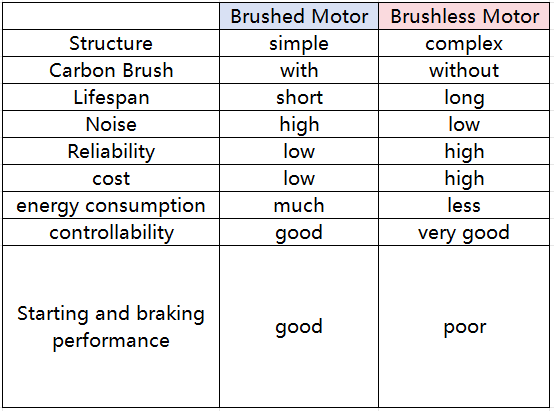

The comparison between brushed and brushless motor:

1. Exterior:

First of all, the most intuitive difference is whether there is a carbon brush or not.

2. Scope of application:

Brushed motor: Usually power equipment uses brushed motors, such as hair dryers, factory motors, household range hoods, and so on.

Brushless motor: it is usually used on equipment with relatively high control requirements and high speeds, such as model aircraft, precision instruments, and other equipment that have strict motor speed control and high speeds.

3. Service life:

Brushed motor: Usually the continuous working life of a brushed motor ranges from several hundred to more than one thousand hours, and when the use limit is reached, the carbon brushes need to be replaced, otherwise it will easily cause bearing wear.

Brushless motor: Usually the service life is tens of thousands of hours, but the service life of brushless motors also varies greatly due to different bearings.

4. Speed adjustment methods:

The brushed motor has variable voltage speed regulation; the brushless motor has variable frequency speed regulation.

5. Future maintenance:

The brushed motor needs to replace the carbon brushes. If the replacement is not timely, it will cause damage to the motor. The brushless motor has a very long service life, usually more than 10 times that of a brushed motor. However, if it is broken, the motor needs to be replaced.

6. Working principle:

For the brushed motor, the brushes and commutator control the coil current; for the brushless motor, an electronic controller controls the winding current.

Some other aspects are compared as shown in the figure below.

HONEST Automation’s advantages in manufacturing the brushed and brushless motor:

1. There are mature brushed motor and brushless motor stator and rotor assembly production lines, and there are customer cases that have been put into use;

2. The equipment is equipped with high-precision sensors, visual detection systems and alarm systems;

3. Equipped with complete safety protection devices to ensure the safe production of personnel;

4. The equipment solution technical team is composed of people with rich experience in the motor industry and can carry out non-standardized customization according to the different needs of customers.

If you are interested in brushed motor and bldc motor production line, please contact us now to get customized solutions and quotes.