1. What is Electric Power Steering (EPS)?

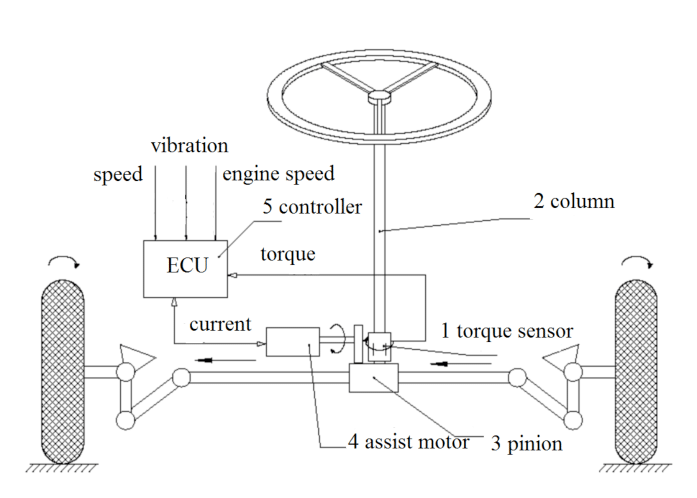

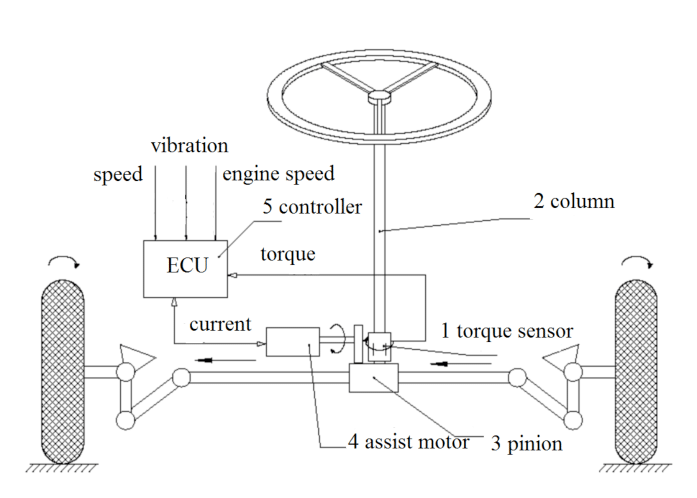

Electric Power Steering, referred to as EPS, is a power steering system that directly relies on an electric motor to provide auxiliary torque. Compared with the traditional Hydraulic Power Steering (HPS), the EPS system has many advantages. EPS is mainly composed of torque sensor, vehicle speed sensor, electric motor, reduction mechanism and electronic control unit (ECU).

2. Car Steering System

When the car is driving, the driver controls the steering wheel and uses a set of transmission mechanisms to deflect the steering wheel at a certain angle on the road to change its driving direction, ensuring the stable and safe normal driving of the car. A complete set of mechanisms (devices) that can deflect the steering wheels to achieve vehicle steering and change or maintain the vehicle's driving or reverse direction is called the vehicle steering system (Steering System). The function of the car steering system is that the driver controls the driving direction of the car and changes the driving direction of the car as needed by turning the steering wheel.

3. Development of Steering System

As an important subsystem of the automobile chassis system, the steering system's performance directly affects the vehicle's handling stability, driving comfort and driving safety. In order to continuously improve the performance of the steering system and meet the driver's requirements for low-speed steering lightness, high-speed steering feel and fuel economy, the automobile steering system has experienced (Manual Steering System (MS), Hydraulic Power Steering System ( HPS), Electro Hydraulic Power Steering System (EHPS) and (Electro Power Steering System (EPS).

4. Classification of EPS Motors

According to the installation position of the power-assisted motor, the EPS system can be roughly divided into 3 types: EPS (Column-EPS, C-EPS), EPS (Pinion-EPS, P-EPS) and EPS (Rack-EPS, R-EPS).

The motor and reducer of C-EPS are arranged on the steering column. The torque of the motor and the driver's torque jointly rotate the steering column and are transmitted to the rack through the intermediate shaft and pinion to achieve power assistance.

C-EPS is suitable for compact vehicles with small power assistance requirements; the motor is arranged close to the steering wheel, so it is easy to transmit vibration to the steering wheel.

The P-EPS motor is arranged at the meshing point of the pinion and rack. The system has a compact structure and is suitable for small cars with low power assistance requirements.

R-EPS motor refers to the rack-parallel type, where the motor is directly arranged on the rack. It is suitable for medium and large vehicles with large power assistance requirements. The motor power is generally transmitted to the rack through ball screws and belts.

5. EPS Motor Stator and Rotor Technology

EPS motor assembly process: wave pad inserting and oiling, stator and rotor components assembling, screwing, four claws pressing, the sensing magnet components pressing, performance testing, torque testing, etc.

EPS motor stator assembly process: insulating frame installation of tator core, winding, stator splicing, core pressing, laser welding, stator inner and outer diameter inspection, etc.

EPS motor rotor assembly process: shaft insertion into the iron core, end plate press-fitting, rotor cover press-fitting, rotor magnetization, end cap and rotor components press-fitting, etc.

6. Advantages of HONEST’s EPS Motor Stator and Rotor Assembly

A. HONEST Automation currently produces single-piece winding and double-wing EPS motor products for customers. We can also produce triple-winding and quadruple-winding products. Usually, the wire diameter of EPS motors is relatively large, and we have a self-made tensioner to achieve compatibility with products of different wire diameters.

B. The winding machine can be equipped with paint removing function and has a corresponding compatibility range. If it exceeds the compatibility range, just need to replace the paint-removing knife.

C. Some customers' multi-winding products may require to thread bushing. We have actual cases and can develop according to the characteristics of customers' products.

D. We can realize the iron core make up process of multi-winding products.

E. The high precision after welding of the stator can be controlled and tested to meet the actual needs of customers.

F. Bus assembly can realize automated assembly.

At present, HONEST Automation has provided successful cases of EPS motor automated assembly equipment for well-known automobile manufacturers and leading motor companies. We can provide customized semi-automatic and fully-automatic assembly solutions according to customer requirements, including stator sections, rotor sections and EPS motor assembly sections.

If you are looking for EPS motor assembly line manufacturers, please contact us online.