What is an oil pump motor?

Definition:

An oil pump is a device that uses mechanical energy to transport liquid from a low-pressure place to a high-pressure place. The oil pump motor refers to the motor that drives the oil pump to work. Oil pump motor is an important part of the hydraulic system, its performance directly affects the performance of the hydraulic system.

What is the function of the oil pump motor?

1. Increase oil pressure in automotive lubrication;

2. Force the oil to be sent to all friction surfaces of the engine;

3. The oil pump can store a certain amount of engine oil.

The classification of oil pump motors:

Oil pump motors can be divided into gear oil pumps and rotor oil pumps, the details are as follows:

One is the gear oil pump

Structure:

It is composed of a driving shaft, a driving gear, a driven shaft, a driven gear and a pump body. It has two arrangements: external meshing and internal meshing. Two gears with the same number of teeth mesh with each other and are installed in the pump body. The radial and end clearance between the gears and the pump body is very small. The driving shaft is connected to the driving gear by a key, and the driven gear is sleeved on the driven shaft.

Work principle:

The driving gear on the camshaft drives the transmission gear of the oil pump, making the driving gear rotate which is fixed on the driving gear shaft, thereby driving the driven gear to rotate in the opposite direction. Along the tooth gap and pump wall, engine oil is sent from the oil inlet chamber to the oil outlet chamber, so that low pressure is formed in the oil inlet chamber, which generates suction, sucking the oil in the oil shell into the oil chamber. As the main and driven wheels continue to rotate, the oil is continuously pressed to the oil outlet.

Advantages:

1. The structure is simple and easy to manufacture;

2. Reliable operation and long service life;

3. Pump oil pressure is high.

Disadvantages:

1. Its flow rate is relatively small;

2. Its noise is relatively loud.

Features:

1. It has good self-priming ability, simple structure, and reliable operation;

2. It is not allowed to close the outlet valve during operation, only the outlet valve can be controlled;

3. Suitable for conveying viscous, high-temperature, and high-pressure liquids.

The other is the rotor oil pump

Structure;

It is composed of a housing, an inner rotor, an outer rotor, and other parts. The inner rotor is fixed on the oil pump transmission shaft with a key or pin and is driven by the crankshaft gear. The inner rotor has 4-7 convex teeth, and the outer rotor has one more concave tooth than the inner rotor.

Work principle:

The tooth profile of the rotor ensures that when the rotor rotates to any angle, the tooth profile of each tooth of the inner and outer rotors can always make point contact with each other. In this way, four working cavities are formed between the inner and outer rotors. As the rotor rotates, the volumes of these four working cavities continuously change. In the cavity on one side of the oil inlet passage, due to the disengagement of the rotor, the volume gradually increases, creating a vacuum, and the oil is sucked in. The rotor continues to rotate, and the oil is brought to one side of the oil outlet. At this time, the rotor just enters the mesh, which reduces the volume of the cavity and increases the oil pressure. The oil is squeezed out from between the teeth and sent out through the oil outlet. As the rotor continues to rotate, oil is continuously sucked in and pressed out.

Advantages:

It has a compact structure, small dimensions, small mass, large oil suction vacuum, large pump oil volume, good oil supply uniformity, and low cost.

Disadvantage:

The sliding resistance is larger than that of the gear pump, and the power consumption is also larger.

Features:

1. There is no suction valve or discharge valve, its main working parts are the pump housing and rotor;

2. The rotor has no impact, high speed, compact structure, and small size;

3. The discharge pressure is small and can only transport a small amount of liquid;

4. Most rotor pumps rely on the lubrication of the liquid they deliver, so they are generally suitable for delivering liquids that are lubricating and do not contain solid particles;

5. The rotor pump discharges liquid intermittently, so the flow rate fluctuates greatly;

6. The friction between the rotors is small and the noise is small, so the service life is long.

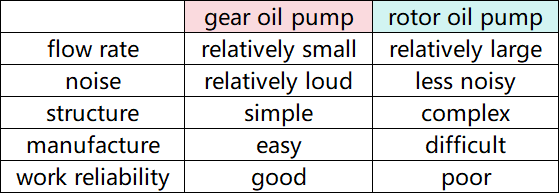

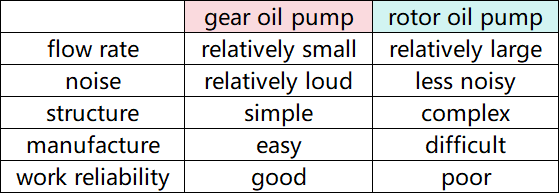

Gear Oil Pump VS Rotor Oil Pump

1. The flow rate of the gear oil pump is relatively small; and the rotor oil pump is relatively large;

2. The noise of the gear oil pump is relatively large; the rotor is relatively small;

3. The gear-type oil pump has a simple structure and is easy to manufacture; and the rotor-type oil pump has a complex structure and is difficult to manufacture;

4. The gear-type oil pump works reliably and has a long service life; the rotor-type oil pump has relatively poor working reliability;

5. The gear oil pump is the most widely used, mainly used in automobile engines, engineering machinery, agricultural machinery, and so on; and the rotor oil pump is mainly used in high-flow, low-noise applications, such as aircraft engines and large generator sets.

The advantages of HONEST Automation in oil pump motor assembly equipment:

We have rich experience in manufacturing oil pump motors and have successfully served many listed companies and leading enterprises in the industry. We are confident that we can manufacture automobile oil pump motor production line that meets customer standards. If you have any questions or needs, please feel free to contact us.