Definition and structure of water pump motor

Definition:

A water pump is a machine that transports liquid or pressurizes liquid. It transfers the mechanical energy of the prime mover or other external energy to the liquid to increase the energy of the liquid. It is mainly used to transport liquids including water, oil, acid and alkali liquids, emulsions, and liquid metals. A water pump motor refers to a device that converts electrical energy into mechanical energy and is used to drive a water pump.

Structure:

The water pump motor is mainly composed of stator, rotor, bearing, end cover, and other components. The stator is stationary and the rotor rotates. Bearings support the rotor. The end cap is used to seal and secure the water pump motor.

Classification:

One is the Electronic water pump motor:

A motor drives the electronic water pump, and the speed can be adjusted according to the actual needs of the engine, so the cooling effect is better.

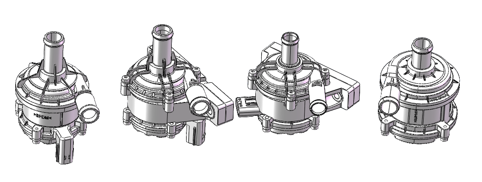

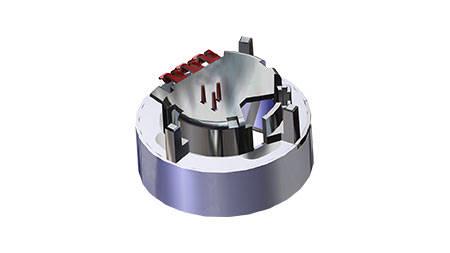

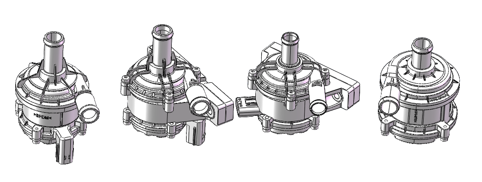

Structure:

The electronic water pump motor mainly consists of the following parts:

Motor: the power source that drives the water pump to rotate;

Pump body: the component that houses the impeller and bearings;

Impeller: the component that drives the flow of coolant;

Bearing: the component that supports the rotation of the impeller;

Seal: the component that prevents coolant leakage.

Working principle:

The working principles of electric water pump motors are mainly divided into two types:

One is a DC electronic water pump motor.

DC is input into the motor's rotor through the brush and commutator. The conductor in the rotor rotates under the force of the magnetic field, thereby driving the impeller of the water pump to rotate. During the rotation of the impeller, water is sucked into the water inlet and discharged from the water outlet under the action of centrifugal force.

The other is an AC electronic water pump motor.

AC generates a magnetic field through the stator winding of the motor, and the conductor in the rotor rotates under the force of the magnetic field, thereby driving the impeller of the water pump to rotate. During the rotation of the impeller, water is sucked into the water inlet and discharged from the water outlet under the action of centrifugal force.

Advantages:

1. Good cooling effect: The speed of the electronic water pump can be adjusted according to the actual needs of the engine, so the cooling effect will be better when the engine is running at low speed;

2. Small size and long service life: Electronic water pumps have no pulleys and transmission mechanisms, so they are smaller and have a longer service life;

Small noise: Electronic water pumps have no pulleys and transmission mechanisms, so they make less noise;

3. Energy saving: The control system of the electronic water pump motor can adjust the speed according to actual needs, so it can effectively reduce energy consumption;

4. Environmental protection: The control system of the electronic water pump motor can adjust the speed according to actual needs, so it can reduce the exhaust volume of the water pump, thereby reducing pollution;

5. Intelligent: The electronic water pump motor can be automatically controlled through the control system, thus improving the efficiency of the water pump.

Disadvantages:

1. High cost: The structure of the electronic water pump motor is more complex and requires the use of high-precision components, so the production cost is higher;

2. Low reliability: The control system of the electronic water pump motor is more complex and susceptible to inference, so the reliability is low. In addition, the control system of the electronic water pump motor also requires the use of a large number of electronic components, which are prone to aging and thus affect the reliability of the electronic water pump motor;

3. Maintenance is more difficult: The control system of the electronic water pump motor is relatively complex and requires maintenance by professionals.

The other is the mechanical water pump motor:

A mechanical water pump is a traditional automotive water pump driven by the engine crankshaft through a pulley.

Structure:

The mechanical water pump motor is mainly composed of two parts: the motor and the water pump. The motor is the component that provides power, and the water pump is the component that transports the liquid.

Working principle:

The working principle of a mechanical water pump motor is to drive the impeller of the water pump to rotate through the rotation of the motor, thereby transporting liquid from a low place to a high place. The rotation of the motor will be transmitted to the impeller of the water pump through the coupling. During the rotation of the impeller, the liquid will be sucked into the water inlet and discharged from the water outlet under the action of centrifugal force.

Advantages:

1. Simple structure: The mechanical water pump motor consists of two parts: a motor and a water pump. It has a simple structure and is easy to manufacture.

2. Low cost: The mechanical water pump motor has a simple structure and low manufacturing cost, so it has a high-cost performance.

3. High reliability: The mechanical water pump motor has a simple structure and no complex electronic components, so it has high reliability.

Disadvantages:

1. Low efficiency: The mechanical water pump motor has a simple structure and a fixed speed, so it has low efficiency and high energy consumption.

2. Loud noise: The mechanical water pump motor has a simple structure and no sound insulation measures, so it is noisy.

3. Difficulty in adjustment: The speed of the mechanical water pump motor is determined by the speed of the motor, so it is difficult to adjust.

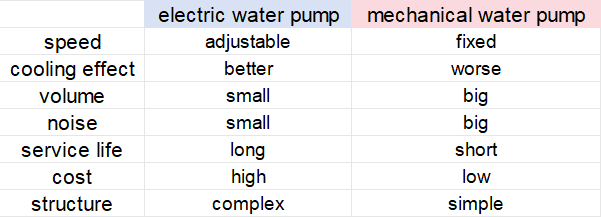

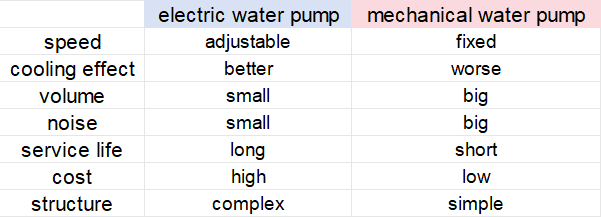

The electronic water pump water VS the mechanical water pump motor

1. Working principle difference

The automobile electronic water pump uses the circular motion of the automobile water pump motor and the mechanical device to make the diaphragm inside the water pump reciprocate, thereby compressing and stretching the air in the pump chamber (fixed volume). Under the action of the one-way valve, the air in the water pump flows out of the drain outlet. A positive pressure is formed at the water inlet; a vacuum is formed at the water suction port, thereby creating a pressure difference with the outside atmospheric pressure. Under the action of the pressure difference, water is forced into the water inlet and then discharged from the drain outlet. Under the action of the kinetic energy transmitted by the motor, water is continuously inhaled and discharged, forming a relatively stable flow rate.

The automobile mechanical water pump is a vehicle engine that drives the water pump bearing and impeller to rotate through a pulley. The coolant in the mechanical water pump is driven by the impeller to rotate together, and is thrown to the edge of the water pump housing under the action of centrifugal force, and then flows out from the water outlet or water pipe; The pressure at the center of the impeller is reduced because the coolant is thrown out. The coolant in the water tank is sucked into the impeller through the water pipe under the pressure difference between the water pump inlet and the center of the impeller, realizing a reciprocating circulation of the coolant.

2. Difference in structure and function

An electronic water pump motor is mainly composed of three parts: a fluid unit, a motor unit, and an electronic control unit. Compared with traditional mechanical water pump motors, electronic water pump motor has the advantages of high control accuracy and higher efficiency. Nowadays, most high-end cars and electric cars use electronic water pump motors to replace the original mechanical water pumps, widely used in automobile water circulation, cooling, or vehicle water supply systems.

Traditional mechanical water pumps work based on engine speed, which means that even in cold starts and low-load high-speed conditions where the flow demand is not high, it still requires a lot of power to drive, and the cooling energy is different from the actual demand of the engine, and it requires a lot of power to drive.

In this way, a large part of the cooling capacity of the mechanical water pump is wasted, which not only consumes a lot of additional driving capacity but also has a certain difference in cooling effect from the actual needs of the engine, which will cause the engine’s power and economy to decline. The electronic water pump can precisely control the flow according to the cooling device’s demand for coolant.

3. Difference in application fields

Most fuel vehicles use mechanical water pump motors, and some fuel vehicle engines have higher technical content and use electronic water pump motors. At present, most mechanical water pump motors still use traditional centrifugal water pumps. The engine crankshaft drives the impeller to rotate through the transmission belt. The coolant is thrown toward the water pump housing under the action of centrifugal force, forming a pressure difference between the center of the impeller and the water inlet of the water pump. The cooling hydraulic pressure in the radiator enters the center of the impeller. The electronic water pump is driven by a motor, generally using a brushless DC motor. The water pump shaft and the motor shaft are designed to be integrated. The built-in temperature control module controls the motor speed to adjust the coolant circulation speed.

The characteristics of electronic water pumps such as energy saving, emission reduction, high efficiency, environmental protection, and intelligent cooling determine that it is the general trend to replace mechanical water pumps. "Precision cooling" uses the minimum coolant flow to achieve optimal temperature distribution. The key to designing a precise cooling system is to select a matching cooling water pump to ensure that the heat dissipation capacity of the system can meet the operating temperature needs of critical areas of the engine at low speeds and high loads. For engines using an electric water pump cooling system, the coolant flow can be reduced by 40% throughout the entire operating speed range. Under the same configuration and cooling requirements, the energy consumption of an electric brushless DC water pump is only 16% of that of a mechanical water pump.

If you need an automotive water pump motor production line, welcome to consult online to get customized solutions and quotations. Shenzhen HONEST has many automotive water pumps fully automatic and semi-automatic motor assembly line cases.