1. Definition of EPS motor

EPS is the Electric Power Steering system. EPS is a steering system that can assist the driver in steering through an electric motor. Compared with the traditional hydraulic power steering system, there is no need to use hydraulic oil to provide steering assistance. Instead, electric drive is used to achieve steering assistance, so EPS has higher efficiency and better response speed.

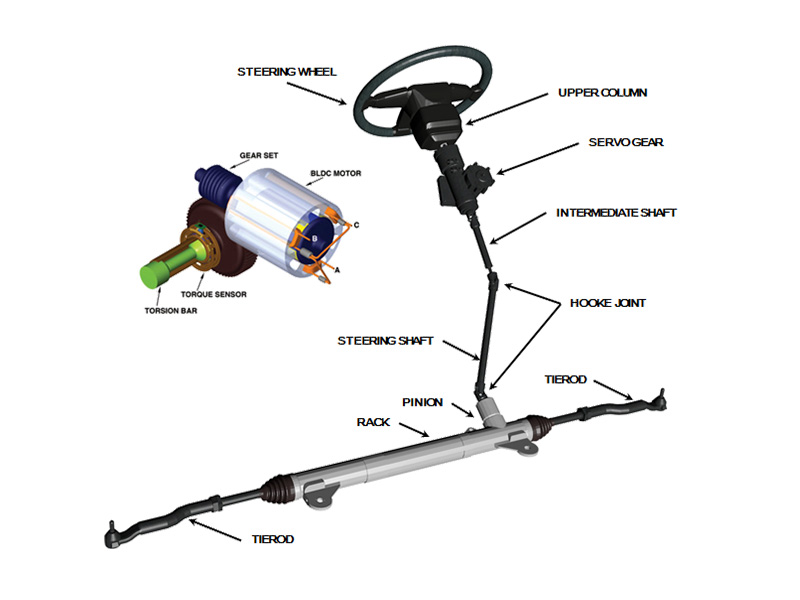

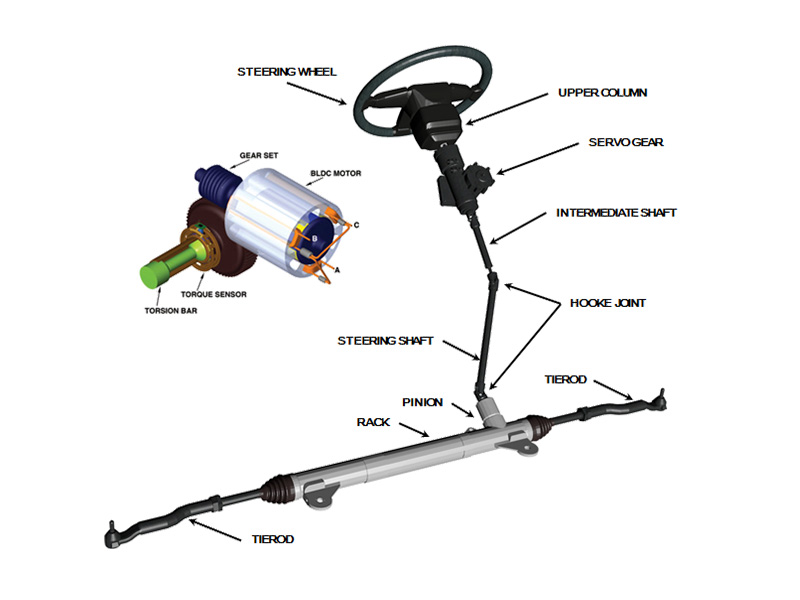

With the continuous development of technology, automobile steering systems are constantly updated and have become standard features of many automobile brands. EPS is mainly composed of automotive EPS motors, reduction gearboxes, controllers, and sensors. Among them, the motor is the core component of the EPS motor and adopts the design of brushless DC motor. A brushless motor means that there are no traditional carbon brushes on the motor rotor, and the forward and reverse flow of current is realized through an electronic commutator. In this way, the automotive EPS motor can reduce wear and noise, while also improving the life and efficiency of the EPS motor.

2. Working process of automobile EPS motor

When the car's EPS motor is working, the driver turns the steering wheel, and the sensor on the steering wheel will sense the steering angle and transmit this information to the controller. The controller will calculate the appropriate steering assist based on the driver's steering intention and the current status of the vehicle, and then use the motor to achieve the output of the steering assistance. At the same time, the controller will constantly monitor parameters such as the vehicle's speed, steering angle, and steering torque, so as to promptly adjust the magnitude and direction of the steering assistance when necessary.

The output torque size and direction of the automotive EPS motor can be adjusted through the controller. The controller can control the size and direction of the output torque by adjusting the size and direction of the motor's current. At the same time, the controller can also automatically adjust the size and direction of the steering assistance based on the vehicle's speed and steering angle, so that the driver can get appropriate steering assistance in different driving situations.

3. Advantages of EPS motor

A. Save fuel: The EPS motor uses battery power supply and does not directly consume engine fuel, which can effectively save fuel. According to relevant studies, EPS motors can reduce fuel consumption by 3% to 5%.

B. Improve controllability: The EPS motor can adjust the steering torque in real-time according to the vehicle's speed and steering angle, making the steering smoother and more flexible.

C. Reduce noise: The EPS motor is driven by an electric motor and does not require an additional hydraulic pump, so the noise is lower.

D. Improve safety: EPS motors can automatically cut off power in the event of a collision with the vehicle to avoid fire caused by electrical sparks.

4. Global market size and development trends of EPS motors

The electric steering market size is expected to exceed US$130 billion by the end of 2036, with a compound annual growth rate of 14% during the forecast period from 2024 to 2036. The main reason for market growth is the increase in demand for commercial applications. Compared with traditional mechanical hydraulic steering systems, electric power steering motors have the advantages of good steering flexibility, control stability, low temperature resistance, and low energy consumption. Therefore, the automobile engine power steering system shows great vitality and will gradually replace the traditional driving system.

Asia Pacific market forecast:

The Asia-Pacific electric power steering market is expected to account for the largest revenue share at approximately 37% by the end of 2036. In particular, the increase in automobile production in developing countries such as China, India, Japan, and South Korea is a major growth factor for the market. As electric power steering systems become more advanced, automakers are increasingly incorporating them into the production lines. These systems are powered by electric motors and provide power assistance when turning the steering wheel. Using these auxiliary devices to turn the steering wheel, the driver can control the vehicle more easily and with less effort.

North American market statistics:

The North American electric power steering market is expected to hold a significant share during the forecast period. The growing demand for electric vehicles, coupled with relevant national legislation and subsidies, is the major driver of market growth. Strong disposable income and rising living standards in the region are also expected to drive growing demand for luxury and passenger vehicles.

The use of electric power steering systems is becoming increasingly popular due to their ability to provide better, more precise steering and greater fuel efficiency. Increased demand for luxury and passenger cars has led to the need for more efficient and comfortable power steering systems.

Things to note when looking for EPS motor production line manufacturers

A. Manufacturer strength: EPS motor assembly equipment is a complex set of equipment that requires certain technical strength to produce. Therefore, when choosing a manufacturer, you must understand its production scale, production experience, technical level, etc. Consult first and then conduct a site visit.

B. Equipment quality: Understand the yield rate of the products produced by the equipment, the achievable efficiency and the motor compatibility range, etc. Carefully check the material, workmanship, accuracy of the equipment, and the testing of important processes of motor products, etc.

C. In-sales and after-sales services: the process of equipment design and equipment delivery, as well as after-sales guarantee, training, maintenance and inventory reserves of commonly used equipment parts.

HONEST’s advantages in EPS motor assembly equipment

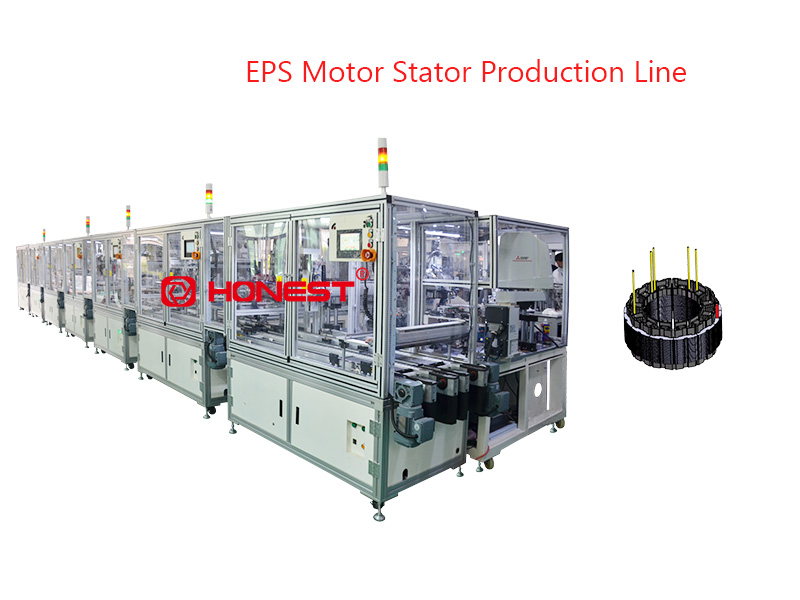

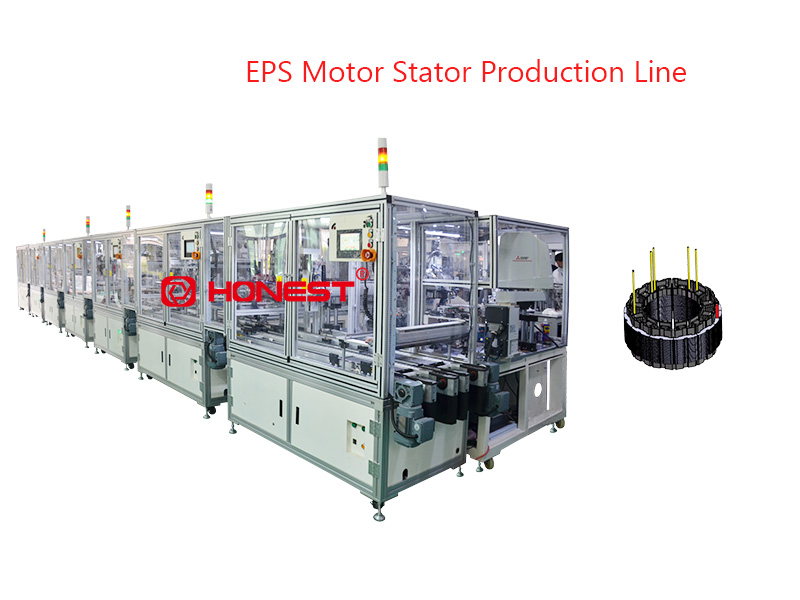

A. There are customer cases of mature EPS motor stator and rotor assembly lines, which have been successfully produced in the customer's factory;

B. The equipment solution design team has rich experience in the motor industry. Some senior engineers have more than 10 years of experience in the motor industry, and the design is more in line with customer needs;

C. Multiple loading modes are optional;

D. Economical and precision testing equipment can be selected;

E. It has advantages in winding and can realize single winding, double winding, triple winding and quadruple winding;

F. The busbar can realize automated assembly;

G.EPS motors have high requirements for dimensional accuracy. They usually require the inspection of the motor's characteristic dimensions, such as terminal position, housing roundness, concentricity of the sensing magnet, etc. We will provide corresponding solutions.

HONEST has focused on electric vehicle and fuel vehicle motor winding and assembly equipment for more than 17 years, and has many cooperation cases with well-known domestic and foreign automobile, auto parts and motor manufacturers. We will provide semi-automatic or fully automatic EPS motor assembly equipment solutions according to your detailed requirements.

If you are interested in EPS motor assembly line, please feel free to contact us so that we can help you make the right choice.