1. The Characteristics of Precision Winding

High precision: During the winding process, the size, shape, number of layers, number of turns, and other winding parameters of the coil are strictly controlled to meet the design requirements.

Automation: Modern precision winding is usually completed by automated winding machines. These machines can accurately wind coils according to preset programs, improving production efficiency and consistency.

Multi-axis Control: Precision winding machines may contain multiple independently controlled axes for winding multiple coils at the same time or winding complex coil structures.

Tension Control: The tension of the wire during the winding process needs to be accurately controlled to ensure the tightness and uniformity of the coil and avoid affecting its electrical performance.

Programmability: Precision winding machines usually allow operators to adjust winding parameters according to different coil design requirements.

Quality Inspection: After winding is completed, the coil will undergo a series of quality inspections, including electrical performance testing and physical size inspection, to ensure that it meets the standards for precision winding.

Safe Operation: Precision winding machine designs usually include safety features, such as emergency stop buttons, safety door interlocks, and so on, to ensure the safety of operators.

Easy Maintenance: The design of the precision winding machine focuses on the convenience of maintenance to reduce downtime and improve production efficiency.

Wide Range of Applications: Precision winding technology is suitable for electronic and electrical product manufacturing of all sizes, from small smart electronic equipment to large industrial transformers.

2. The Technical Principles of Precision Winding

Precision Wiring: Precision winding technology requires that the number of turns and feed amount of each layer of the coil can be accurately set to meet the requirements of high-density wiring. It is usually suitable for coils with thicker wire diameters and fewer turns.

Electronic Cam Control: The inner winding machine uses electronic cams to control the movement of the three axes of the upper and lower axes, indexing axes, and wire arrangement axes to achieve precise winding movements.

Linear Interpolation: During the winding process, the positioning and synchronous movement of each axis can be accurately controlled through the linear interpolation algorithm.

Foot-binding Process: A specific algorithm is used to realize the foot-binding action of the winding machine during the winding process, which usually involves the arc motion of two axes and linear positioning of the other axis.

Cylinder Control: The swing rod flipping, stator clamping, wire trimming, and other actions required during the winding process can be realized through the cylinder control algorithm, which increases the flexibility of the process.

Stop Angle Setting: The winding command can set multiple stop angles to facilitate subsequent process operations after the winding is completed.

Program Management and Editing: Precision winding machine users can edit and store winding programs as needed to adapt to different process requirements.

High Speed and responsiveness: The precision winding machine can operate at high speed, ensuring the stability and control accuracy of the winding machine during operation.

Performance Stability: The use of high-performance controllers and drivers ensures the stability and control accuracy of the winding machine during operation.

3. The Advantages of the Precision Motor Winding Machine

High Precision: Precision winding machines can achieve very precise coiling, which can meet the needs of electronic components that require high performance and stability.

High Stability: The design and manufacture of precision winding machines usually take into account the need for long-term stable operation, ensuring consistency and reliability in the continuous production process.

High Degree of Automation: Modern precision winding machines are usually equipped with automated control systems, which can reduce manual intervention and improve production efficiency and operational safety.

Customizability: Precision winding machines can be customized according to different application needs to meet the size, shape, and performance requirements of specific coils.

Easy to Operate: The user-friendly interface and easy operation allow non-professionals to get started quickly, reducing dependence on professional operators.

Energy Saving and Environmental Protection: Precision winding machines take energy efficiency into consideration when designing, and usually use energy-saving drive systems and optimized processes to reduce energy consumption.

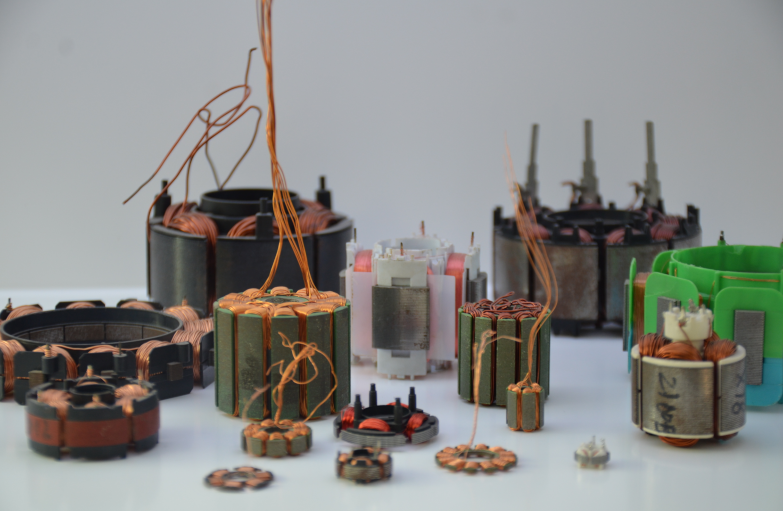

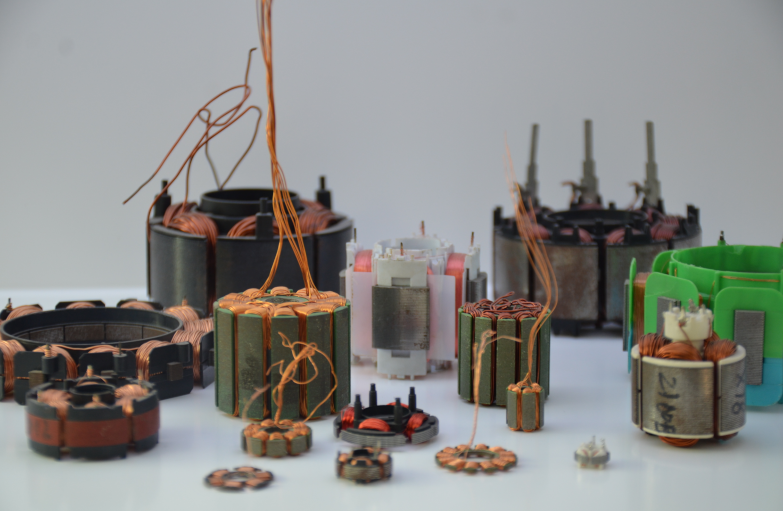

Wide Range of Applications: Precision winding machines can be used to manufacture a variety of coils, including but not limited to inductors, transformers, motors, and so on, with a wide range of applications.

Quality Control: Precision winding machines are usually equipped with online detection and quality control systems, which can monitor product quality in real-time and ensure that products meet high-standard quality requirements.

Low Maintenance Costs: The design of the precision winding machine focuses on durability and ease of maintenance, reducing maintenance costs and downtime.

Market Competitiveness: These advantages of precision winding machines make them highly competitive in the market and can meet the needs of the high-end market.

4. The Application of Precision Winding Technology in the Automotive Field

Precision winding technology is widely used in many industries due to its high precision and high stability. Its application in the automotive field will be described below:

Motor: The automobile motor is an important part of the automobile power system, and its performance directly affects the power, economy, and operability of the automobile. Precision winding technology can be used to manufacture motor components such as starters, generators, and alternators for automobile engines, improving the efficiency, power density, and reliability of motors.

Transformer: The automobile transformer is an important component that converts the DC power for the vehicle’s lighting, audio, air conditioning, and other electrical equipment. Precision winding technology can be used to manufacture excitation coils, high-voltage coils, and other components of automotive transformers to improve the efficiency, power density, and voltage resistance of the transformer.

Sensor: Automotive sensors are important components that sense various operating conditions of the car and provide data for the vehicle’s control system. Precision winding technology can be used to manufacture coil components of automotive sensors to improve the sensitivity, accuracy, and reliability of the sensor.

Solenoid Valve: The automobile solenoid valve is a key component that controls the air intake. Exhaust, fuel injection, and other systems of the automobile engine. Precision winding technology can be used to manufacture coil components of automotive solenoid valves to improve the response speed, control accuracy, and reliability of solenoid valves.

The advantages brought by the application of precision winding technology in the automotive field:

Improve the Performance of Auto Parts: Precision winding can improve the overall performance of the vehicle by improving the operating efficiency, power density, accuracy, and reliability of auto parts.

Reduce the Cost of Auto Parts: Precision winding can improve the efficiency and yield of winding, and reduce production costs.

Improve the space utilization of the vehicle: Precision winding can make the auto parts smaller and lighter, thereby improving the space utilization of the car.

5. The Future Development Trend of Precision Winding Machines:

Automation and Intelligence: With the advancement of Industry 4.0, future precision winding machines will be more automated and intelligent, integrating advanced sensors, machine vision, and artificial intelligence algorithms to achieve self-optimization and predictive maintenance.

Multi-axis Robot Technology: Multi-axis robots will play a greater role in the precision winding process, providing higher flexibility and adaptability to produce more complex coil structures.

Simulation and Emulation Technology: Advanced simulation and simulation software will be used to optimize winding design and process, reducing the cost of prototyping and testing.

Environment Friendliness and Sustainability: Precision winding technology will pay more attention to environmental impact and use recyclable materials and energy-saving processes to support sustainable development.

Customized Production: As the market demand for customized products increases, precision winding technology will support smaller batches and diversified production.

Miniaturization and Lightweight: Precision winding technology will support the production of smaller and lighter motors to meet the needs of portable devices and electric vehicles.

Modular Design: The winding machine will adopt a modular design to facilitate rapid adjustment and upgrade to adapt to different production needs.

6. About HONEST Automation

HONEST Automation focuses on motor winding assembly equipment with more than 18 years of R&D and production experience. We cooperate with many well-known automobile and motor manufacturers to provide customized automation equipment solutions and quotations.

Our stator and rotor winding machines are highly efficient, capable of producing in approximately one second, and boast a yield rate of up to 99%. These capabilities significantly save both time and money in the manufacturing process.

If you want to get more information about our motor precision stator winding machine, please contact us, look forward to hearing from you.